High-temperature hexagonal hole wear-resisting ball valve

A hexagonal hole, wear-resistant ball technology, applied in valve details, valve device, valve shell structure and other directions, can solve the problems of shortened valve service life, very serious ball scouring, ball damage, etc., to reduce the medium flow rate, reduce the daily Maintenance cost, impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation of this embodiment will be described below in conjunction with the accompanying drawings.

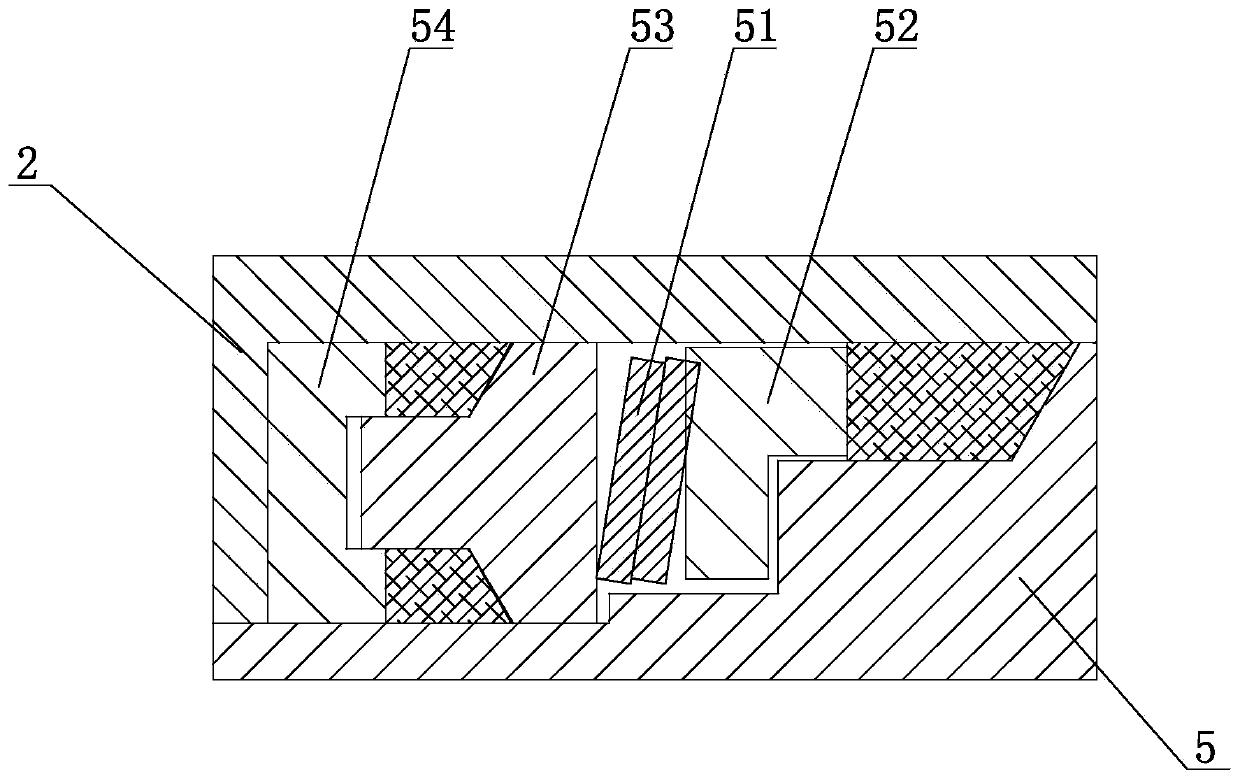

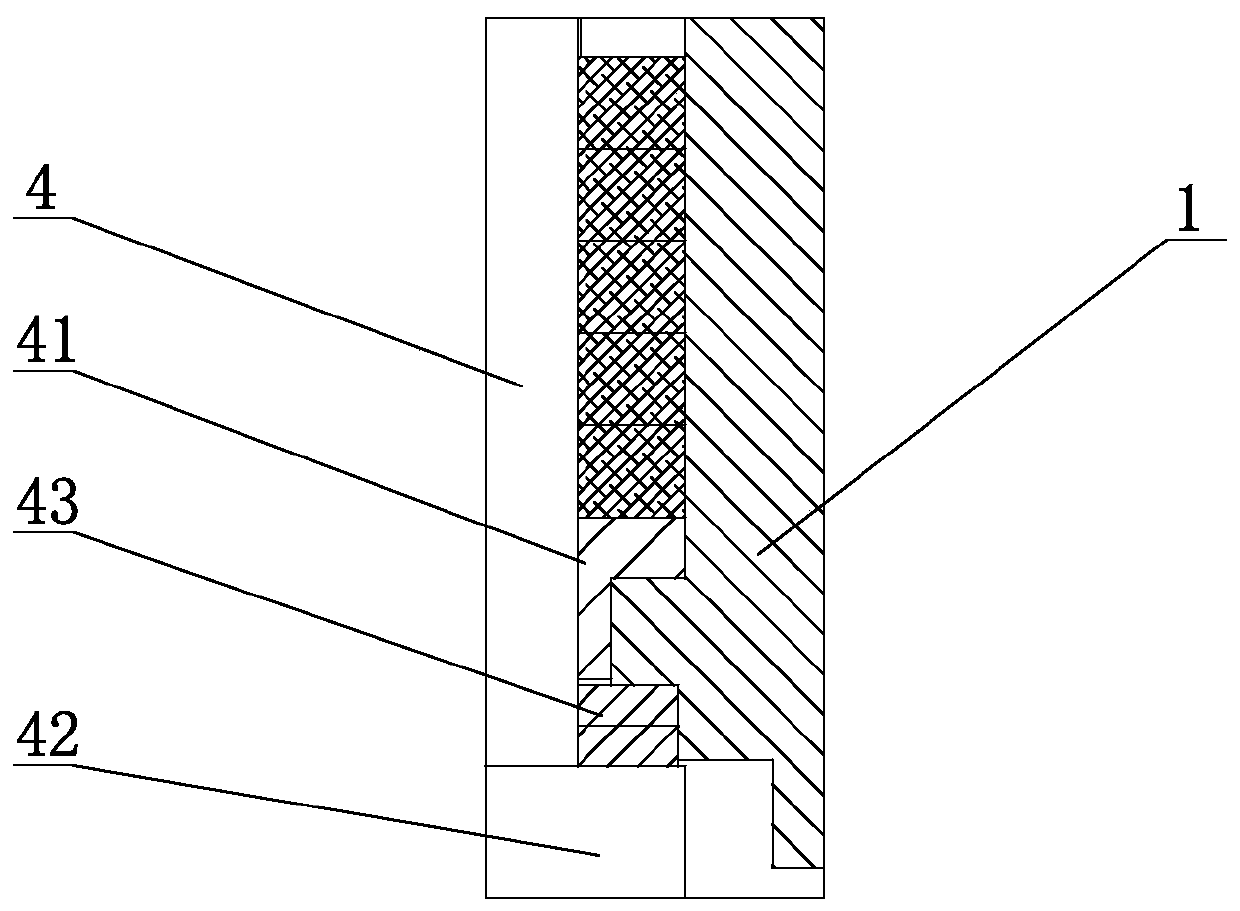

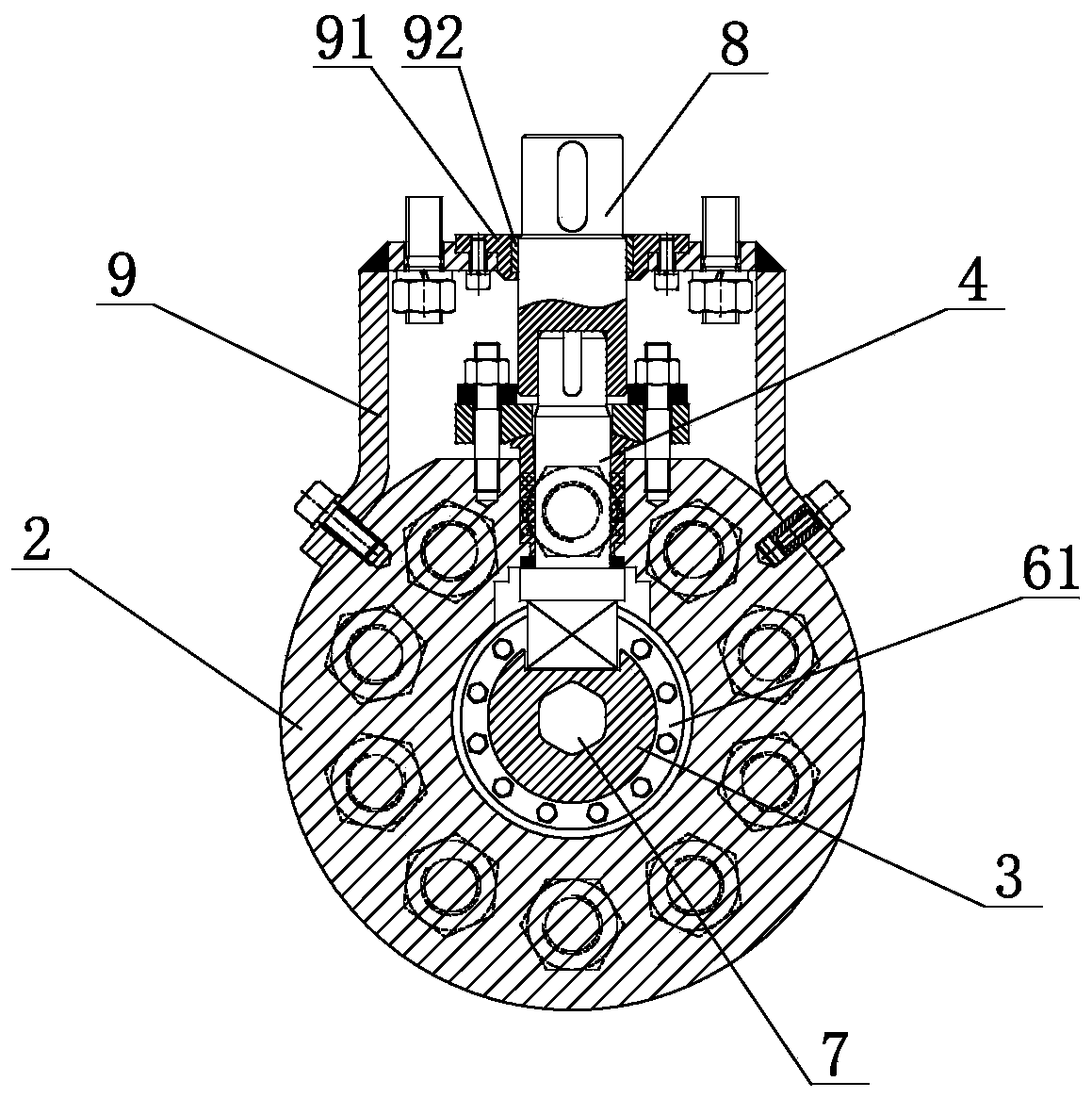

[0023] Such as Figure 1 to Figure 5 As shown, the high-temperature hexagonal hole wear-resistant ball valve of this embodiment includes a valve body 1, a valve cover 2, a ball 3 and a valve stem 4, the ball 3 is arranged in the inner cavity 11 of the valve body 1, and the valve cover 2 passes through the stud nut It is fixed on the front side of the inner cavity 11 of the valve body 1, and a C-shaped ring 21 and a wound gasket 22 for sealing are also provided between the valve cover 2 and the valve body 1. The valve stem 4 is connected to the upper end of the ball 3, and the inner cavity 11 is located on the ball 3 The front and rear sides are provided with the front valve seat 5 and the rear valve seat 6, and the rear valve seat 6 is pressed and fixed in the valve body 1 by the valve seat pressure ring 61, and the back of the rear valve seat 6 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com