Rib punching die

A mold and bead punching technology, which is applied in the field of molds, can solve the problems of high processing cost and low efficiency of bead punching on the surface of cup tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

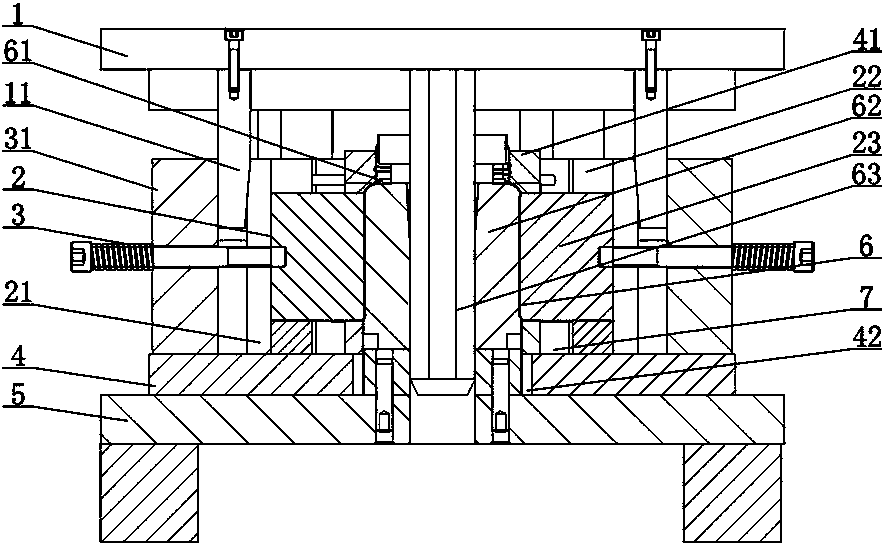

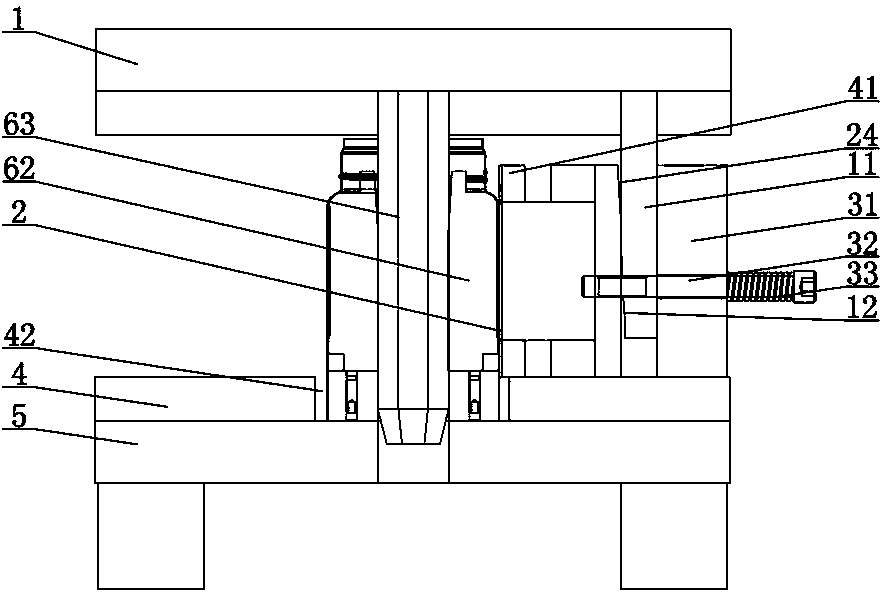

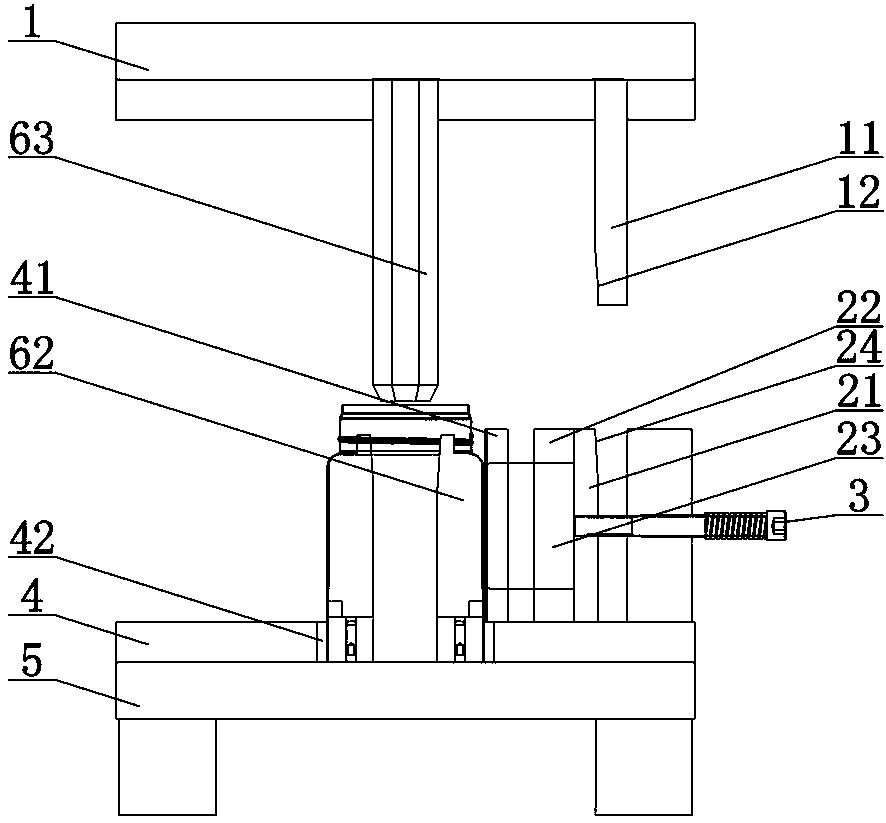

[0032] A bead punching die, comprising an upper mold base 1, a lower mold base 5, a punch assembly 2, a punch table 4, a support assembly 6, and a punch reset assembly 3, and the punch table 4 is arranged on the lower mold base 5, the punch table 4 is provided with a housing chamber 42, the punch assembly 2 surrounds the housing chamber 42 in an annular array, the support assembly 6 is arranged inside the housing chamber 42, and the punch resets The assembly 3 is connected to the punch assembly 2 and provides an outward restoring force for the punch assembly 2. The upper die base 1 is provided with a side insertion knife 11. When the upper die base 1 moves downward , the side inserting knife 11 moves down and drives the punch assembly 2 to move inward, and when the upper die base 1 moves upward, the punch assembly 2 moves downward driven by the punch reset assembly 3 Move outside.

[0033] When in use, the cup tube is placed in the accommodating cavity 42, the upper die base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com