Oblique pole method of permanent-magnet motor rotor

A technology for permanent magnet motors and rotors, which is applied in the direction of magnetic circuit rotating parts, magnetic circuits, electrical components, etc., and can solve problems such as the adverse effects of cogging torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is further described in detail through specific implementation methods:

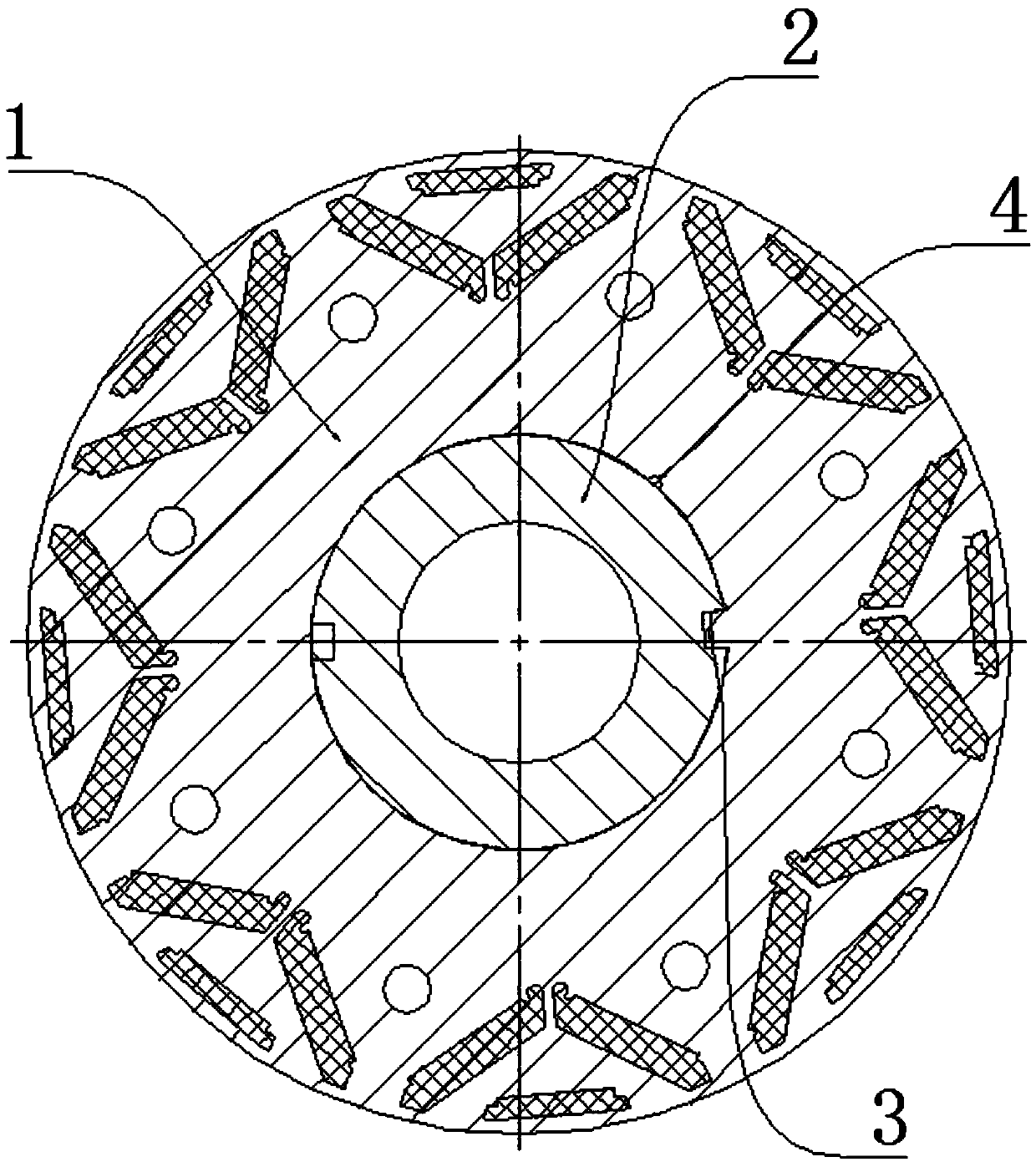

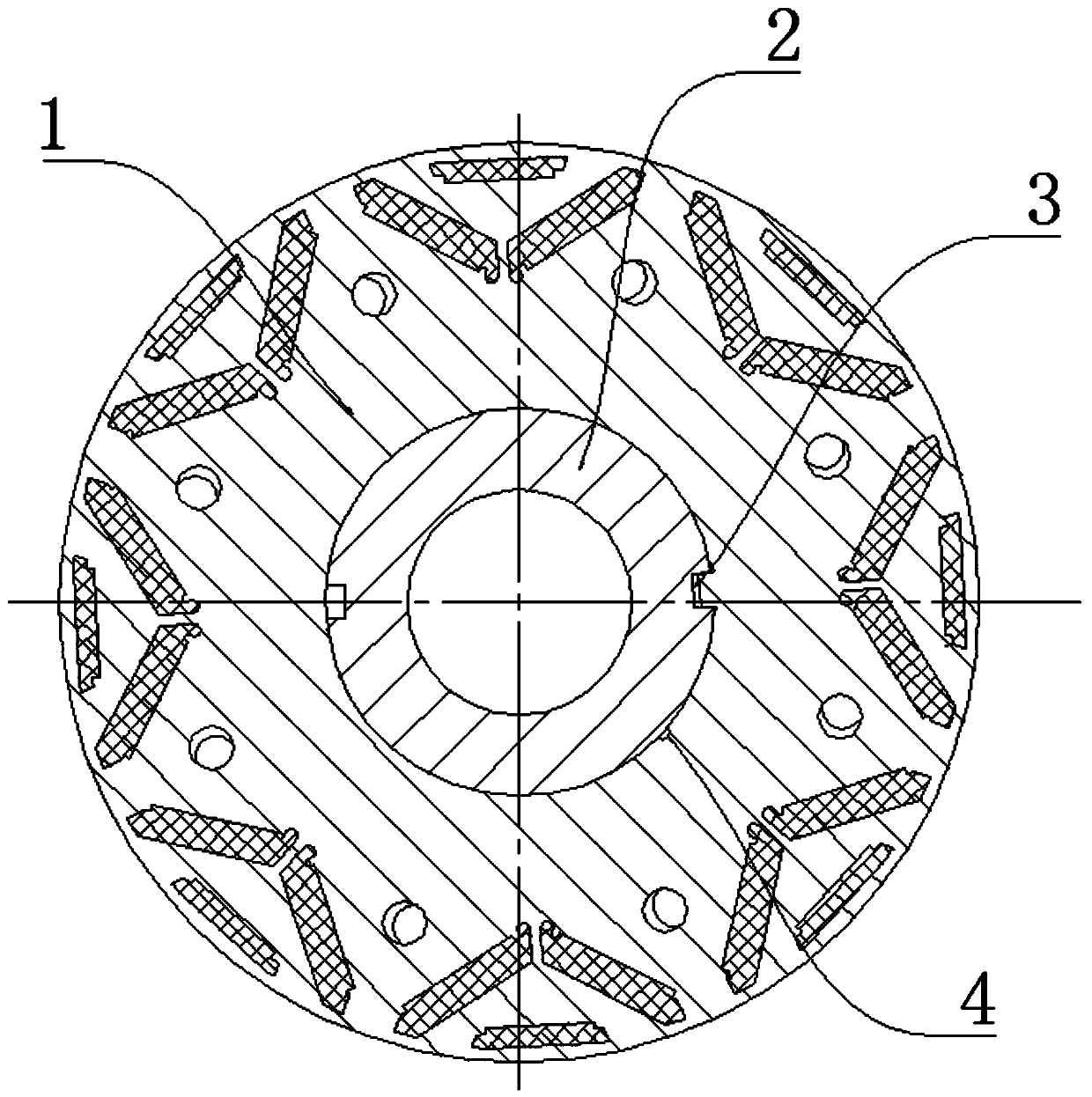

[0026] The reference signs in the drawings of the specification include: rotor core 1 , rotating shaft 2 , key groove 3 , and symbol groove 4 .

