A system and a method for batch code scanning and station passing of label-free electronic components on a production line

A technology for electronic components and production lines, which is applied in the field of intelligent manufacturing and can solve problems such as long reading time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The invention discloses a method for scanning codes and passing stations of unlabeled electronic components in batches on a production line, which is realized by a system for scanning codes and passing stations of unlabeled electronic components in batches on a production line.

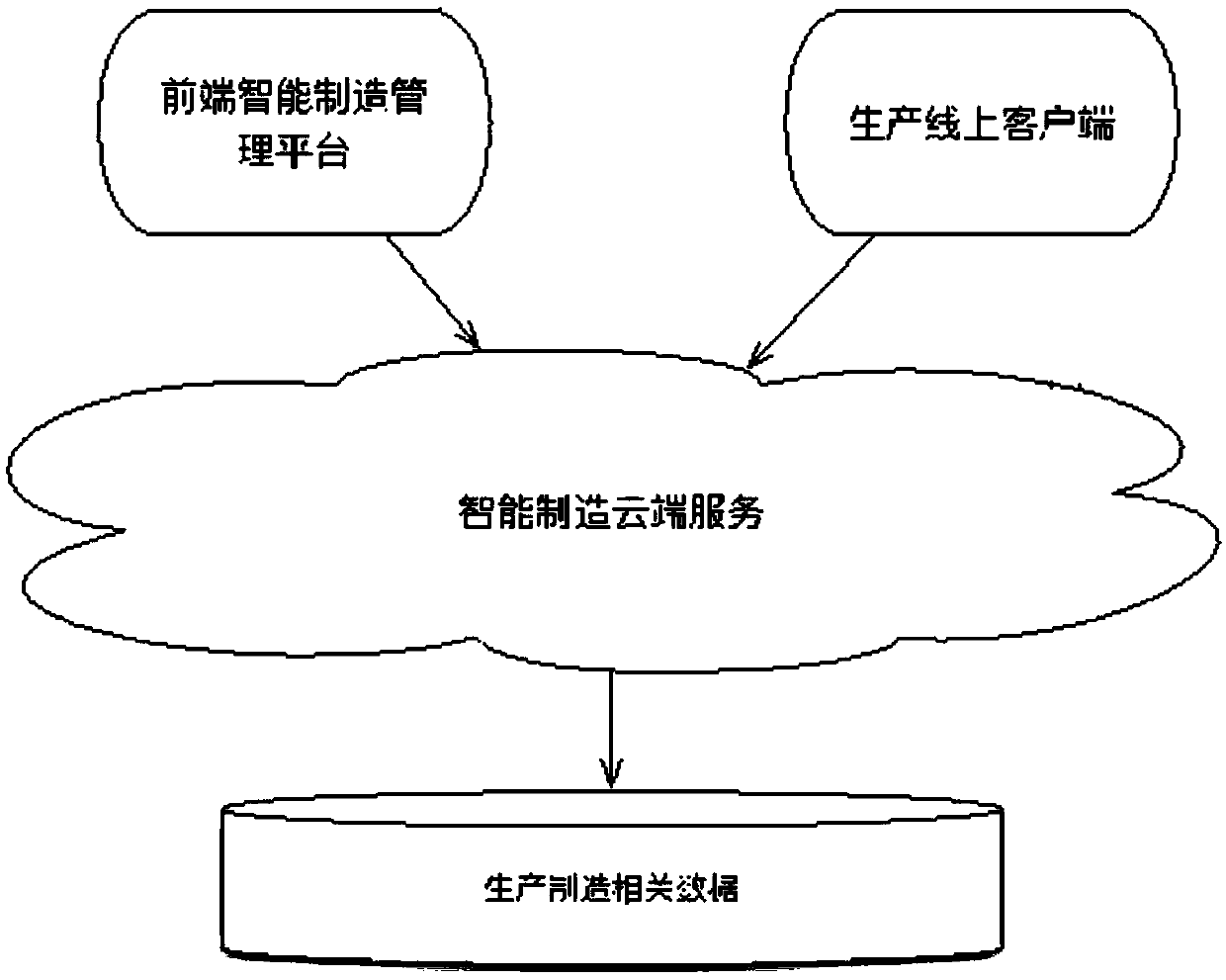

[0035] like figure 1 As shown, the system for unlabeled electronic components on the production line to scan codes and pass stations in batches specifically includes three subsystems: intelligent manufacturing management platform, production line client, and intelligent manufacturing cloud server. Among them, the intelligent manufacturing management platform and production line customers The terminals are respectively connected to the intelligent manufacturing cloud server. The intelligent manufacturing management platform is used to manage the turntable and save various data in production for retrospective query; the client on the production line is used to manage the specific production proces...

