Condensate pipeline and method for improving vibration of condensate pipeline

A technology of condensate pipes and pipe bends, which is applied in the direction of pipes/pipe joints/fittings, siphon pipes, pipe components, etc., which can solve problems such as increased maintenance costs, maintenance personnel workload, threats to safe operation of units, and condensate system failures. Effect of increasing resistance, reducing vibration, and reducing medium flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] At present, it is generally believed that the main causes of pipeline vibration are:

[0043] a. The mechanical vibration of the equipment connected to the pipeline is transmitted to the vibration of the pipeline;

[0044] b. The pressure pulsation caused by the start and stop of the pump or the action of the valve induces the vibration of the pipeline;

[0045] c. Environmental factors cause pipeline vibration (such as wind, earthquake, etc.).

[0046] After analyzing the above reasons and taking improvement measures, the problem of large vibration and noise in the vertical pipe section has not been solved.

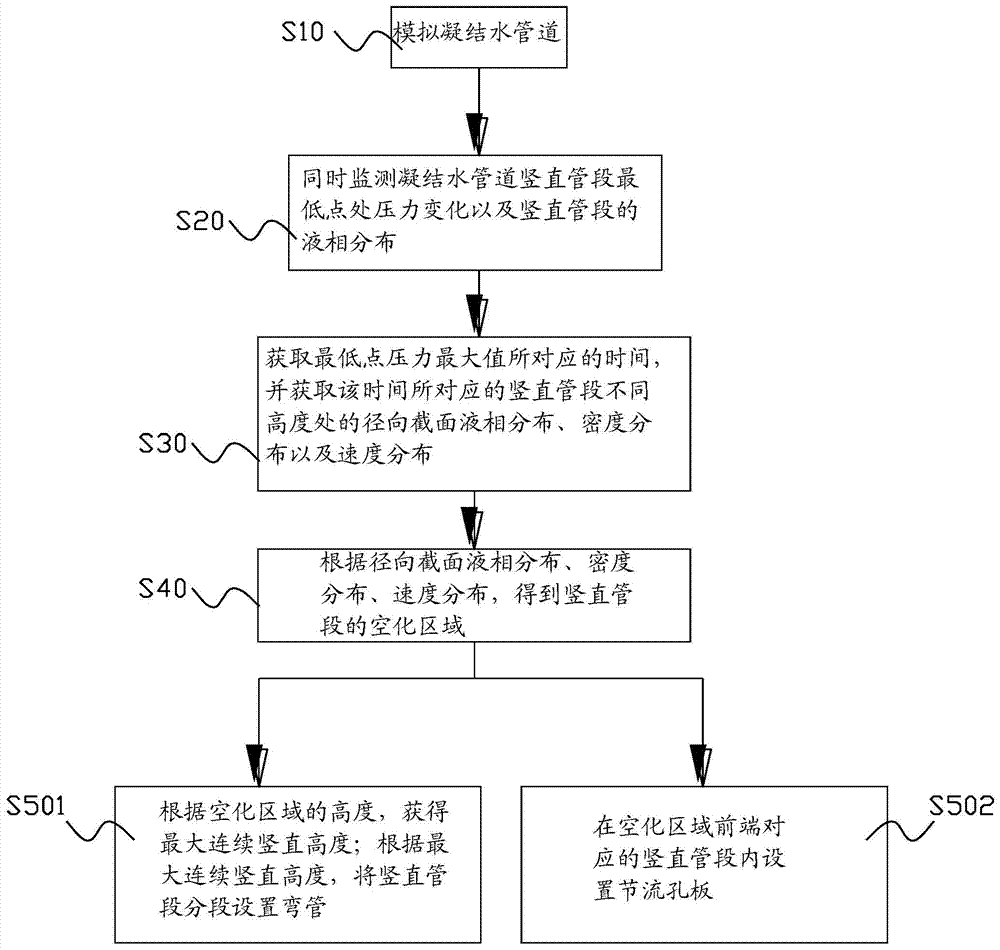

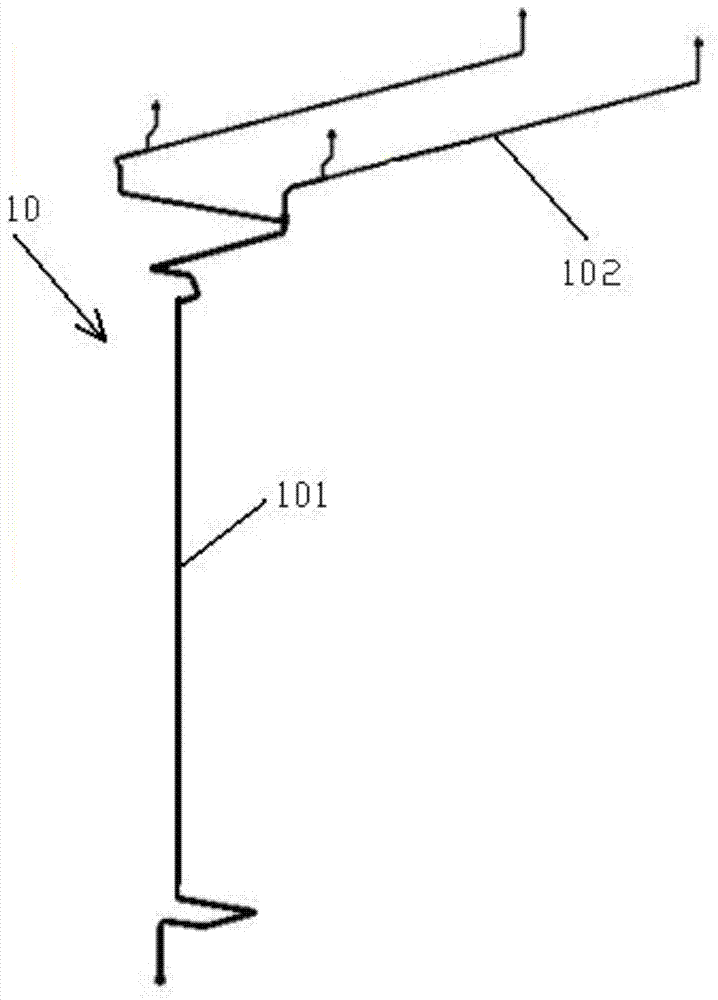

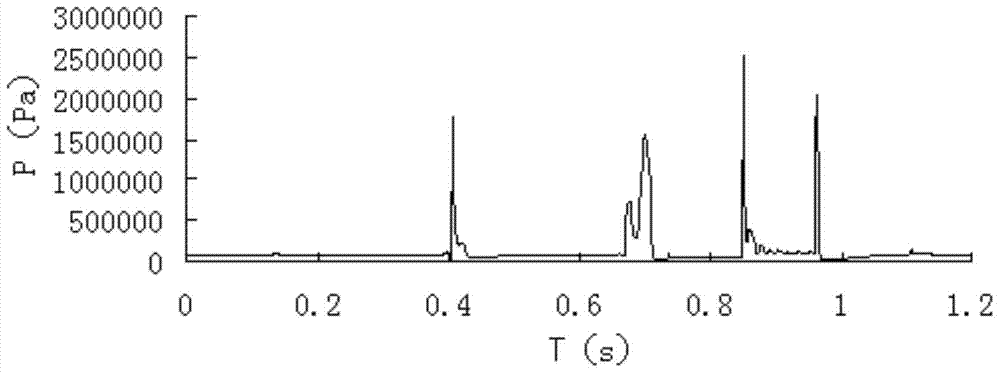

[0047] The invention finds out the main cause of the vibration of the vertical pipe section of the condensed water pipeline through experimental research, and provides a solution. In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com