Flow passage component of high-temperature high-pressure coal chemical industry

A high-temperature, high-pressure, flow-passing component technology, applied to pump components, components of pumping devices for elastic fluids, pumps, etc., can solve problems such as short life, wear of pressure-bearing pump body and pump cover, and reduce vibration , Reduce erosion and wear, enhance the effect of passing capacity

Active Publication Date: 2011-01-05

XIANGYANG WU ER WU PUMP IND

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to overcome the problems that the pressure-bearing pump body and pump cover of the existing slurry pump are severely worn in the slag pool circulation station, and the service life is short, and a new high-temperature and high-pressure slurry pump flow-through component is designed and developed. structure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

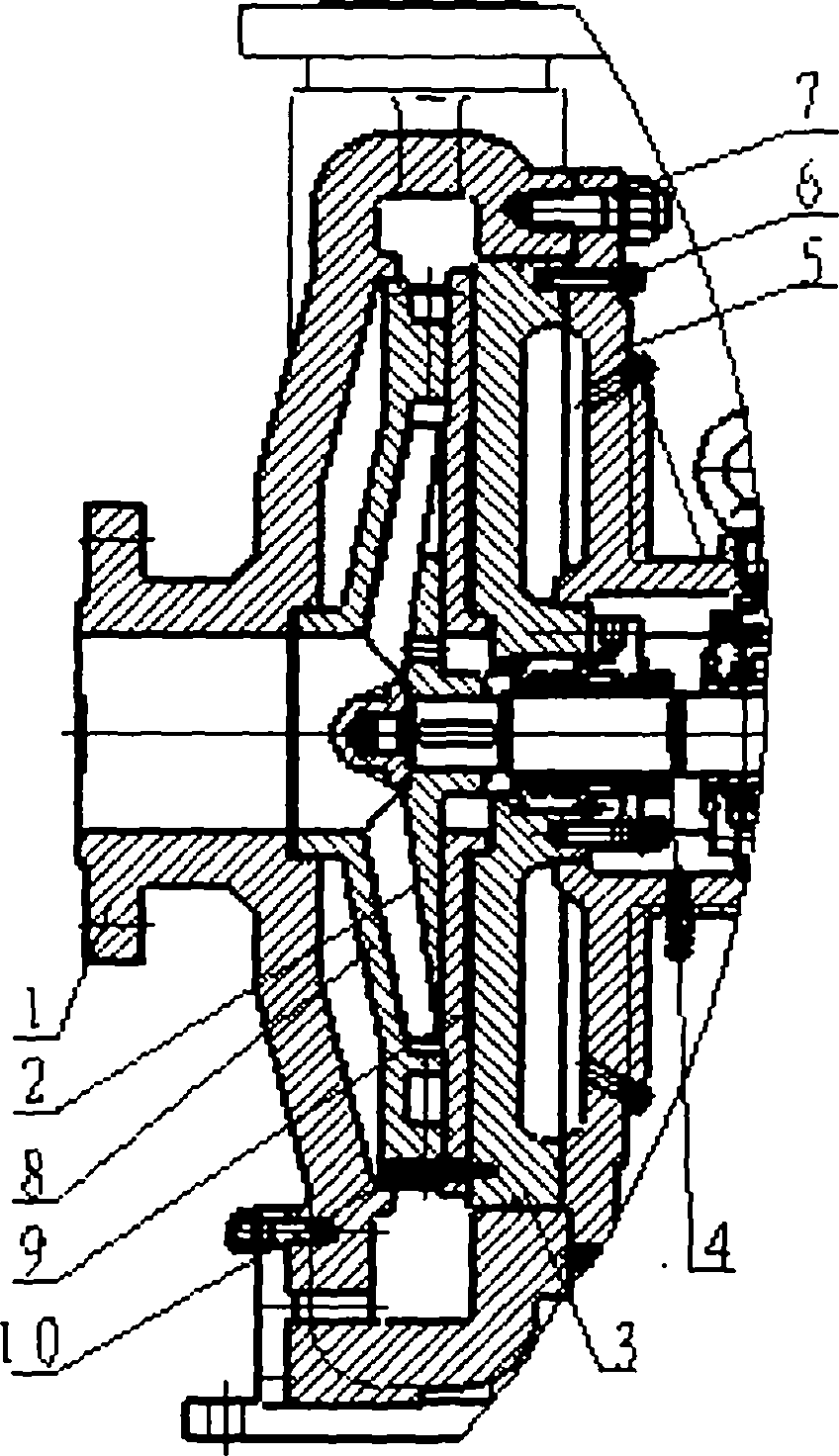

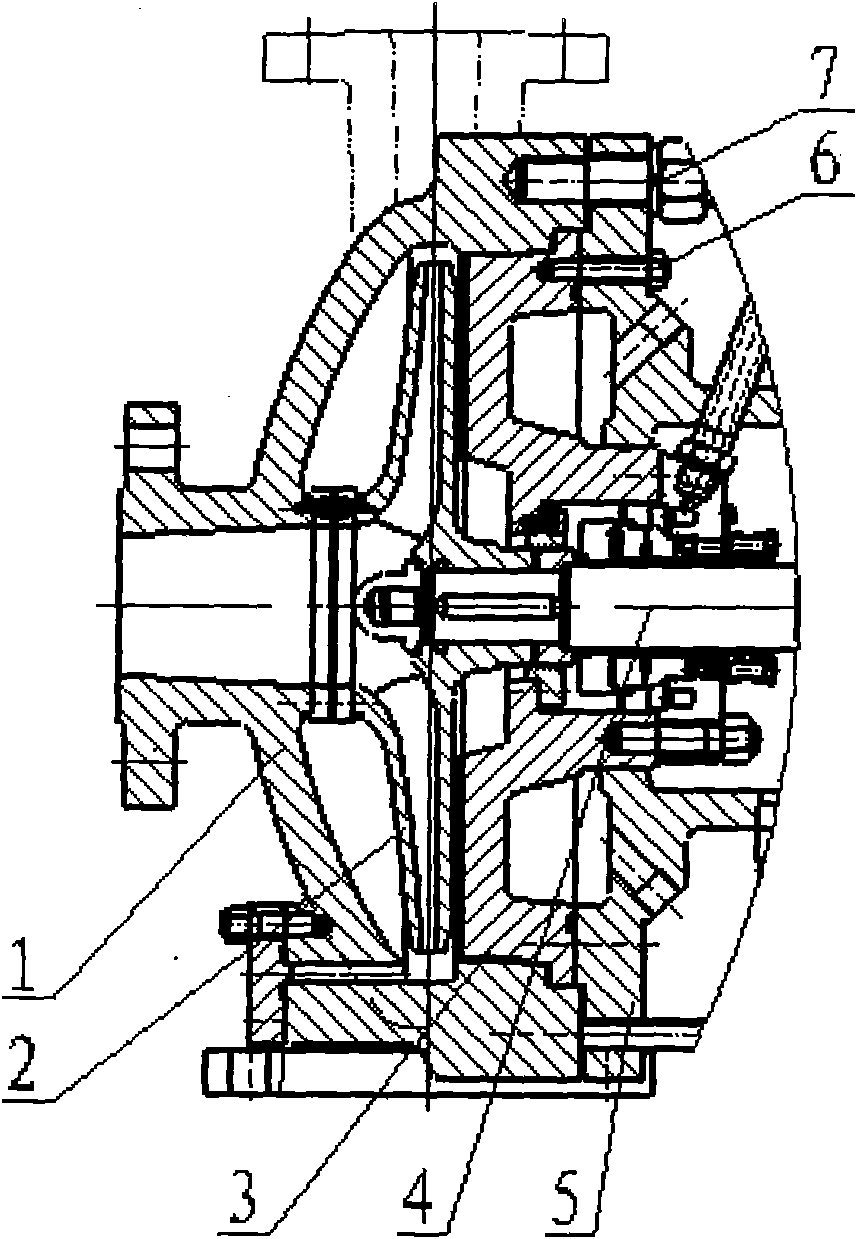

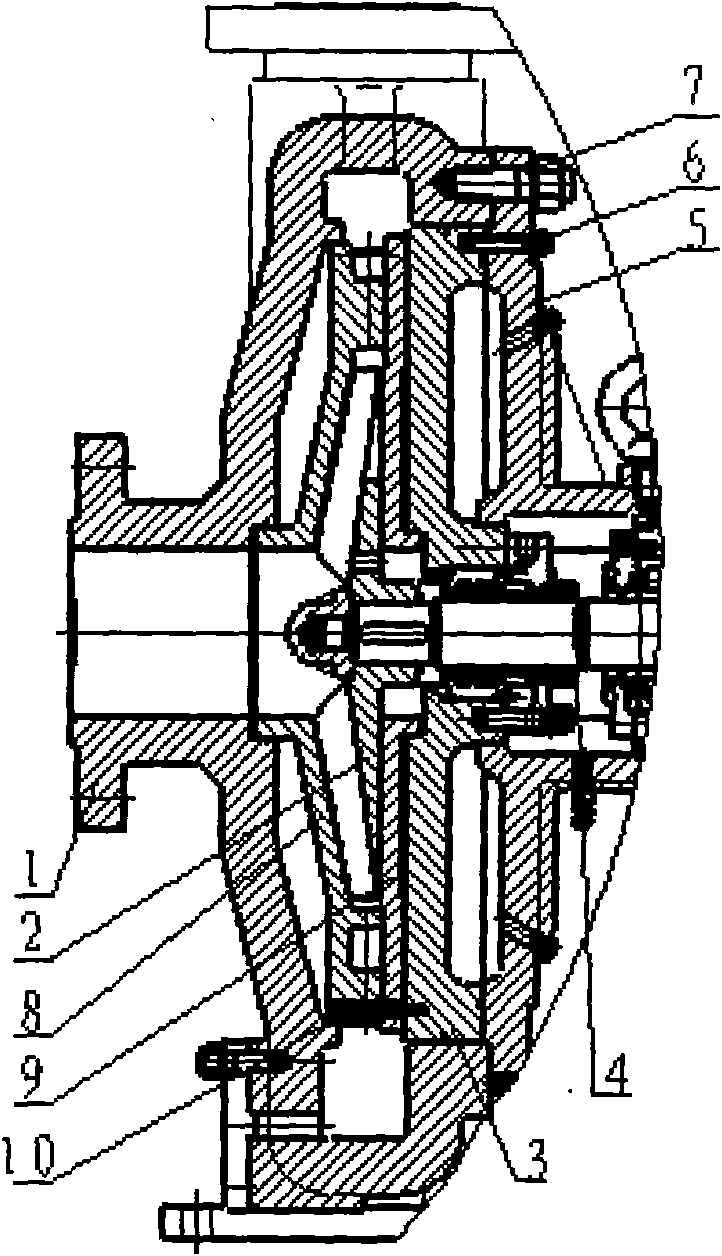

The invention relates to a flow passage component of a pump, in particular to a flow passage component of a high-temperature high-pressure coal chemical industry, belonging to the fluid machinery