Light field camera internal parameter calibration device and method

A technology of light field camera and calibration device, which is applied in image data processing, instrumentation, calculation, etc., can solve the problems of redundant decoding matrix parameters and inapplicability of microlenses, etc., to achieve good flexibility, improve calibration accuracy, and solve decoding problems. Effects of Matrix Parameter Redundancy Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the drawings and embodiments. The present invention includes but is not limited to the following embodiments.

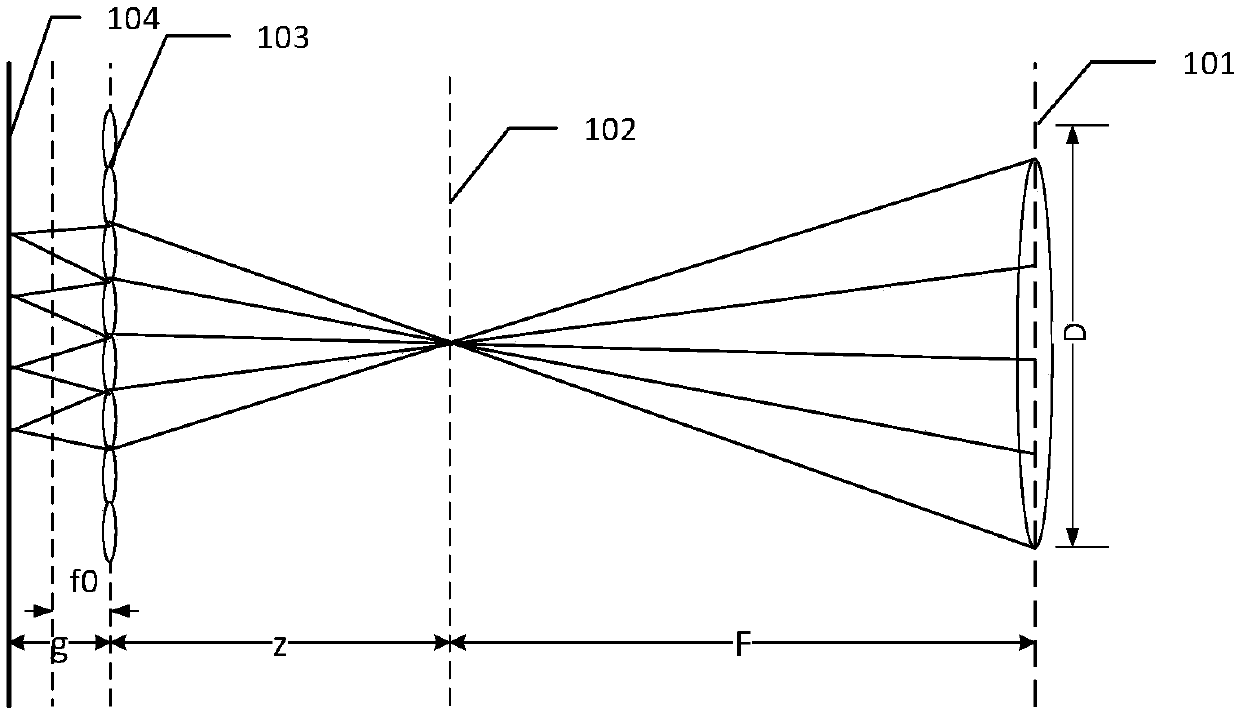

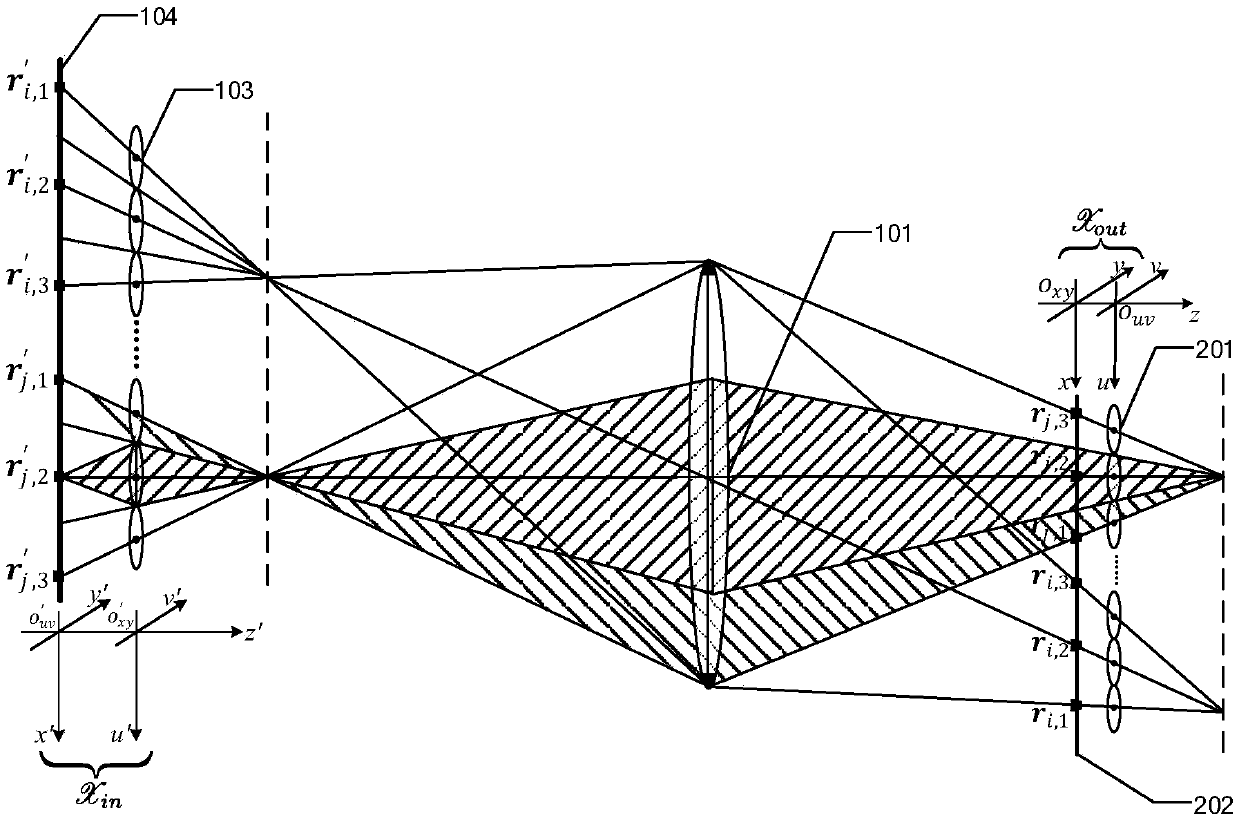

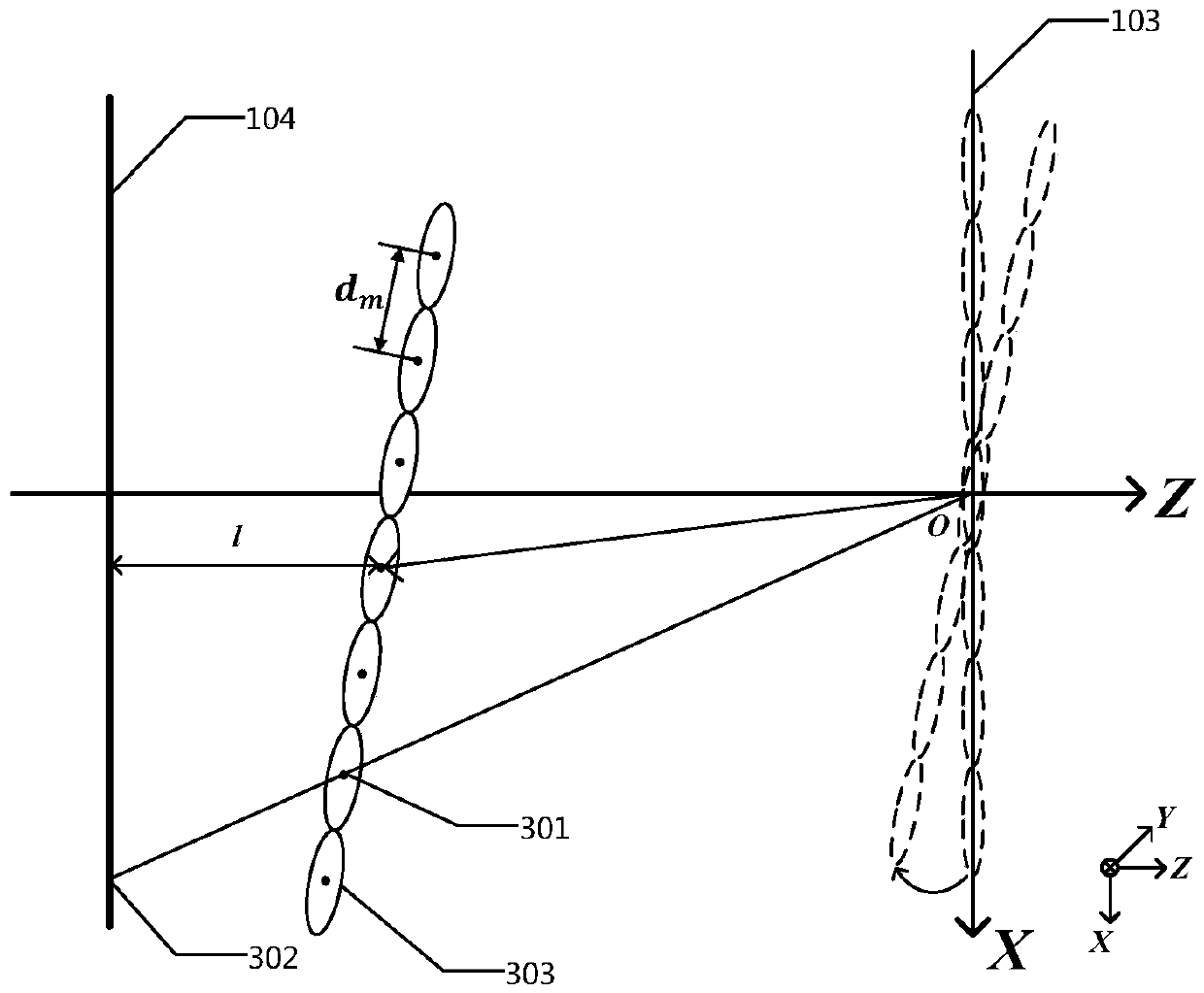

[0017] In one aspect of the present invention, a device for calibrating parameters in a light field camera is provided, which includes: a light field camera, a calibration board, an electronically controlled translation stage, a motion controller, and an angle rotation stage. Place the calibration board at a certain distance in front of the main lens of the light field camera, and fix it on the angle rotating table, where the calibration board and the computer terminal are connected through a serial port and the terminal controls the calibration board to rotate at different angles , Used to shoot calibration boards in different postures. Fix the light field camera on the electronically controlled translation stage. Among them, one end of the motion controller is connected to the computer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com