Floating type seal mouse cage valve

A floating, squirrel-cage technology, which is applied in the direction of lifting valves, valve details, valve devices, etc., can solve the problems of large damage to the sealing sheet, deterioration of the working environment of the valve, and high flow rate of the medium, and achieve a good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

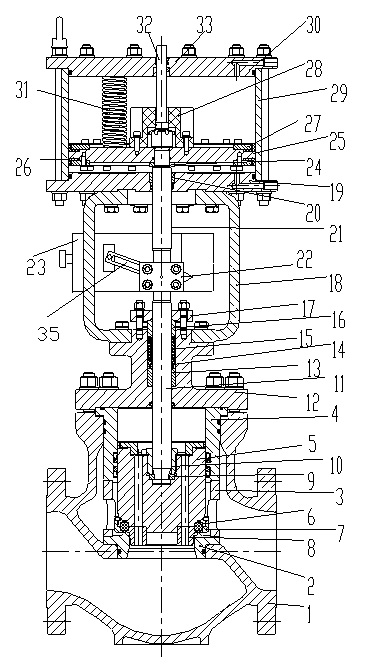

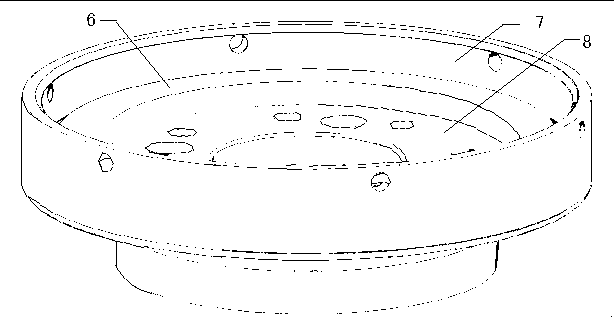

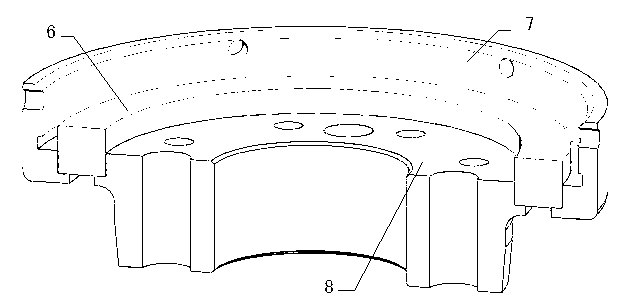

[0025] As shown in the figure, a floating sealed squirrel cage valve includes a valve body 1, a bonnet 12 connected to the valve body, a support frame 18 whose lower end is connected to the bonnet 12, and a sealing seat 2 inside the valve body. The internal balance cylinder 4, the valve core 5 in the inner hole of the balance cylinder 4, the lower valve stem 11 connected with the valve core 5, and the upper valve stem 21 connected with the upper end of the lower valve stem, the valve body is provided with a sleeve 3. The sleeve 3 is under the balance cylinder 4 and above the seal seat 2. The upper end of the sleeve 3 is pressed by the balance cylinder 4, and the lower end of the sleeve presses the seal seat 2. The sleeve is provided with a flow channel hole and a support frame 18 A valve positioner 23 is provided on the valve positioner 23, and a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com