Forged isolation type vacuum starting valve

An isolation type, start-up valve technology, used in control valves, lift valves, valve details, etc., can solve problems such as false closing, unstable flow, valve damage, etc., to ensure sealing, eliminate customs clearance problems, and slow down the effect of the medium flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings, and embodiments of the present invention will be given.

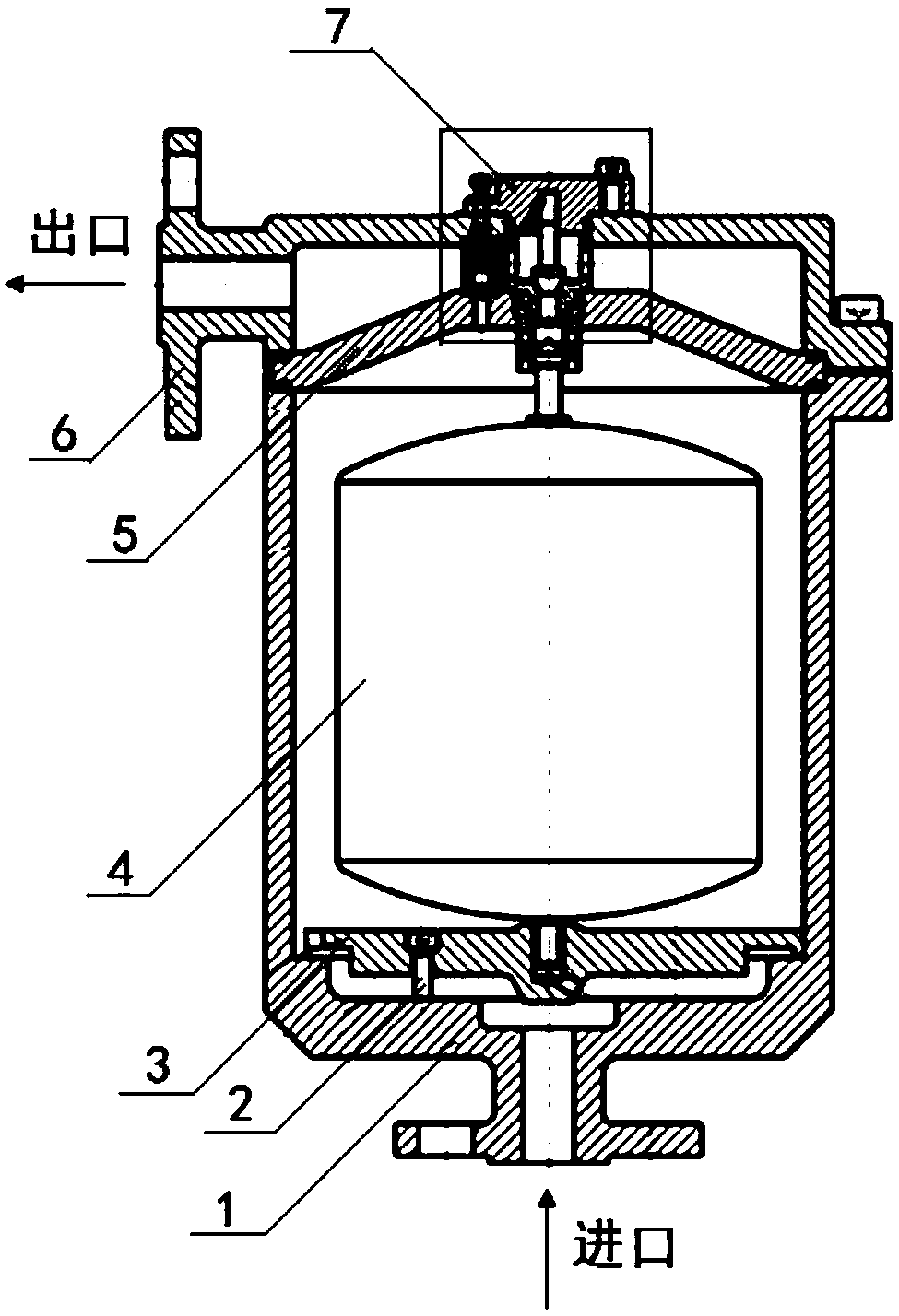

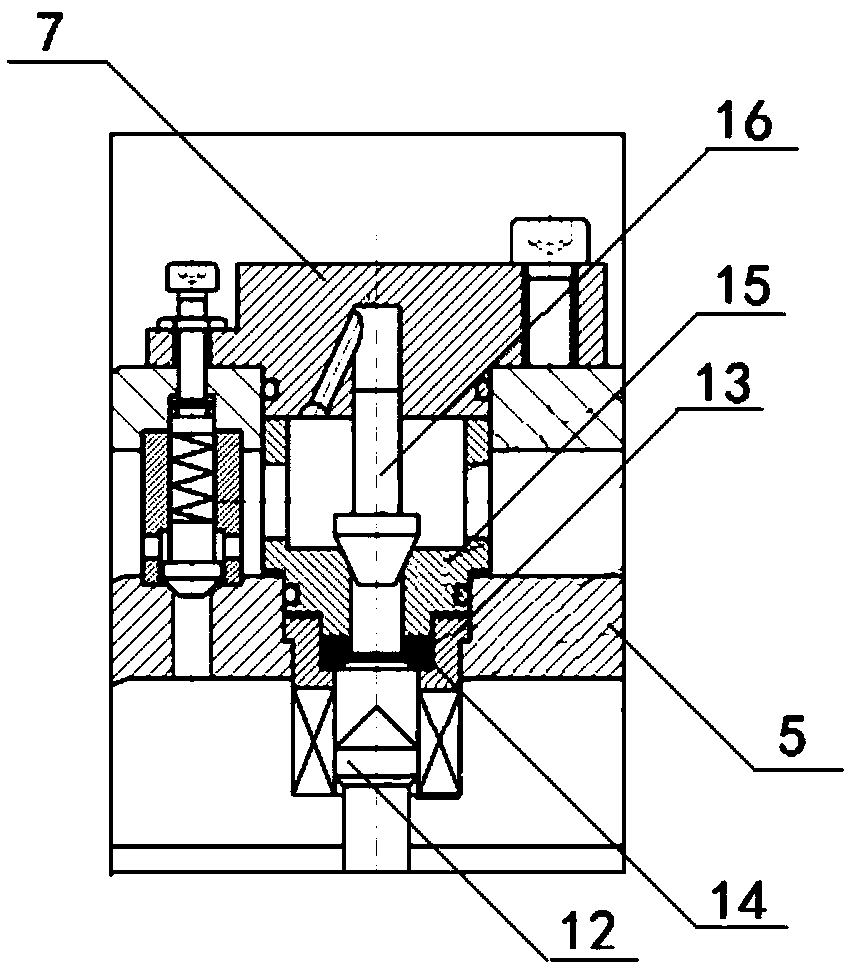

[0028] Such as figure 1 The isolated vacuum starting valve shown includes a valve body 1, a valve cover 6, an end cover 7, a buoy 4, and a valve seat. The body cavity is divided into an upper