Embodiment 2

[0062] A method for scanning codes and passing stations of unlabeled electronic components in batches on a production line, specifically comprising:

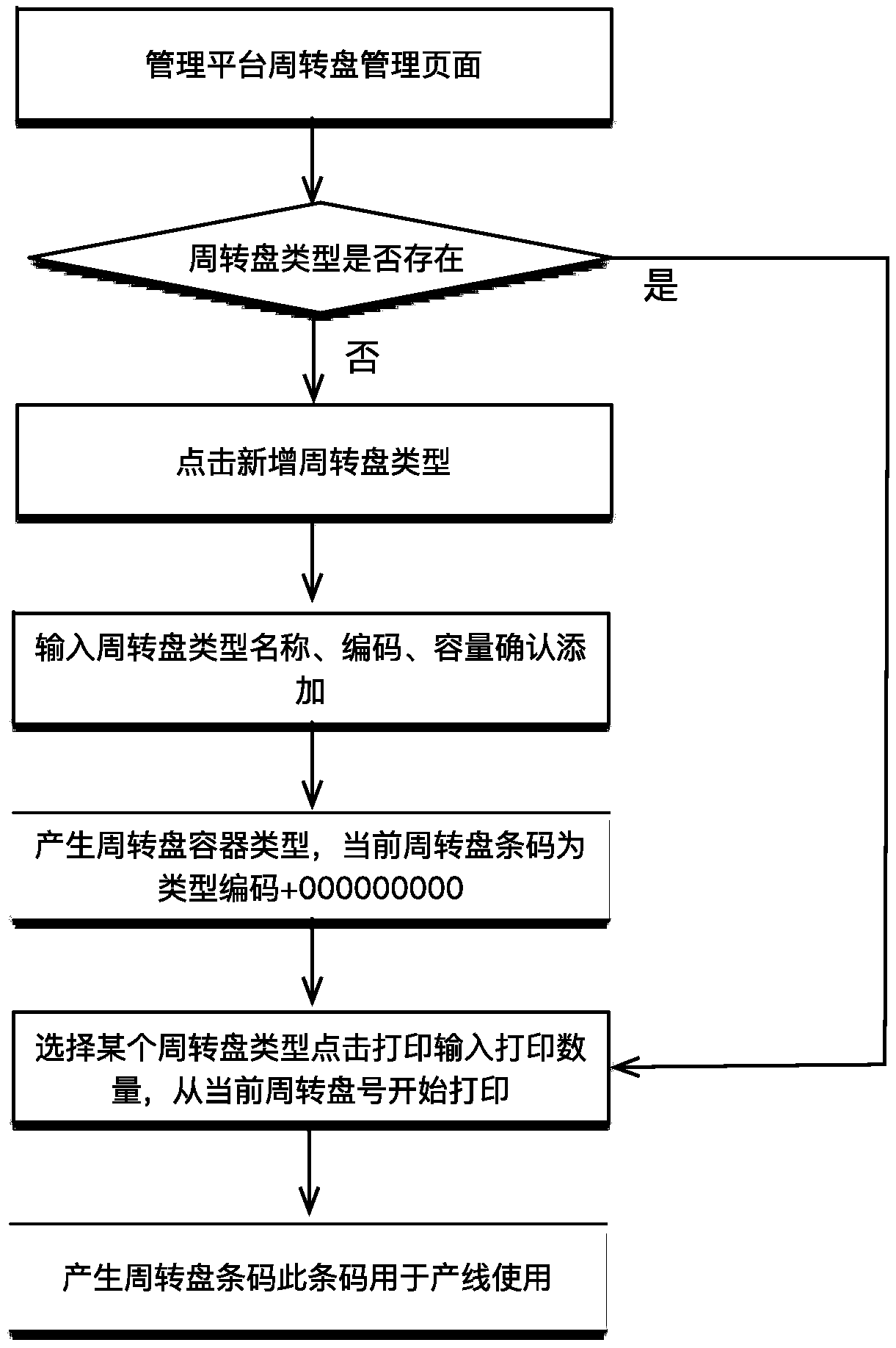

[0063] Step 1: Enter the turntable type management of the client on the production line, add a turntable whose type code is AA, and select this type to print a barcode, the barcode is AA000000000. Paste this barcode on a specific turntable of type AA. Among them, the process of printing the barcode on the turntable is as follows: figure 2 shown.

