Vertical type one-way combination valve for reciprocating type gas-liquid two-phase mixture conveying pump

A reciprocating, combined valve technology, applied in the direction of variable capacity pump components, pump components, liquid fuel engines, etc., can solve the problems of reducing the service life of the valve group, unfavorable gas phase medium discharge, small flow area, etc., to reduce pressure. Loss and waste of energy, improve overall operating performance, increase the effect of flow channel area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

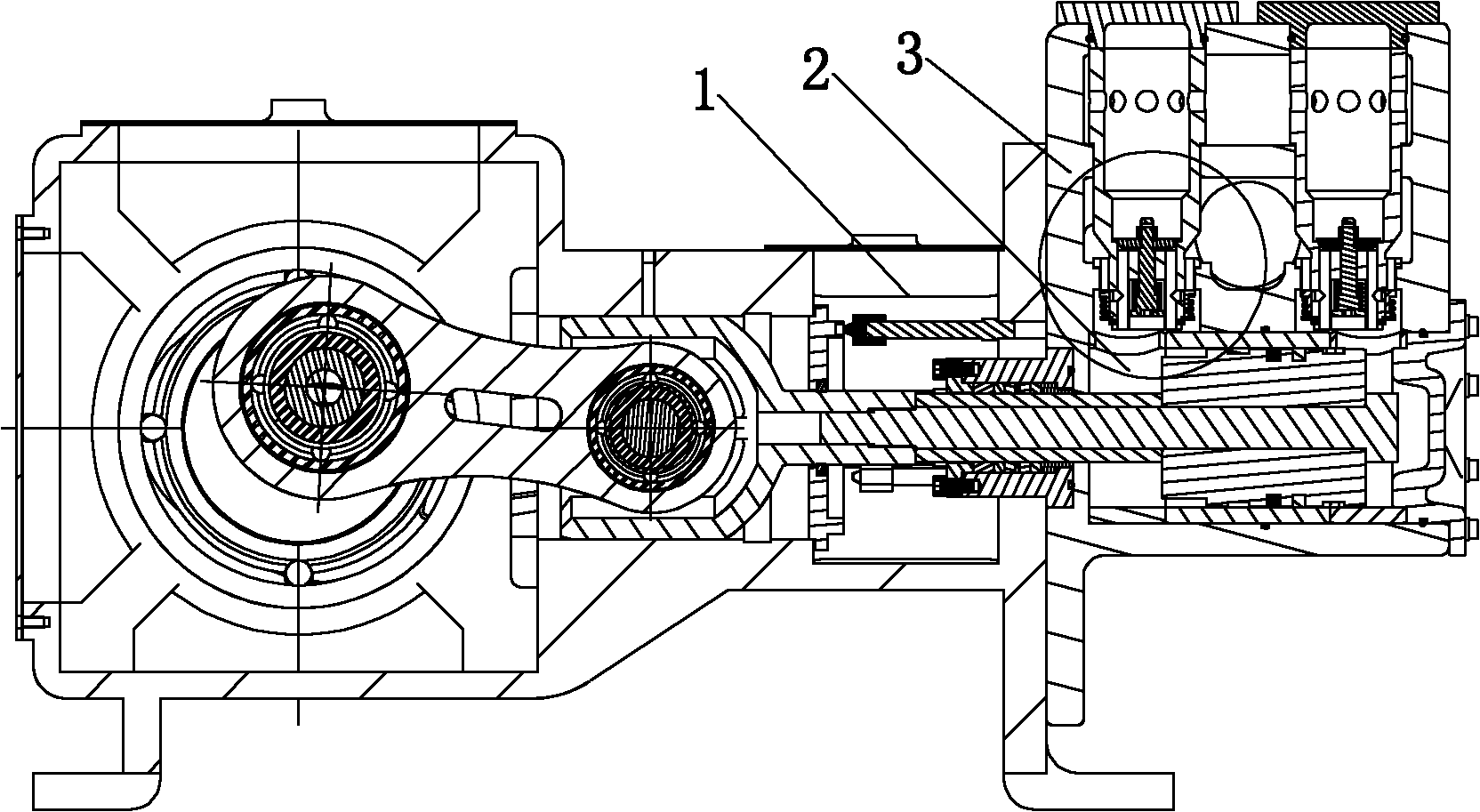

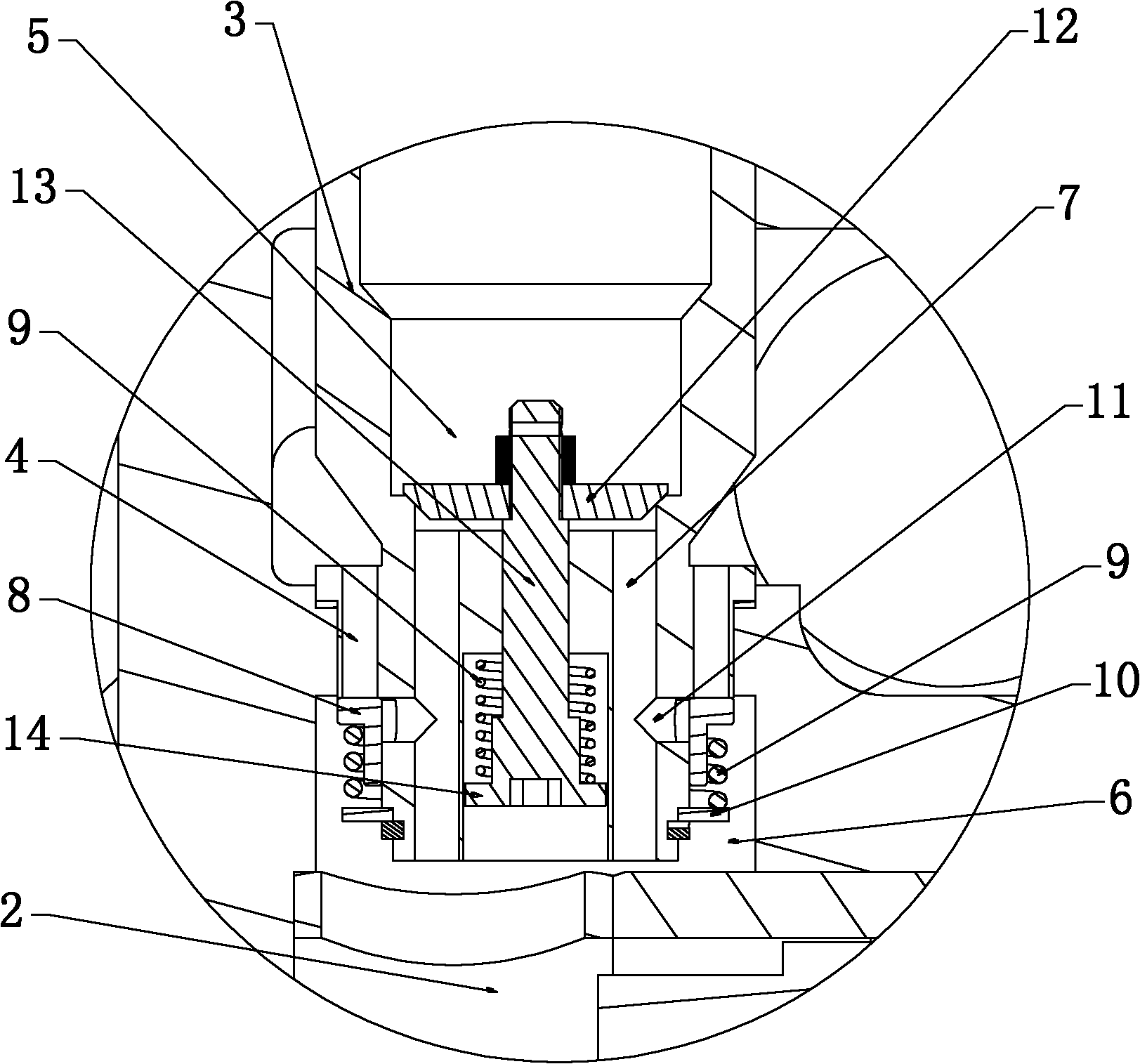

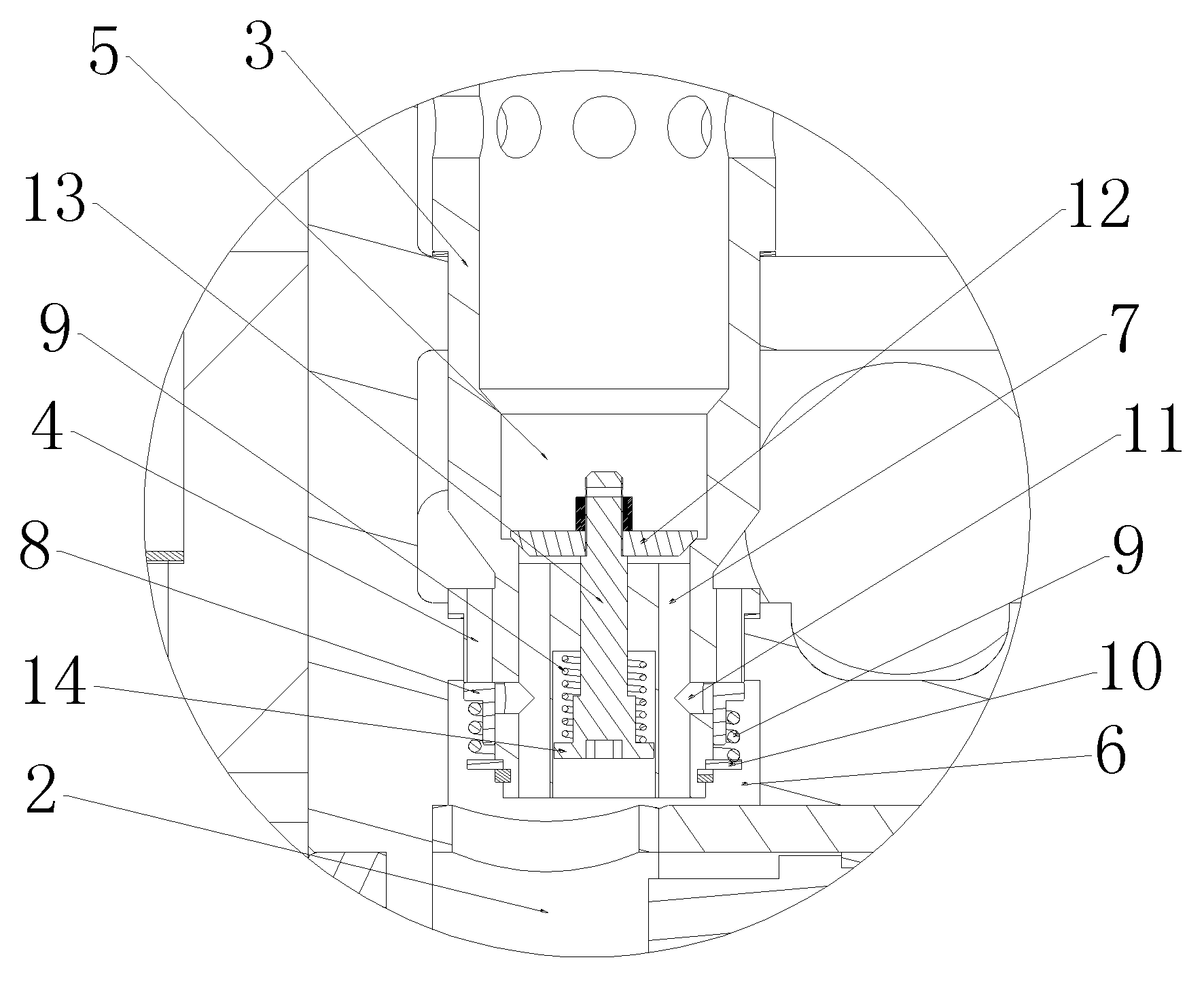

[0012] Such as figure 1 , figure 2 As shown, the vertical one-way combined valve for the reciprocating gas-liquid two-phase mixed delivery pump described in this embodiment mainly includes a valve body 3, a valve inlet 4, a valve outlet 5, an inlet chamber 6 and an outlet chamber 7. The valve body 3 is vertically arranged at the opening of the cavity 2 of the pump body 1, the valve outlet 5 is arranged on the inner ring of the valve body 3, the valve inlet 4 is arranged on the outer ring of the valve body 3, and a valve ring 8 is arranged in the inlet cavity 6 , a compression spring 9 is provided on the valve ring 8, and the compression spring 9 is limited by the stop ring 10 provided on the valve body 3, and a shunt hole 11 is provided on the valve body 3 between the inlet cavity 6 and the outlet cavity 7, The valve outlet 5 is provided with a valve plate 12, the valve plate 12 is connected with one end of the vertical rod 13, and one end of the vertical rod 13 in the outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com