field. The flow passage component of the high-temperature high-pressure coal chemical industry comprises an impeller, a guide vane and a scaleboard; a female end of the scaleboard is located with a male end of an excircle surface of a large mouth end at right side of the guide vane in a matching way, a fastening screw penetrates through a cylindrical through hole to lead the guide vane and the scaleboard to be fixed on a pump cover, the impeller is arranged on a pump shaft and is arranged between the guide vane and the scaleboard. In the invention, the guide vane and the scaleboard are arranged in a pump body, the guide vane is used for protecting the pump body to reduce erosion wear of medium to the pump body, and the scaleboard can protect the pump cover to reduce abrasion of the medium to the pump cover. The flow passage component aims at overcoming the problems that a bearing pump body and the pump cover of the existing slurry pump are seriously wore at a circulating work station of aslurry tank, and the service life is short, thereby developing a new flow passage component of the high-temperature high-pressure coal chemical industry, improving the service life of the pump and reducing the maintenance cost of the pump.

Description

High temperature and high pressure coal chemical slurry pump flow parts technical field The invention relates to a structure of a flow-passing part of a pump, in particular to a flow-passing part of a high-temperature and high-pressure coal chemical slurry pump, which belongs to the field of fluid machinery. Background technique Coal gasification is the leading and key technology in the development of coal chemical industry. In theory, any organic compound can be synthesized or extended through synthesis gas. After coal is gasified into synthesis gas, the synthesis gas can be used for civil use, heating, power generation or chemical production. In the domestic coal chemical industry, the pressurized gasification technology represented by TEXACO (Texaco), SHELL and GSP technology is widely used in the coal gasification process equipment. The core equipment in the pressurized gasification slag removal system; its stability directly affects the safe operation of the entire ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F04D7/04F04D29/02F04D29/44F04D29/22

Inventor 李落成梁晨阳吴志宏杨勇

Owner XIANGYANG WU ER WU PUMP IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com