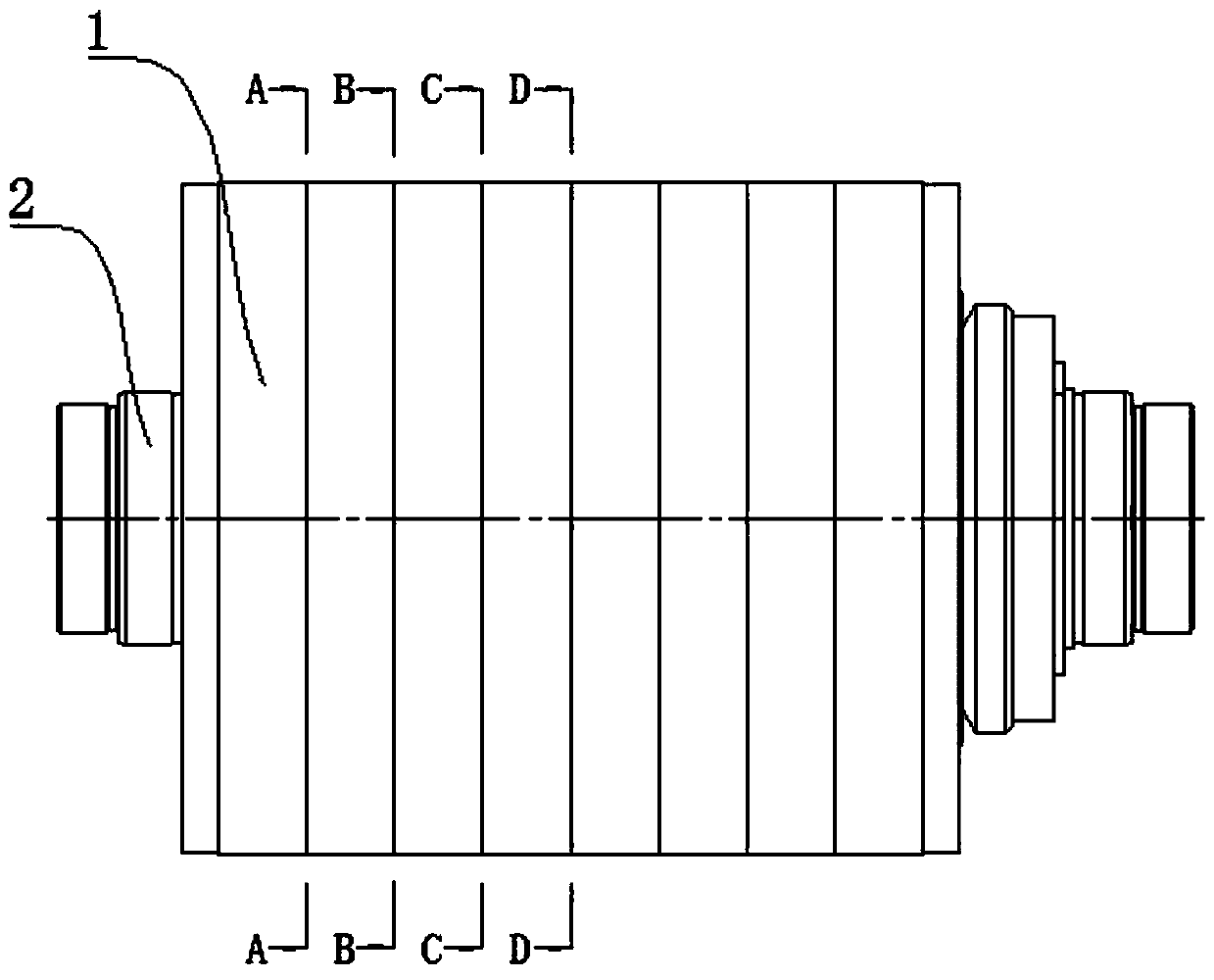

[0027] The embodiment is basically as attached figure 1 Shown: The permanent magnet motor rotor skew method, including the following steps:

[0028] A. Machining two asymmetric key grooves 3 on the rotating shaft 2 of the rotor;

[0029] B. Use rotor punches to form eight sections of rotor core 1, and each section of rotor core 1 is cylindrical. Select every two sections of rotor core 1 as a pair, and select two pairs of rotor cores 1 as a group. The marking groove 4 is processed at the same position on the inner wall of the shaft hole of each rotor core 1, and the marking groove 4 is a semicircular groove;

[0030] C. Install two groups of rotor cores 1 symmetrically on the rotating shaft 2, and install the two rotor cores 1 of each pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com