Multifunctional aviation engine air inlet channel and running method thereof

A technology of aero-engine and operating method, which is applied in the direction of engine components, machine/engine, turbine/propulsion device air intake, etc., can solve the problems of aero-engine safe operation, inability to guarantee foreign object intrusion, air crash accidents, etc., to achieve The Effects of Premium Radar and Infrared Stealth Capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

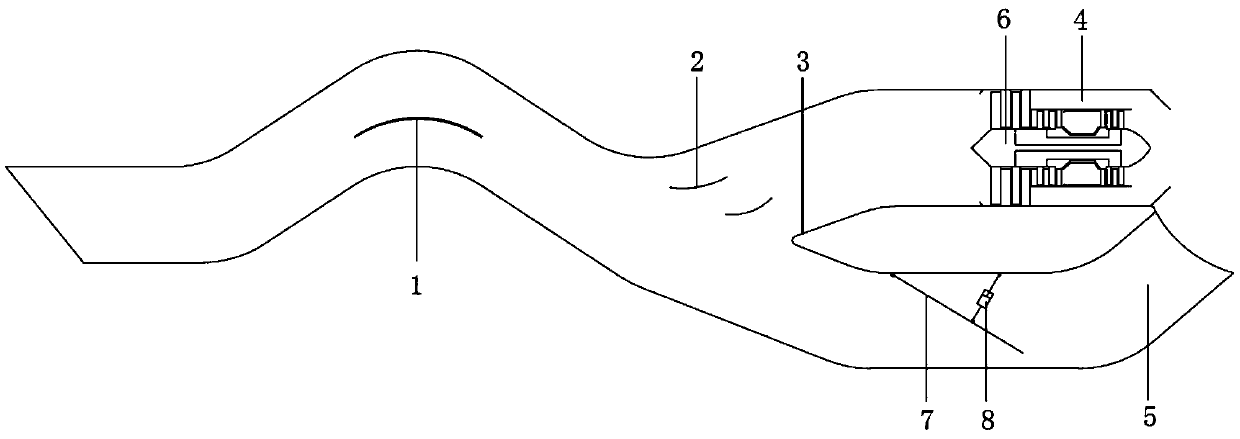

[0016] like figure 1 As shown, a multifunctional aero-engine air intake includes a rectifying wall 1 with the function of measuring momentum energy, a rectifying wall 2 in front of the engine air intake, a fish mouth type diverter ring 3, an engine mounting channel 4 and a foreign object injection channel 5. The rectifying wall 1 with the function of measuring momentum energy passes through the rectifying wall 2 before the engine intake, the fish mouth type diverter ring 3 and the engine installation flow channel 4, and the rectifying wall 1 with the function of measuring momentum energy communicates with the other way The fish mouth type diverter ring 3 is in communication with the foreign matter injection channel 5; the aero-engine 6 is located in the engine installation flow channel 4; a foreign object baffle plate 7 is installed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com