Expansion valve

A technology of expansion valve and valve body, applied in the field of expansion valve, can solve the problems of rising price of expansion valve and supporting facilities, large loss of medium flow energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

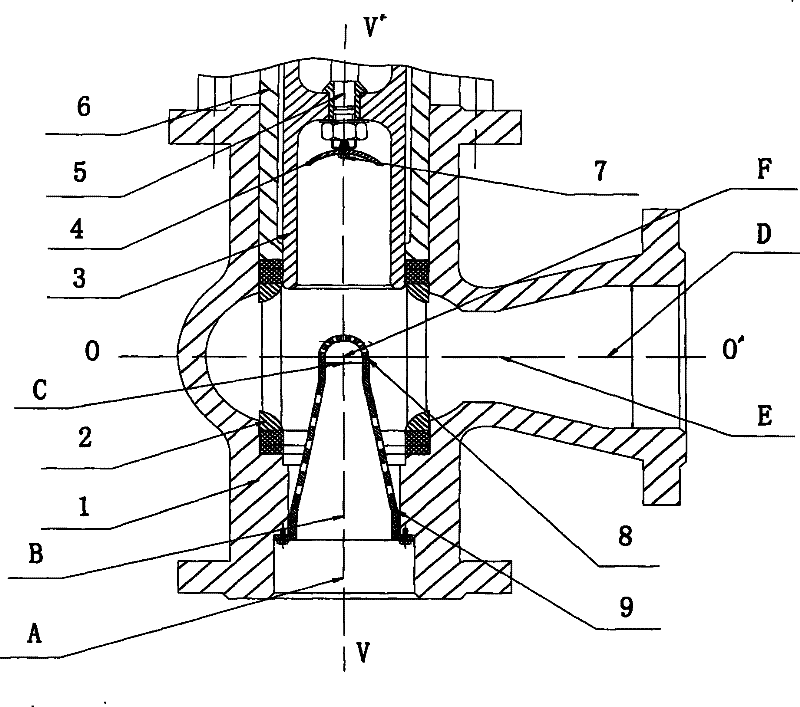

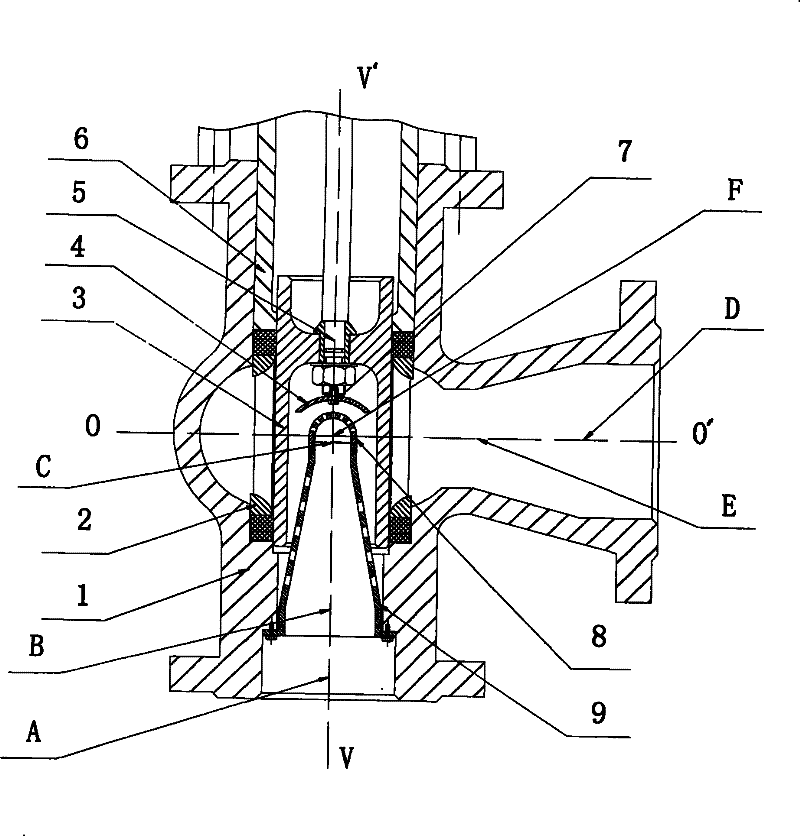

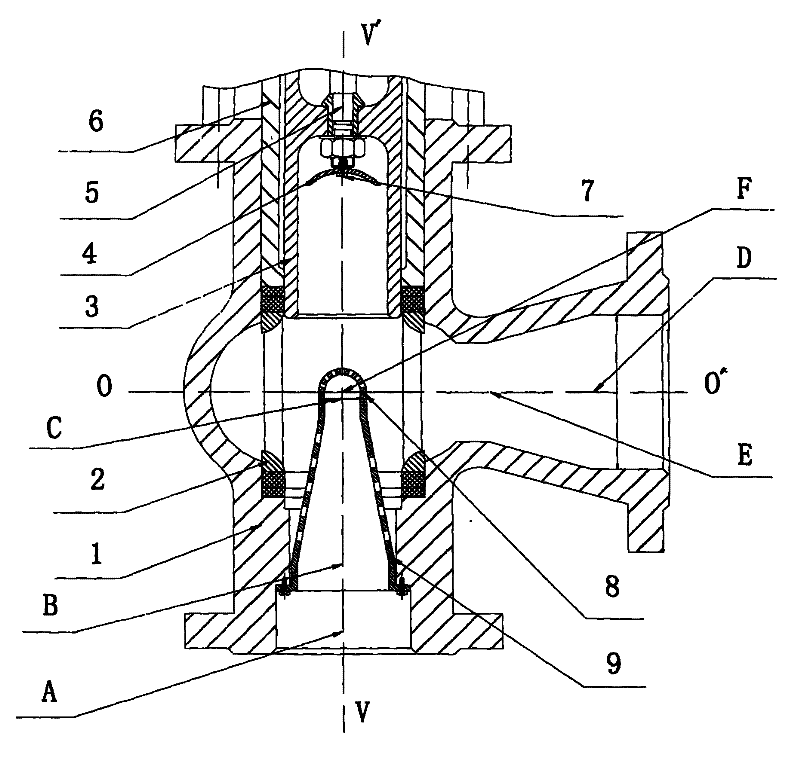

[0009] Such as figure 1 , 2 As shown, the expansion valve includes a valve body 1, which is characterized in that it also includes: the inner cavity of the valve body 1 is provided with a combined sealing ring 2 and a plunger 3 for controlling the flow of the medium, and the combined sealing The upper part of the ring 2 is provided with a bonnet 6 for its positioning, the bonnet 6 is fixedly installed on the valve body 1, the valve stem assembly 5 is installed on the plunger 3, the lower part of the valve stem assembly 5 is provided with a condensation baffle 4, and the valve body A conical cut-off screen 9 is provided at the medium inlet A of the lower part of 1, and a hemispherical steam screen 8 is installed on the upper end of the conical cut-off screen 9 .

[0010] The condensing baffle 4 is fixed on the lower end of the valve rod assembly 5 by screws 7; the lower end of the conical intercepting screen 9 is connected with the valve body 1 by screws, and the conical inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com