[0064] Step 2: Bind with the product through the intelligent manufacturing management platform:

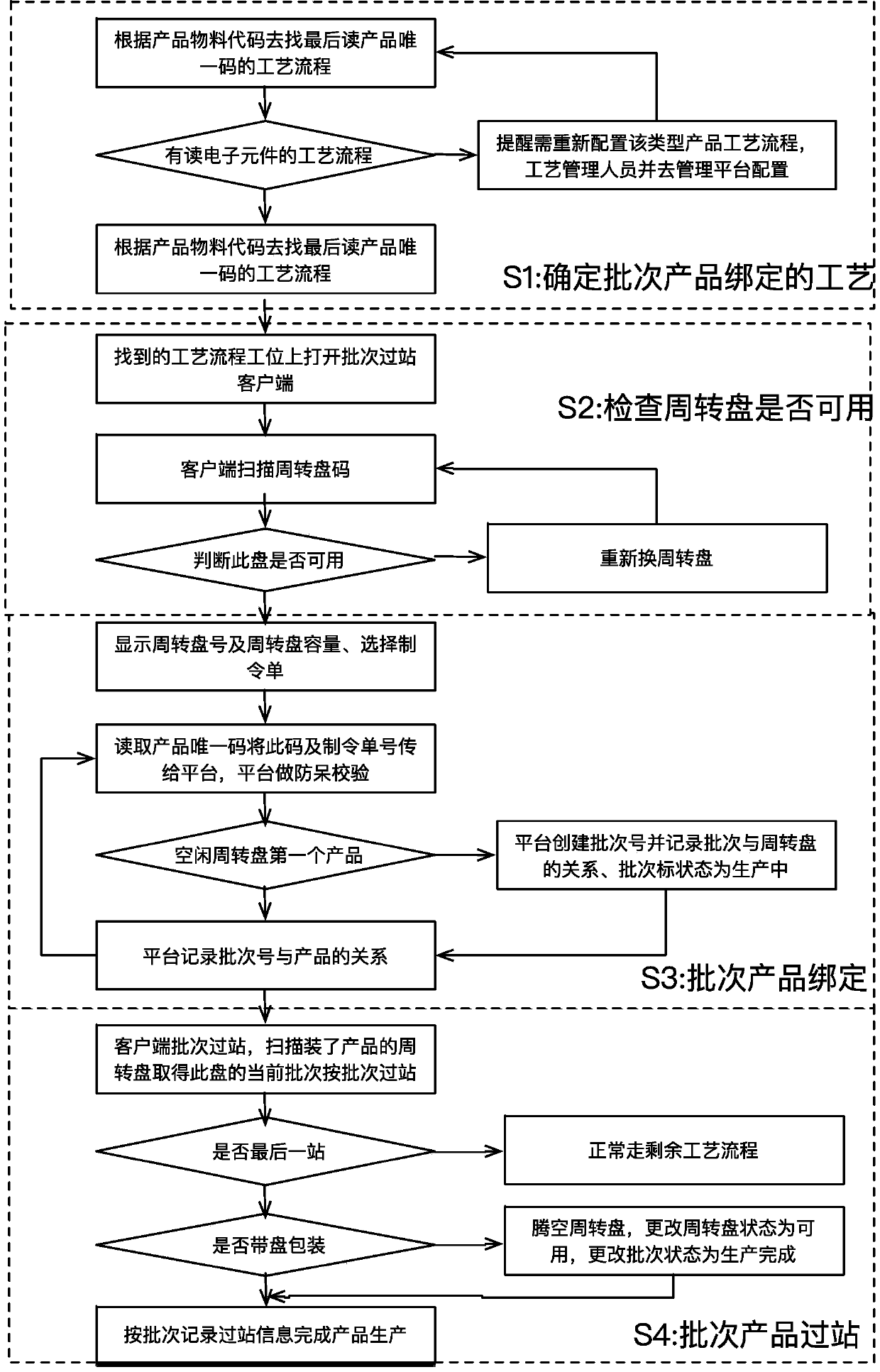

[0065] Step 2.1 assumes that product A is ready to be produced, and the process flow of A includes performance testing (the unique code written in the product needs to be read), taping and packaging. Then find the process performance test process to do the generation of product batches and the binding of batches and each product, that is, complete image 3 The S1 process in .

[0066...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com