Control valve, in particular angle control valve and double control valve, also in the form of a straight-seat valve and inc.lined-seat valve for extreme control applications

A technology for controlling valve and valve seat, which is applied in the direction of valve details, valve device, valve element and valve seat contacting parts, etc., can solve the problems of difficult disassembly, expensive tungsten carbide, long delivery time, etc., and achieves a solid structure. , Easy inspection and maintenance, the effect of reducing valve vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

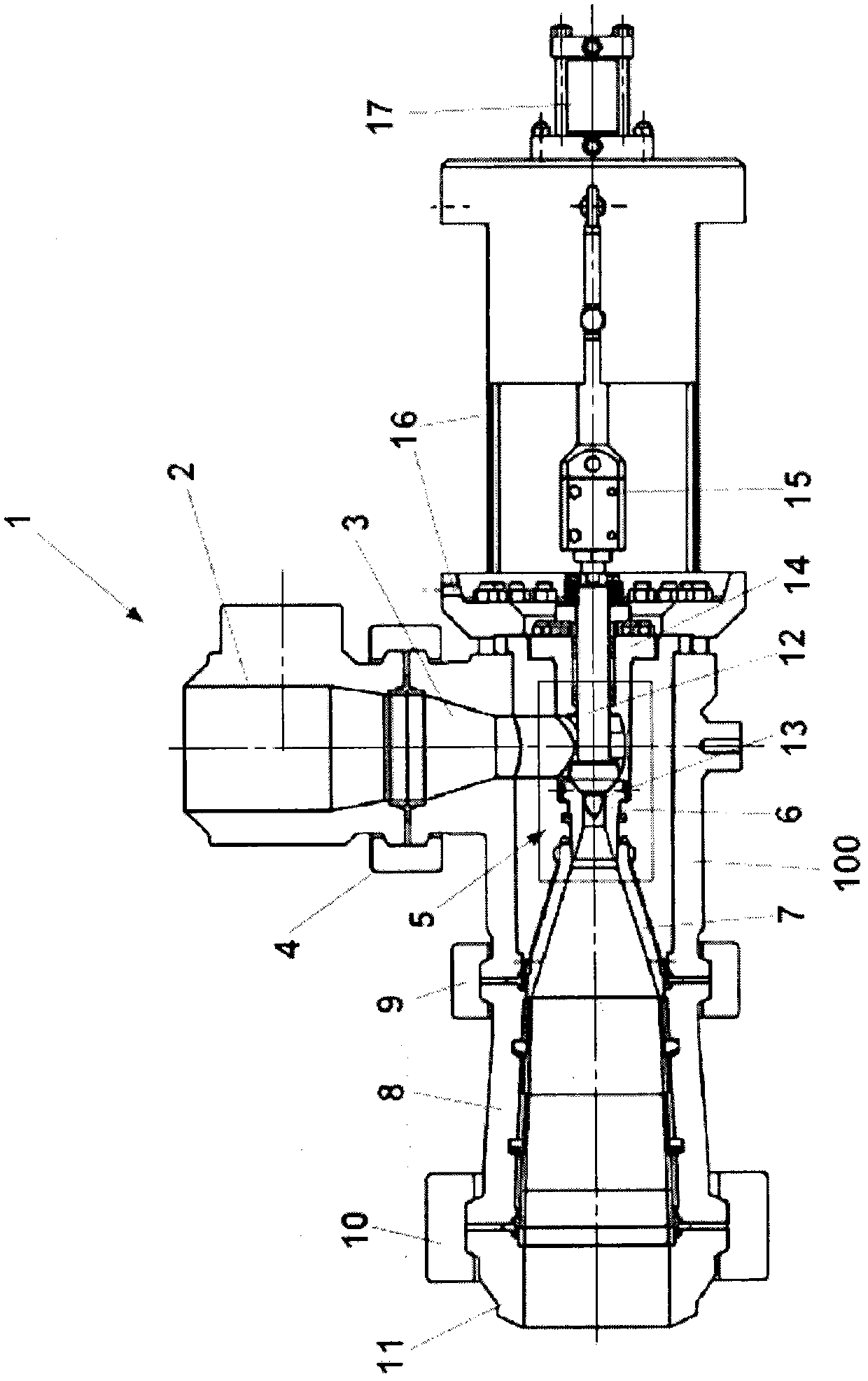

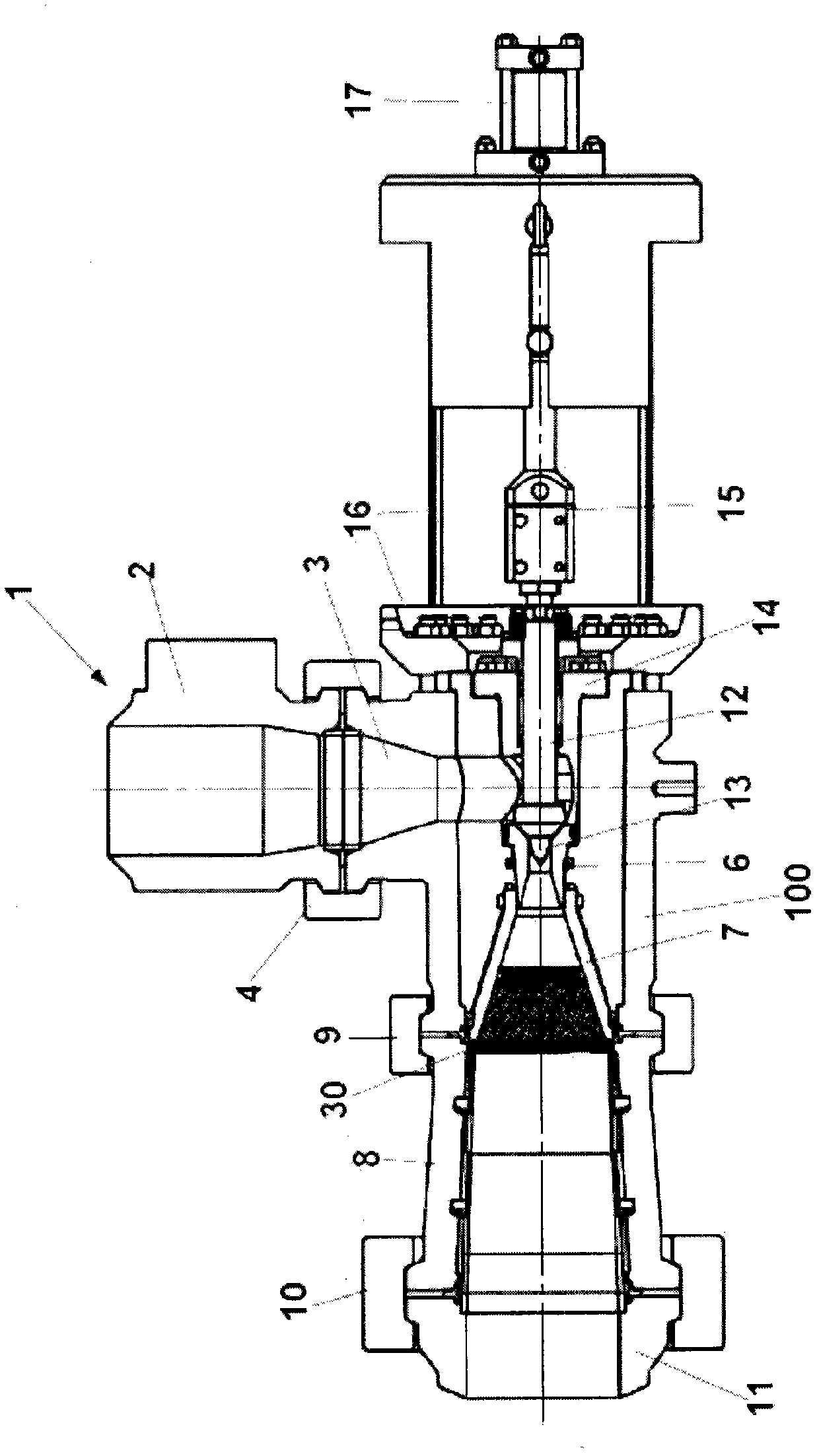

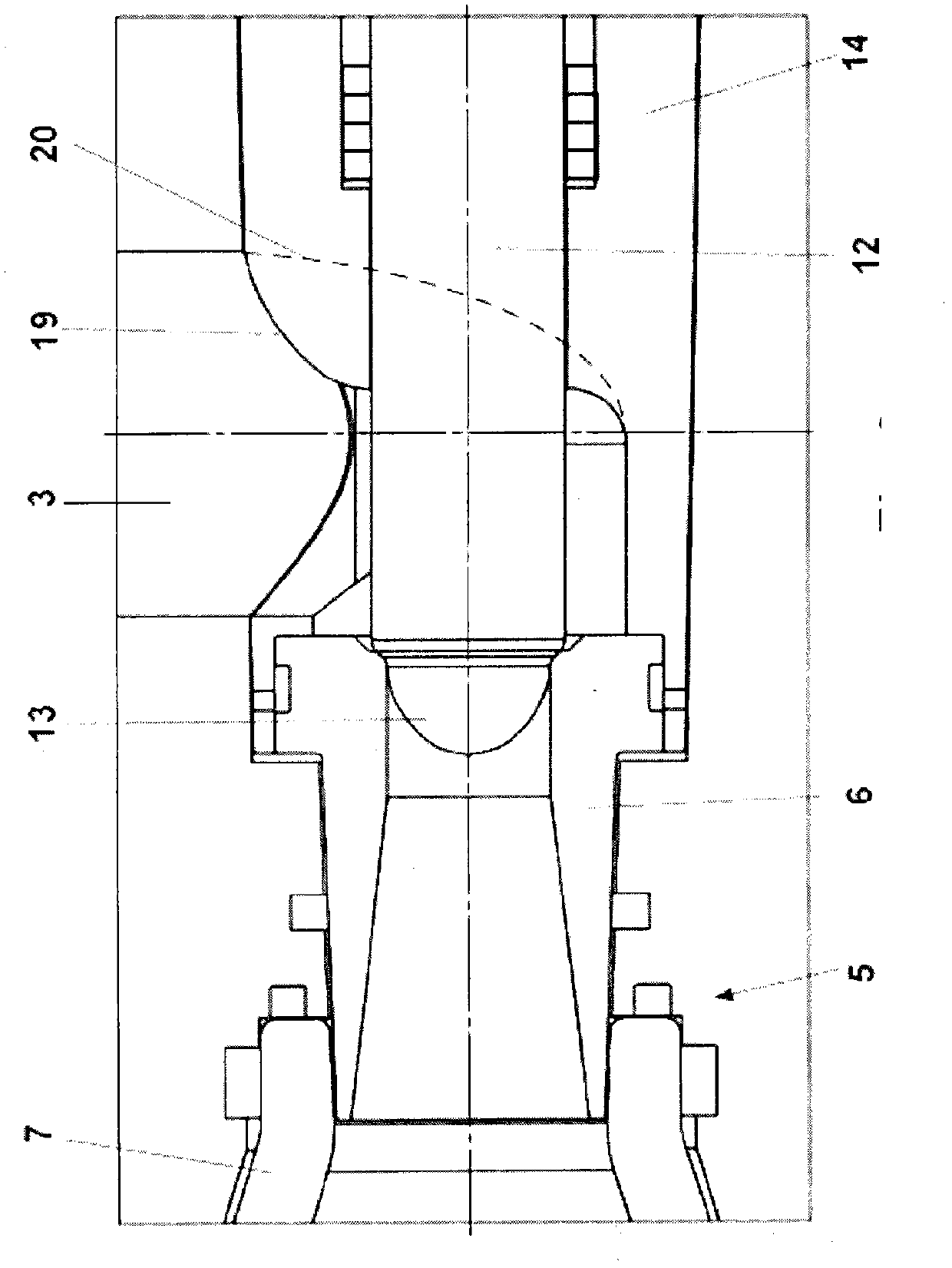

[0079] figure 1 with 2 The shown control valve with valve chamber 100 is designed as a single valve which is integrated with the main components of the system for conveying abrasive and corrosive media not shown in the figure, for example the feed opening 2 of the separator. An inlet channel 3 in the valve cavity 100 is immediately behind the feeding port 2 and is connected with the feeding port 2 by a ferrule or a flange. A valve seat assembly is arranged downstream of the inlet channel 3, including a valve seat support 5, an inner valve seat 6 and an outer valve seat 7, the latter being located downstream of the valve seat 6. Immediately behind the valve seat 7 is an outlet channel 8, which is connected with the valve cavity 100 and the valve seat 7 through a ferrule 9. The outlet channel 8 is connected to the downstream pipeline through a ferrule or a flange.

[0080] The valve plug 12 is designed to enter the inner valve seat 6 and forms a valve head at the end pointing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com