Silent throttling stop air release valve

A venting valve and silent technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of noise pollution, physical injury of workers, loud valve noise, etc., to reduce medium flow rate, stable operation, and reduce differential pressure vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the drawings and specific embodiments.

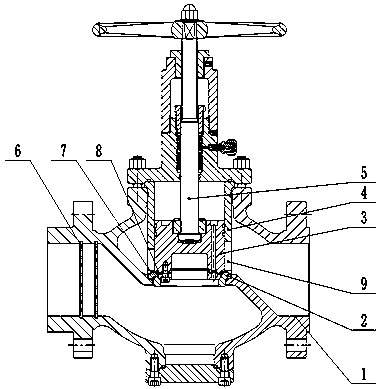

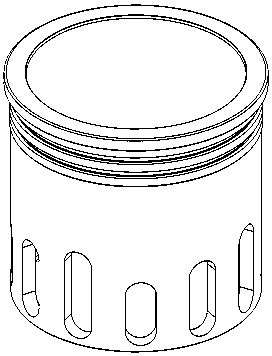

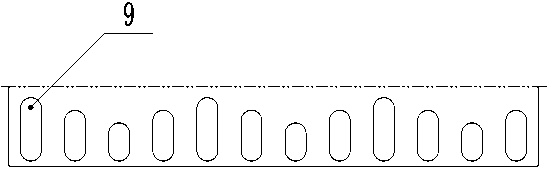

[0019] Such as figure 1 As shown, a mute throttle cut-off vent valve includes a valve body 1, a valve stem 5, a bracket, and a valve cover. It is characterized in that: the valve body 1 is provided with a noise reduction component and a disc component, and the noise reduction component includes a valve sleeve 4. The baffle plate 6; the valve sleeve 4 is cylindrical and is installed vertically on the same axis as the valve stem. The lower circumference of the valve sleeve 4 is provided with at least one set of throttle grooves 9 of different lengths; the throttle The bottoms of the grooves 9 are on the same axis, and the throttle grooves 9 are periodically symmetrically distributed; the baffle plate 6 is vertically arranged in the inlet channel of the valve body, and the baffle plate 6 is a hollow ring shape with an opening on the circumference. There are asymm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com