Noise-reduction ball valve

A ball valve, noise reduction technology, applied in the direction of valve details, valve devices, valve energy absorption devices, etc., can solve the health hazards of operators, valve body and ball wear, high noise valve energy and other problems, to avoid turbulent flow , Reduce the medium flow rate, eliminate the effect of noise and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

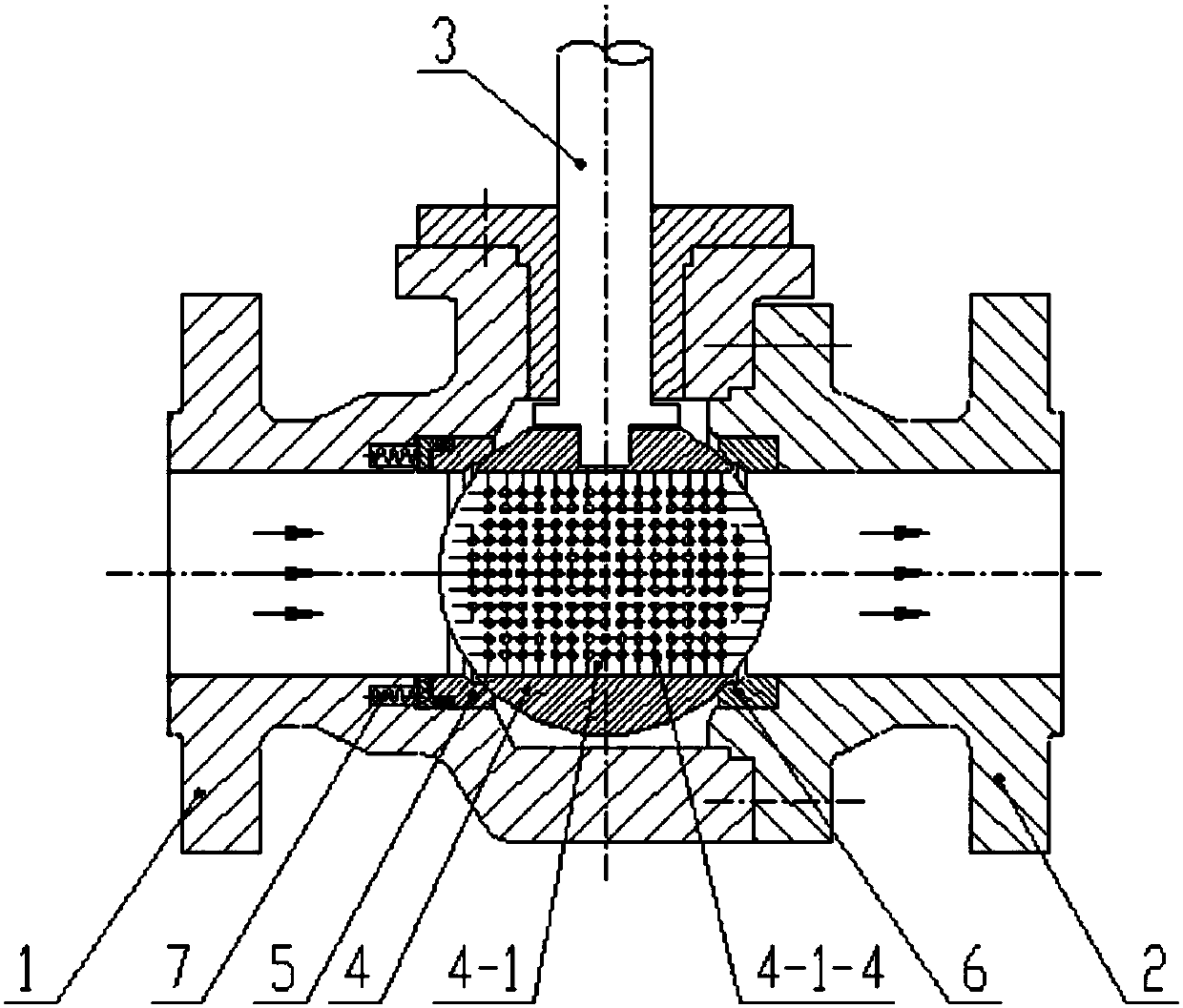

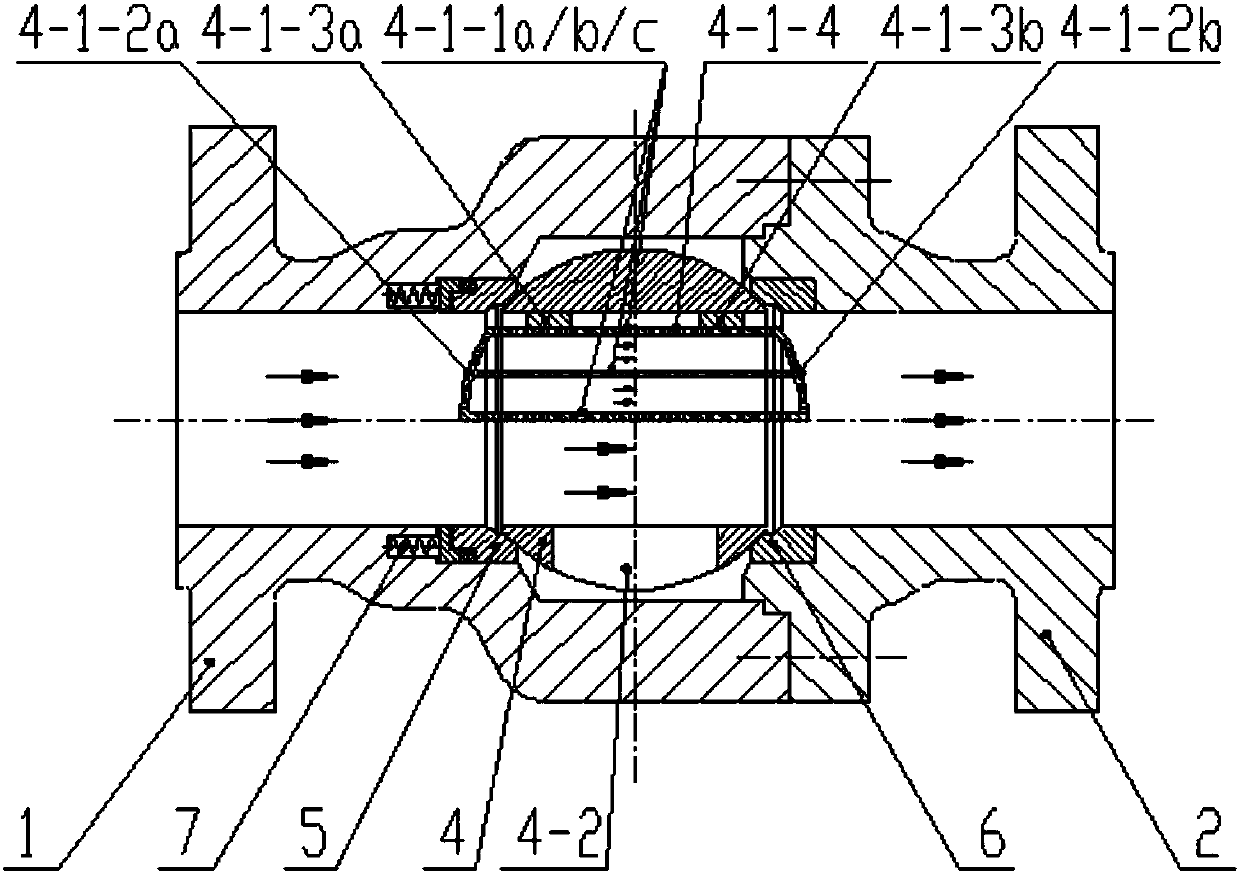

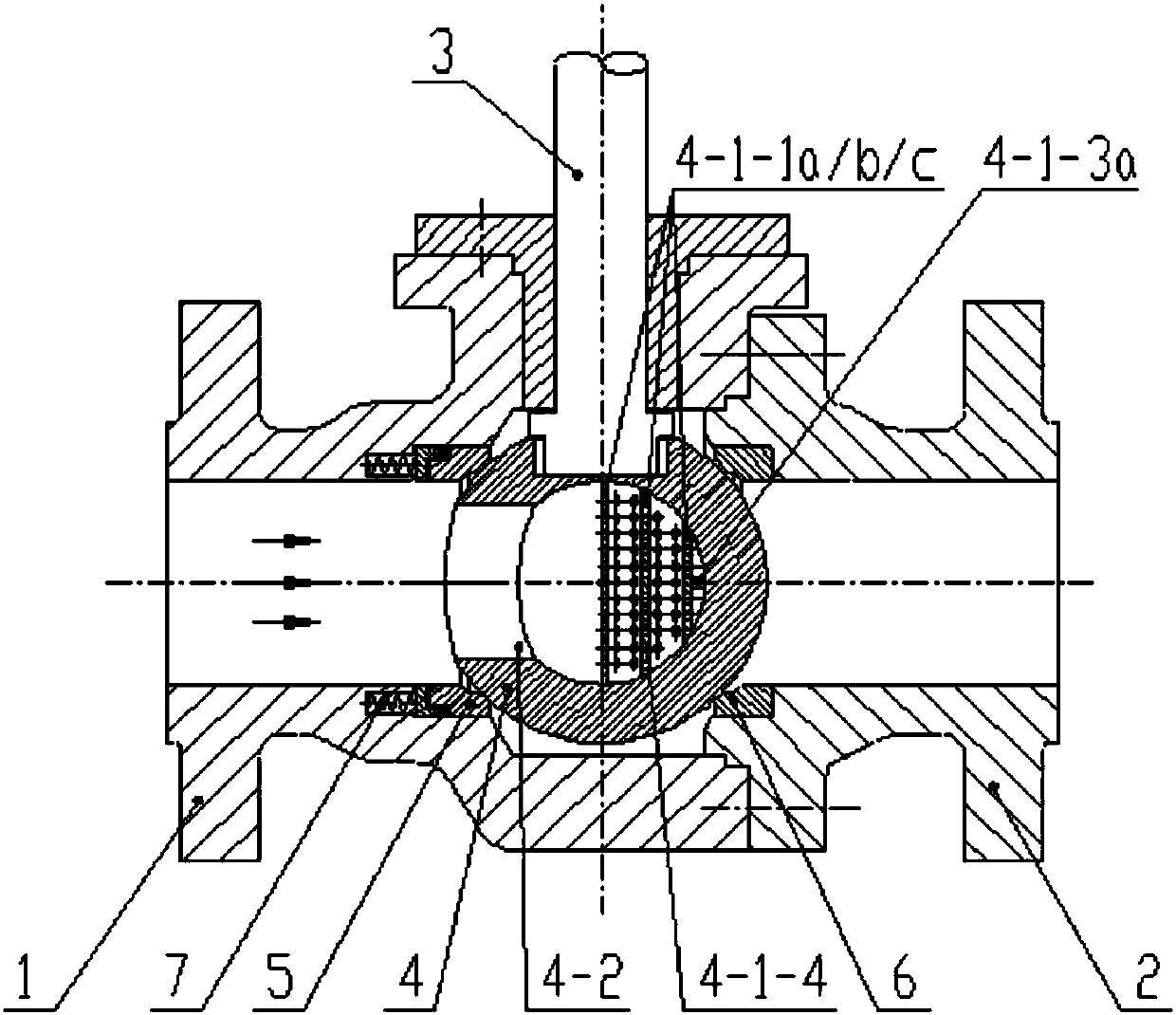

[0029] A noise reduction ball valve, the noise reduction ball valve is set as a floating ball valve structure, see Figure 1 to Figure 5 , the floating ball valve structure includes a valve body composed of a first valve body part 1 and a second valve body part 2, the valve body includes a ball 4, one side of the ball 4 is provided with an inlet valve seat 5, the The inlet valve seat 5 is provided with a spring 7, the other side of the ball 4 is provided with an outlet valve seat 6, the ball 4 forms a spherical seal with the outlet valve seat 6, and the valve stem 3 drives the ball 4 to rotate to complete switch action;

[0030] When the noise reduction ball valve is in the closed state, under the action of medium pressure, the ball 4 is displaced and pressed against the outlet valve seat 6 to form a spherical seal;

[0031] The inner part 4-1 is arranged in the flow channel of the sphere 4, and the inner part 4-1 includes at least two side plates 4-1-1, at least two end plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com