Novel triple-seal anti-scouring stop valve

A triple seal, anti-scour technology, used in shaft seals, lift valves, valve details, etc., can solve problems such as multiple repairs, sealing surface erosion, valve internal leakage, etc., to improve service life and reliability, and enhance resistance. Flushing ability, effect of reducing media flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

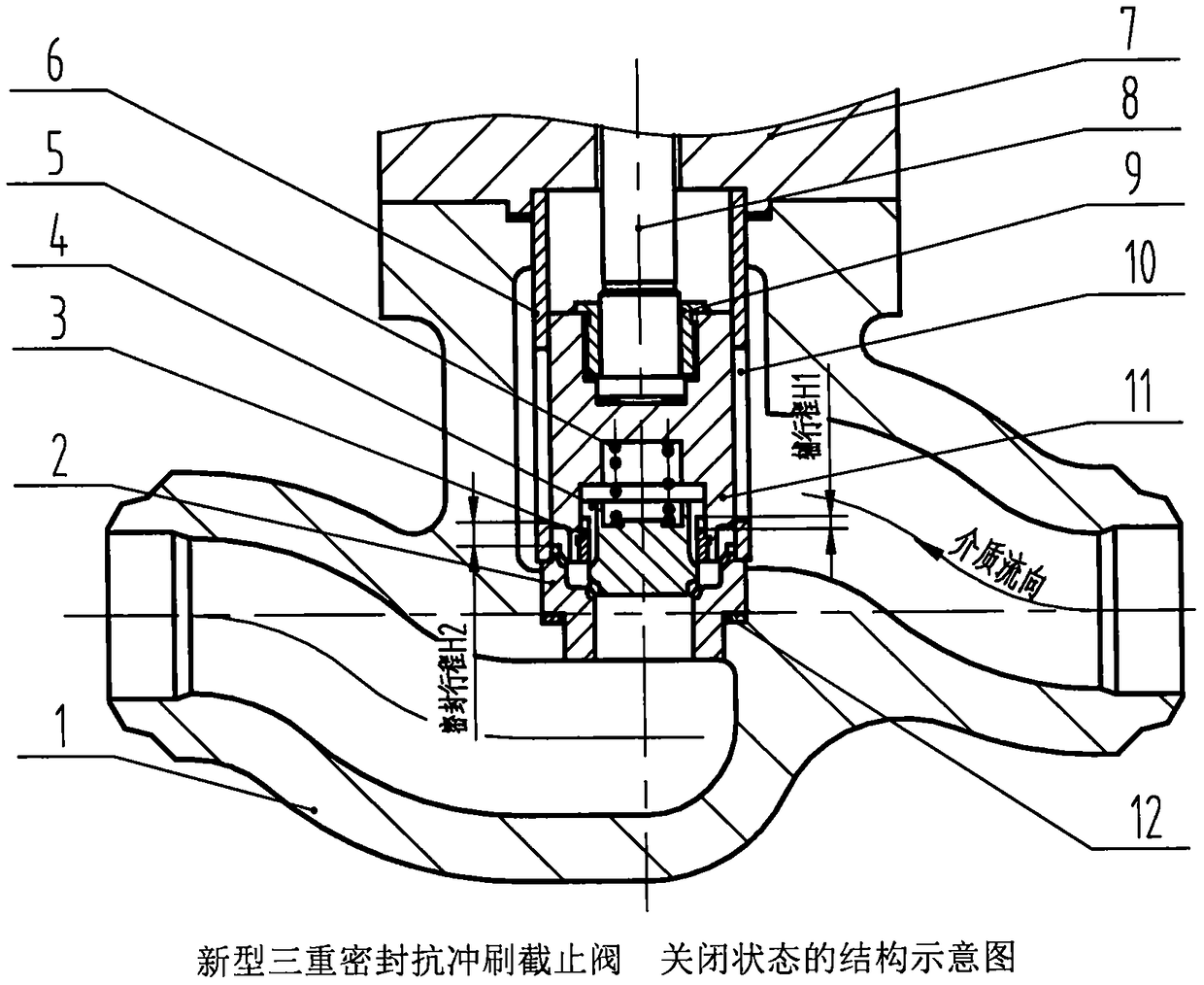

[0016] exist figure 1 In the shown embodiment, the valve seat (2) has two sealing surfaces, the valve seat (2) and the valve body (1) are sealed by a compression gasket (12), and the main valve disc (11) and the valve stem (8 ) is connected through the main valve gland (9), the valve stem (8) presses the main valve disc (11) to ensure the sealing of the main valve disc, and a spring (5) is set between the main valve disc (11) and the auxiliary valve disc (4) , the auxiliary valve disc (4) is pressed by the spring (5) to ensure the sealing of the auxiliary valve disc. The lower end of the main valve disc (11) is connected with the auxiliary valve gland (3), and the auxiliary valve gland (3) and the auxiliary valve An auxiliary stroke H1 is set between the petals (4).

