Container leveling conveying system used in large logistics warehouse

A technology of conveying system and container, which is applied in the field of logistics warehouse conveying system, can solve the problems of low work efficiency and low degree of intelligence, and achieve the effect of saving manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

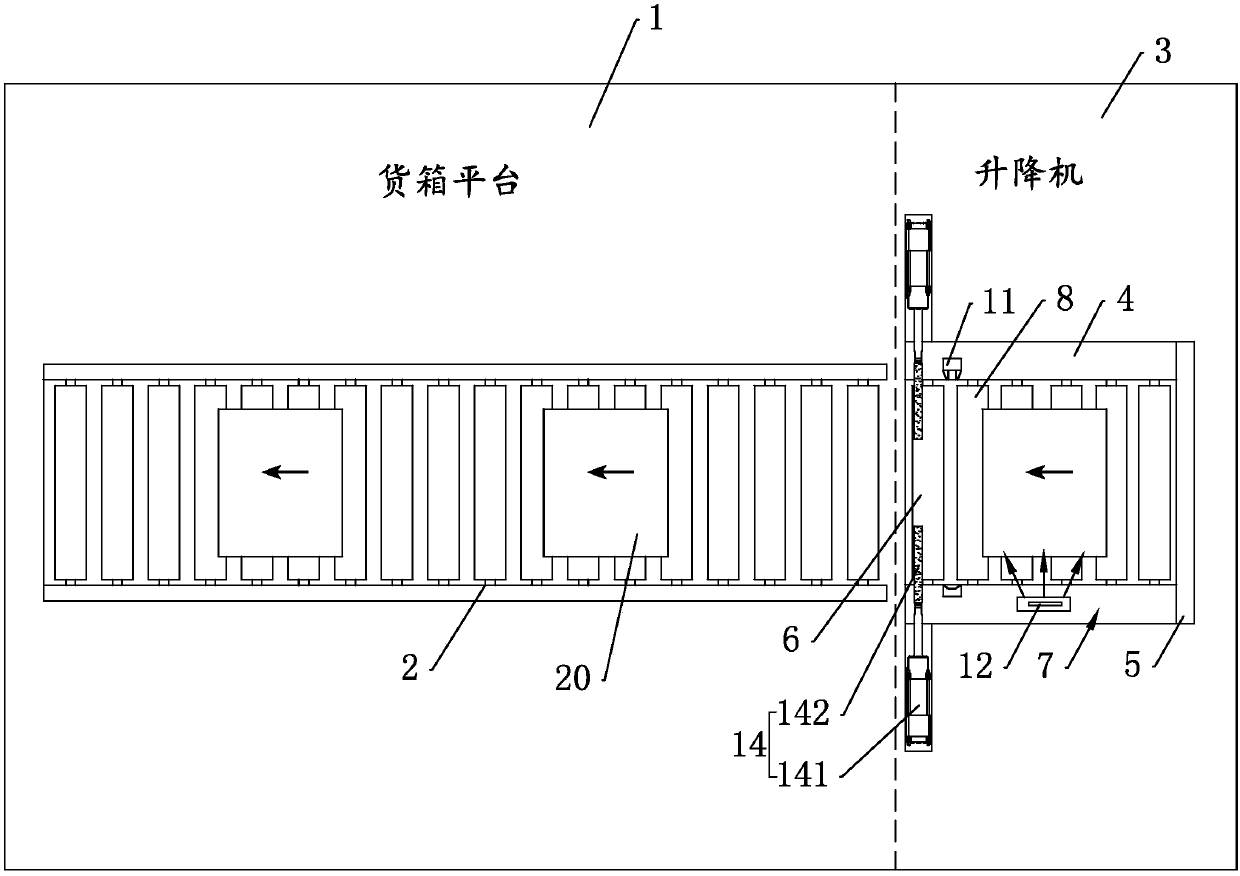

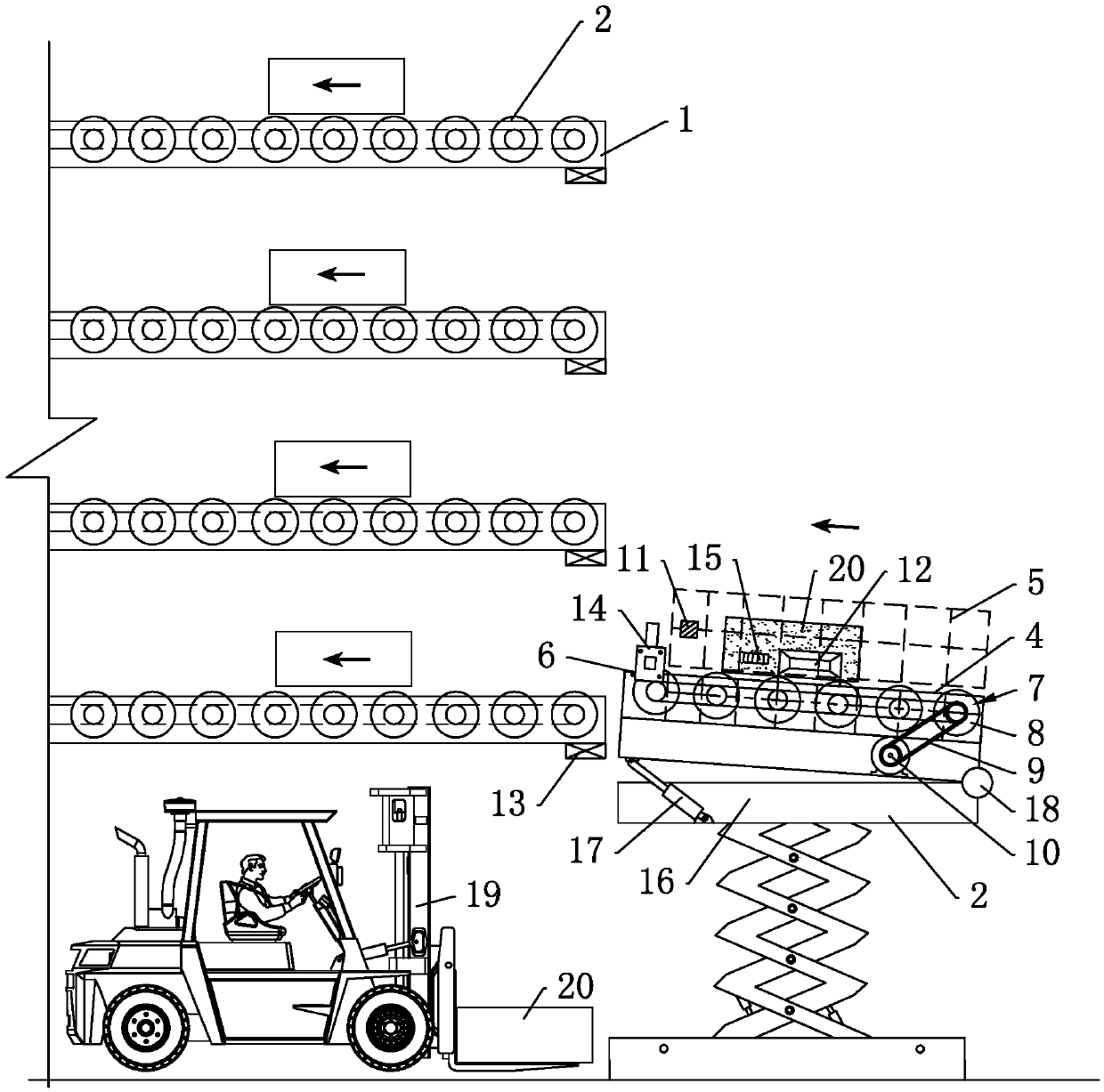

[0023] refer to figure 1 and figure 2 , which is a layered conveying system for cargo boxes in a large-scale logistics warehouse disclosed in the present invention, comprising a multi-layer cargo box platform 1 arranged in a vertical direction in the warehouse, and a conveyor belt arranged on each layer of the cargo box platform 1 2. The elevator device installed on the ground and the label identification device located in the elevator device. The staff drives the forklift 19 to insert the container 20 into the elevator device. The label 15 is identified. After the identification is completed, the pre-stored information in the label and the information of the corresponding container platform 1 are recorded. The lifting and lowering container 20 on the elevator device is transported to the corresponding container platform 1. The container 20 transported from the elevator device can be received and then transferred to the corresponding container placement rack.

[0024] More ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com