A keyway type safety valve

A safety valve and keyway technology, which is applied to pump components, parts of pumping devices for elastic fluids, liquid fuel engines, etc., can solve the problems of large spring force, large valve core area, and high specific pressure of the sealing surface. Achieve the effect of improving reliability and service life, good stability of double guides, and improving spring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

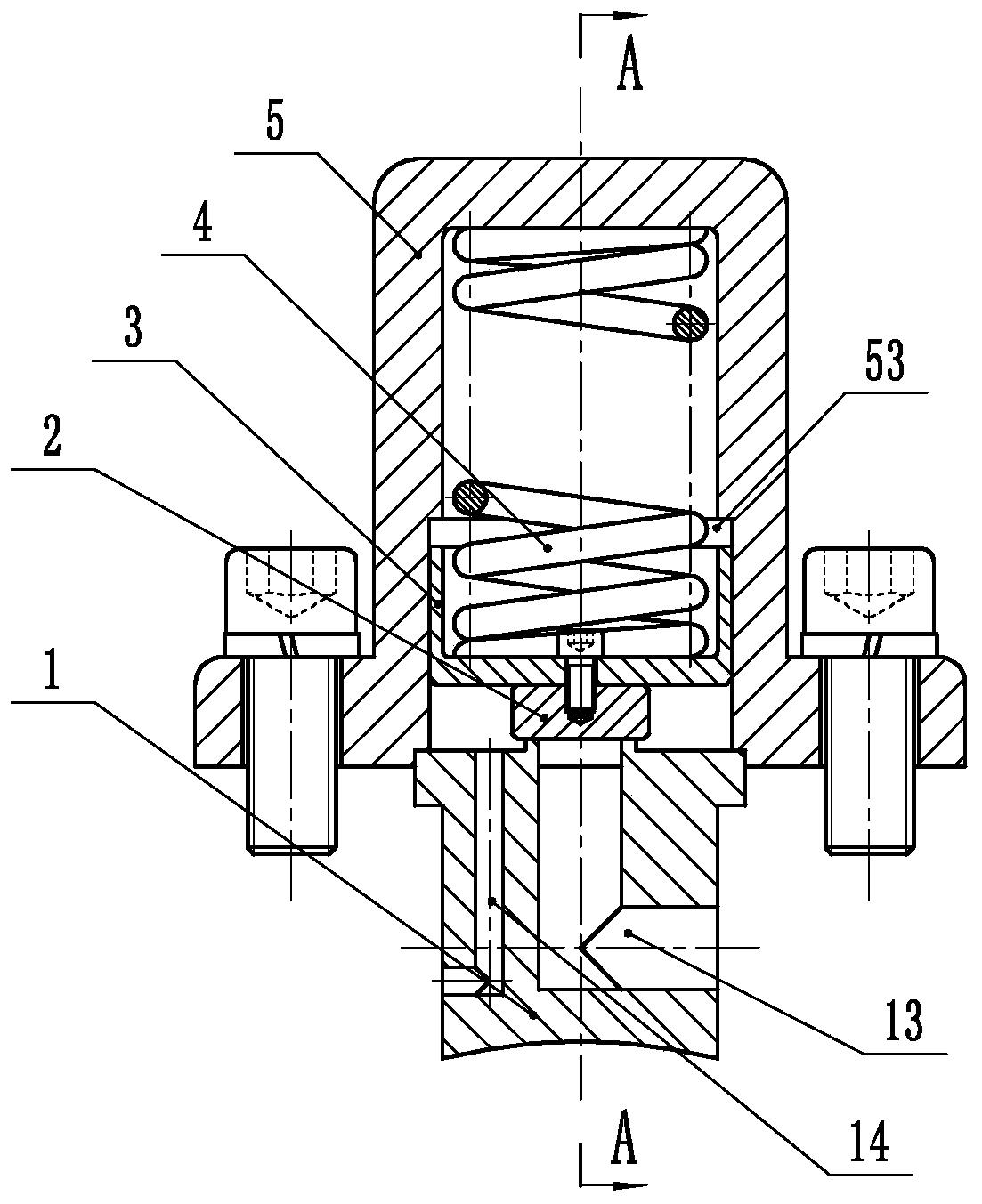

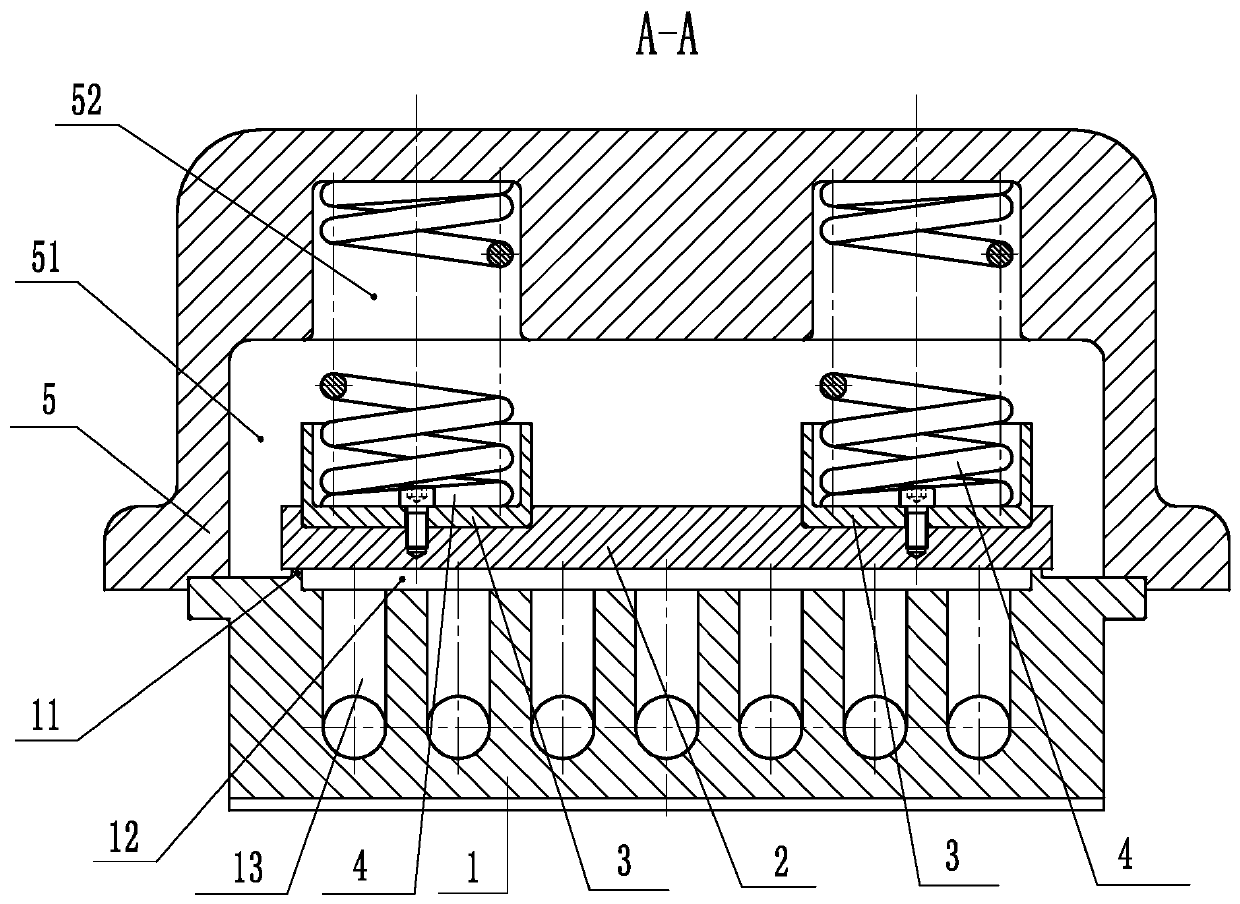

[0021] combine Figure 1 to Figure 3 As shown, the safety valve shown in this embodiment mainly includes a valve body 5, a valve seat 1, and a valve plate assembly, wherein:

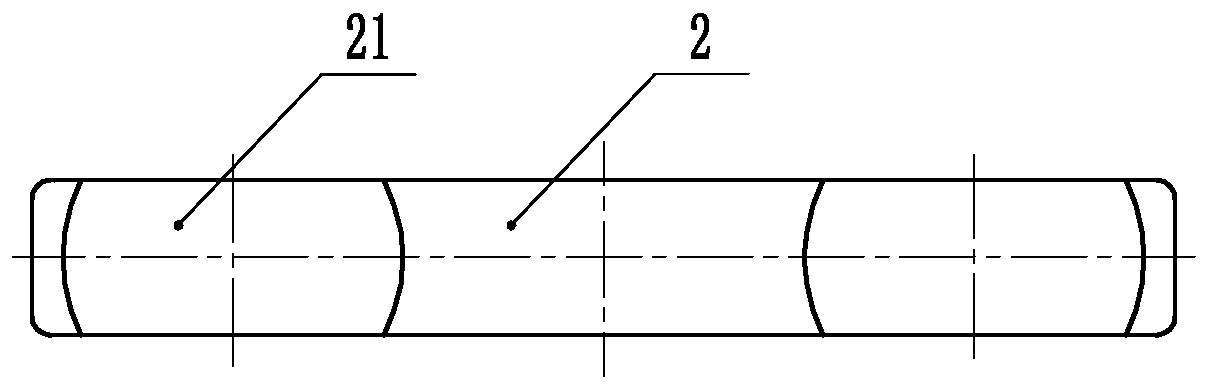

[0022] The valve body 5 is set on the valve seat 1 with the opening facing downwards, and has an open inner chamber, in which there is a rectangular chamber 51 and two cylindrical chambers 52 to match the flat key valve in the valve plate assembly. Plate 2 and double spring, double valve sleeve structure. In addition, two circular grooves 53 are provided in the inner cavity, which are used for guiding and limiting the double valve sleeve 3 .

[0023] The valve seat 1 is airtightly combined with the mouth of the valve body 5, and a raised flat key-shaped step 11 is provided on the upper surface facing the inner cavity of the valve body 5, and a groove is formed after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com