valve cavity A and a lower valve cavity B. The buoy 4 is placed in the lower valve cavity B directly connected with the water inlet, and the valve seat on the upper part of the buoy 4 is formed with the partition 5 and the water outlet. The connected valve body closing or opening mechanism; characterized in that:

[0029] The bottom of the lower valve cavity B in the water inlet of the valve body 1 is provided with an anti-scour structure to prevent the water flow from directly impacting the buoy;

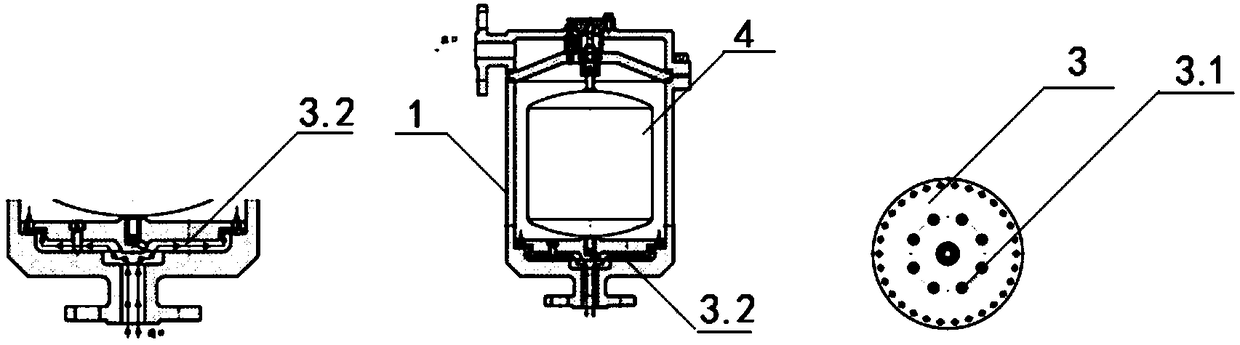

[0030] figure 2 The setting position and structural diagram of the anti-shock plate 3 in the valve body are given. The anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com