High-low pressure change-over valve and using method thereof

A high-low pressure conversion and valve core technology, applied in valve details, multi-port valves, valve devices, etc., can solve the problem of fluid transportation that cannot be isolated from the high-pressure end and the low-pressure end, achieve ingenious structural design and reduce energy consumption. and noise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: High and low pressure switching valve.

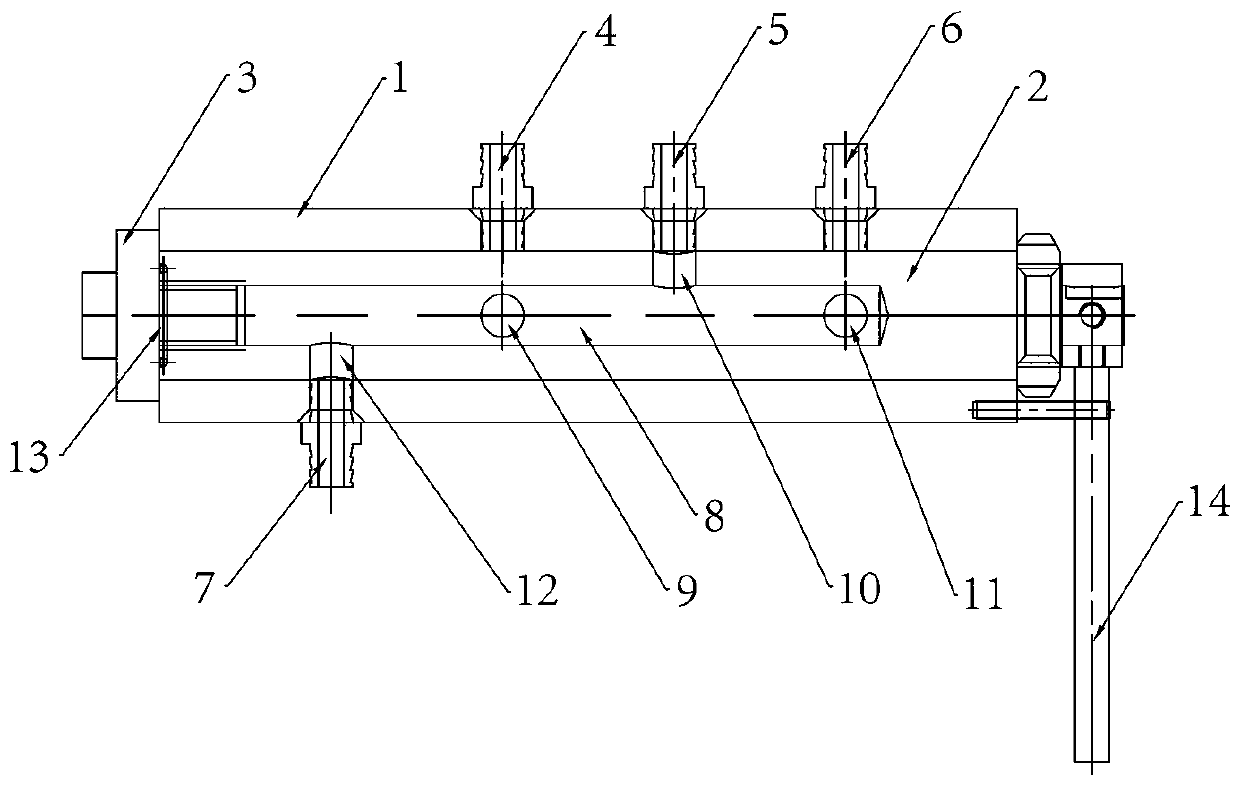

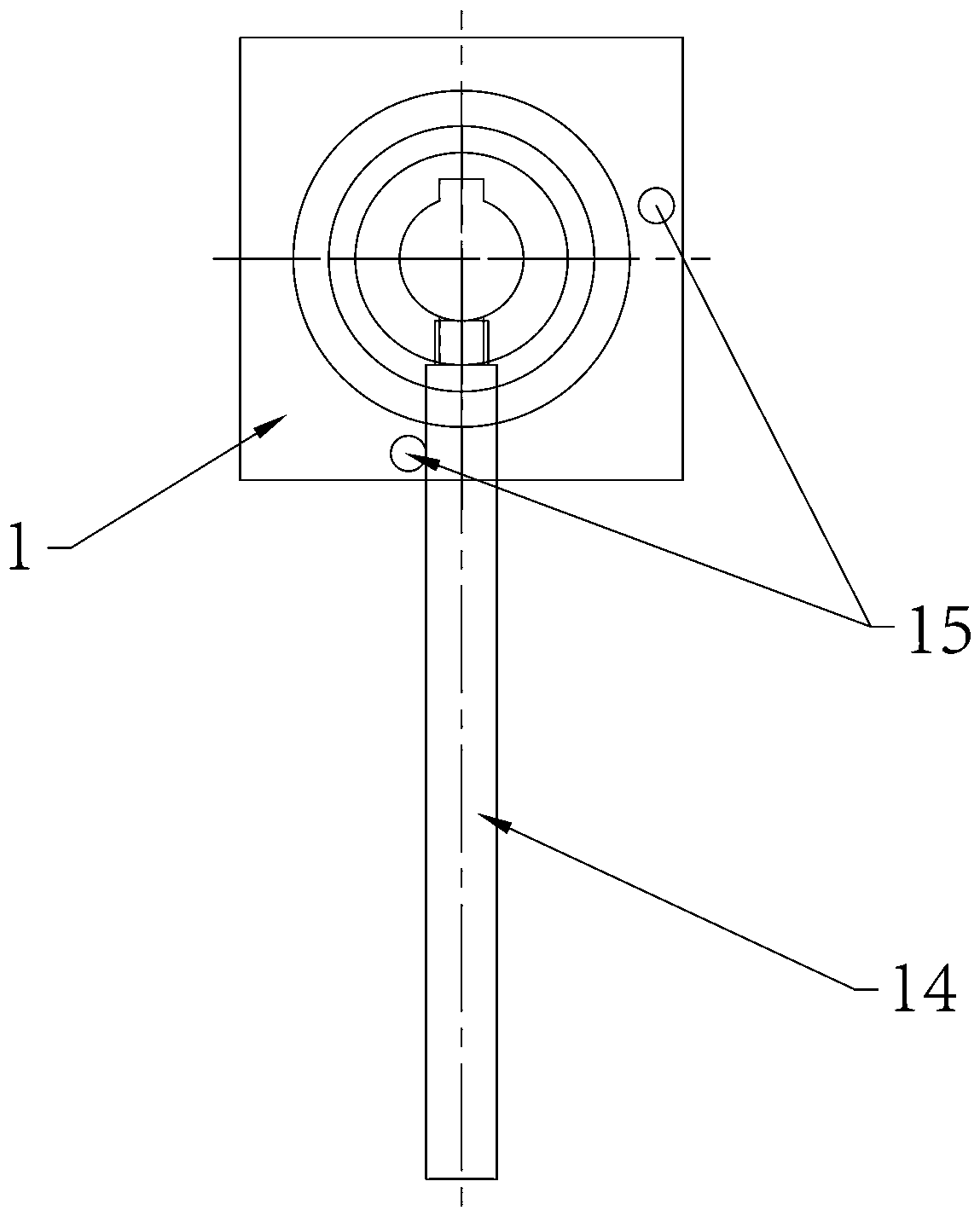

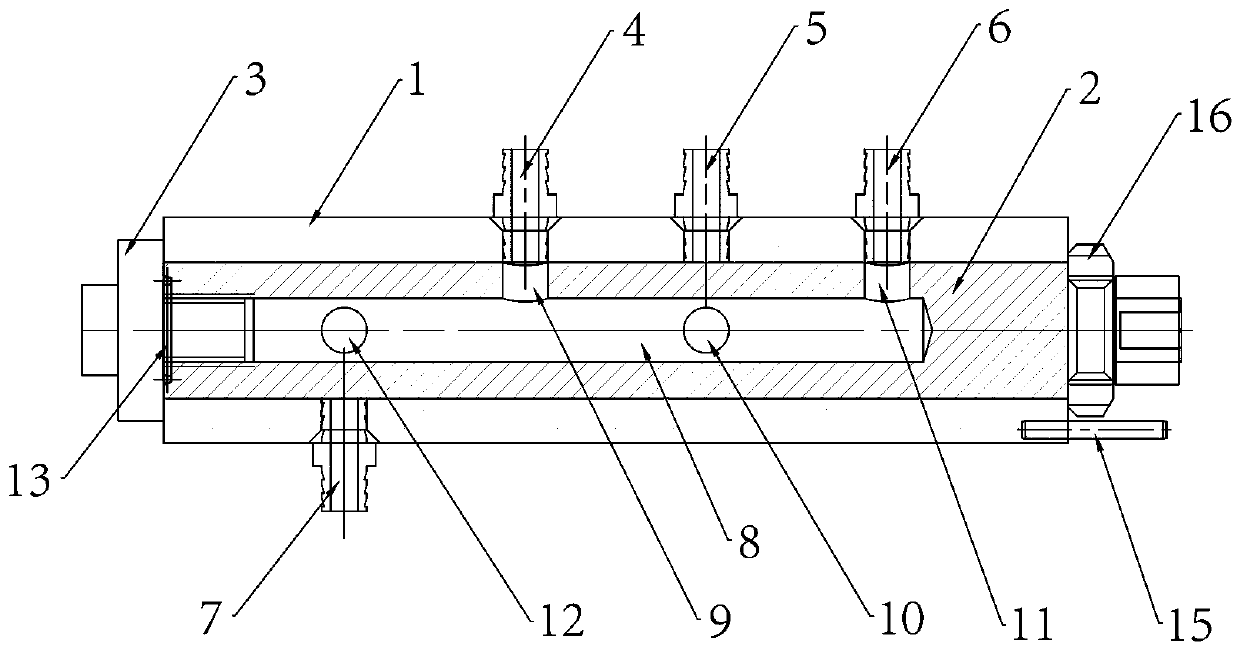

[0019] Such as figure 1 As shown, the present invention mainly includes a housing 1, a valve core 2 disposed in the housing 1, an end plug 3 disposed at one end of the housing 1 to block the valve core, and disposed at the other end of the housing 1 to drive the valve. The core 2 rotates in the casing 1 and other parts such as the lever assembly.