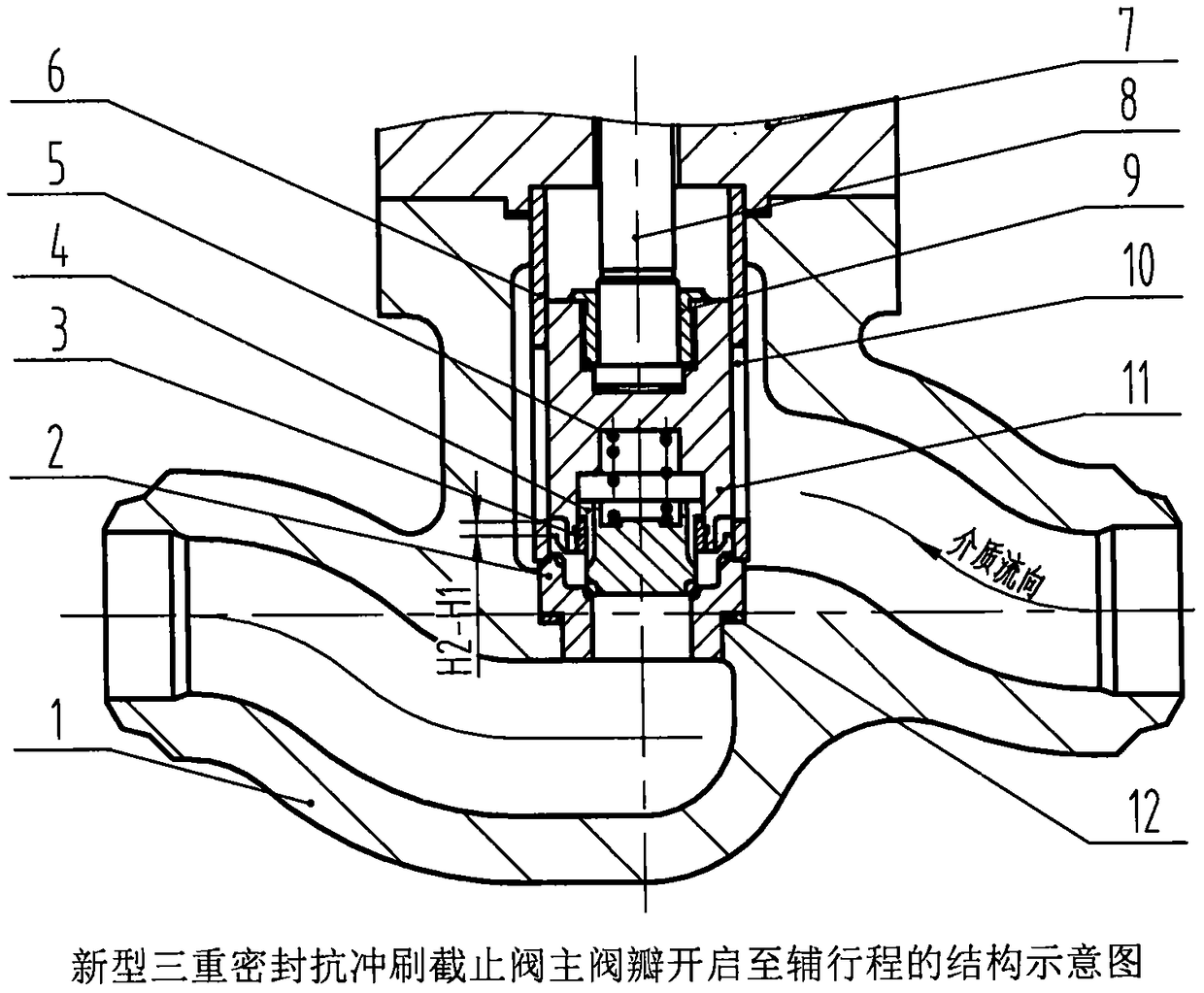

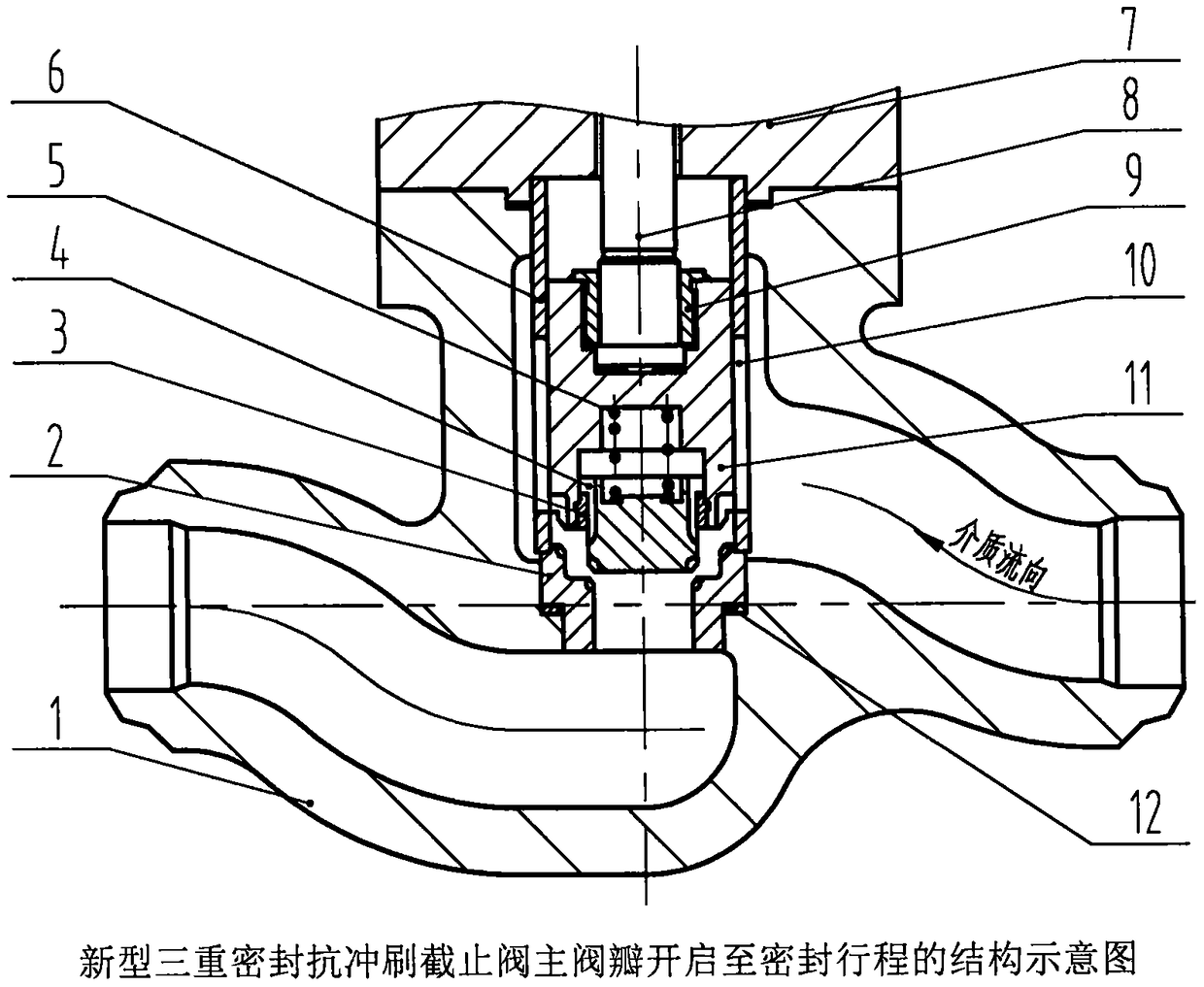

[0017] Such as figure 2 As shown, the valve stem (8) drives the main valve disc (11) to open and move up along the throttle sleeve (6) through the main valve gland (9). First, the main valve disc (11) leaves t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com