[0020] The housing 1 is in the shape of a square column and has a cylindrical cavity. An end plug 3 is provided at one end of the housing 1, and an air outlet nozzle 4, an air inlet nozzle 5, a liquid inlet nozzle 6 and a liquid outlet nozzle are arranged on the side of the housing 1. Mouth7. The spool 2 is cylindrical and is arranged in the cavity of the casing 1. The spool 2 and the casing 1 are in a rotatable and sealed connection, and the sealing method can be a commonly used mechanical seal. The spool 2 has an axial inner chamber 8, one end of the inner chamber 8 ...

Embodiment 2

[0023] Embodiment 2: The use method of the high and low pressure switching valve.

[0024] The method for using the high and low pressure switching valve of the present invention comprises the following steps:

[0025] 1) Set the high and low pressure switching valve described in Example 1, and connect the liquid inlet nozzle 6 with the fluid outlet of the low pressure end 18 through the first fluid delivery pipe, and the gas outlet nozzle 4 with the gas outlet of the low pressure end 18 through the first connecting pipe Connected, the liquid outlet nozzle 7 is connected to the fluid inlet of the high-pressure end 17 through the second fluid delivery pipe, and the air inlet nozzle 5 is communicated with the gas outlet of the high-pressure end 17 through the second communication pipe, as Figure 4 shown;

[0026] 2) Turn the lever 14 to the low-pressure positioning pin. At this time, the valve core 2 rotates until the air outlet 9 communicates with the air outlet 4, the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com