Liquid metal flexible thin film with two-sides mutual difference characteristic and preparation method thereof

A liquid metal, flexible film technology, applied in equipment for manufacturing conductive/semiconductor layers, cable/conductor manufacturing, conductive layers on insulating carriers, etc. and other problems, to achieve the effect of simple production process, adjustable film thickness and uniform film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

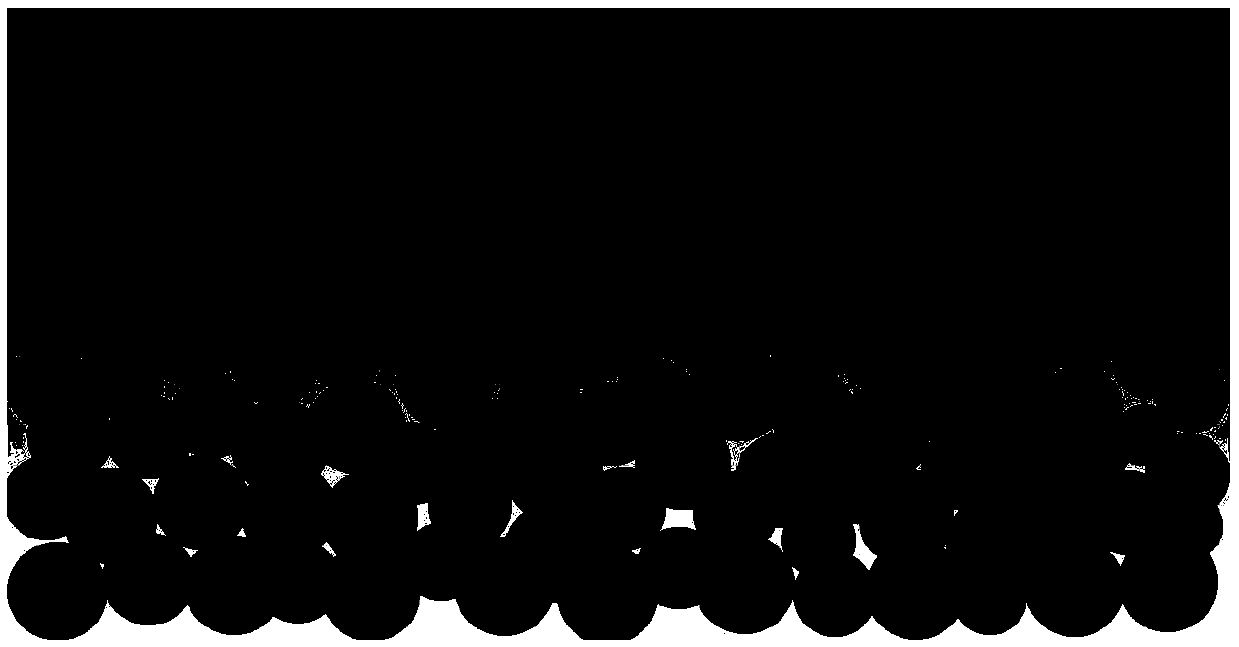

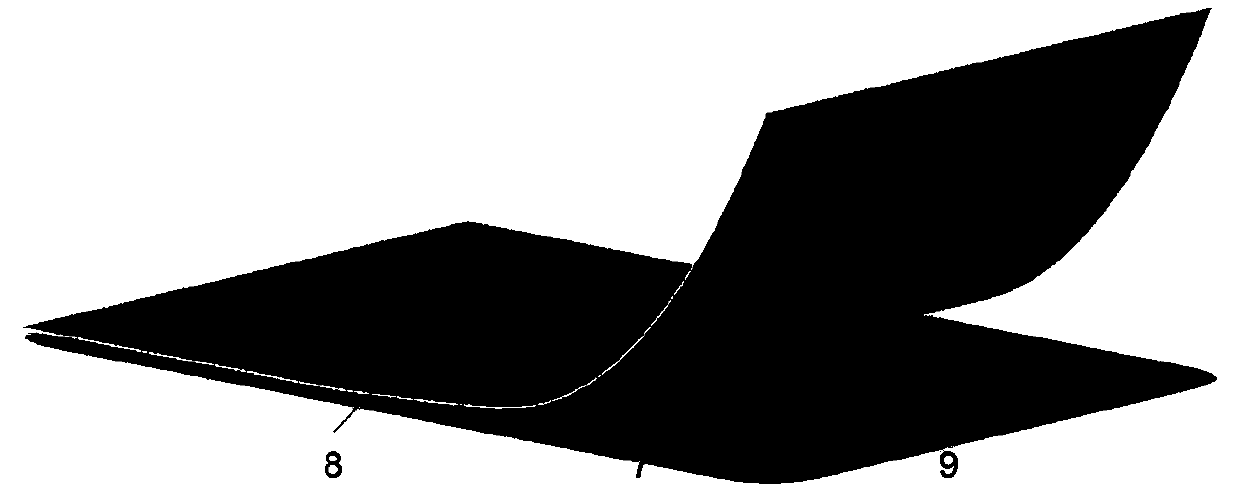

[0045] A liquid metal flexible film with different properties on both sides, the properties of the two sides of the liquid metal flexible film are different, one side is insulated, and the other side has controllable conductivity, and the conductivity is distributed in the liquid state Liquid metal realization in metal flexible film.

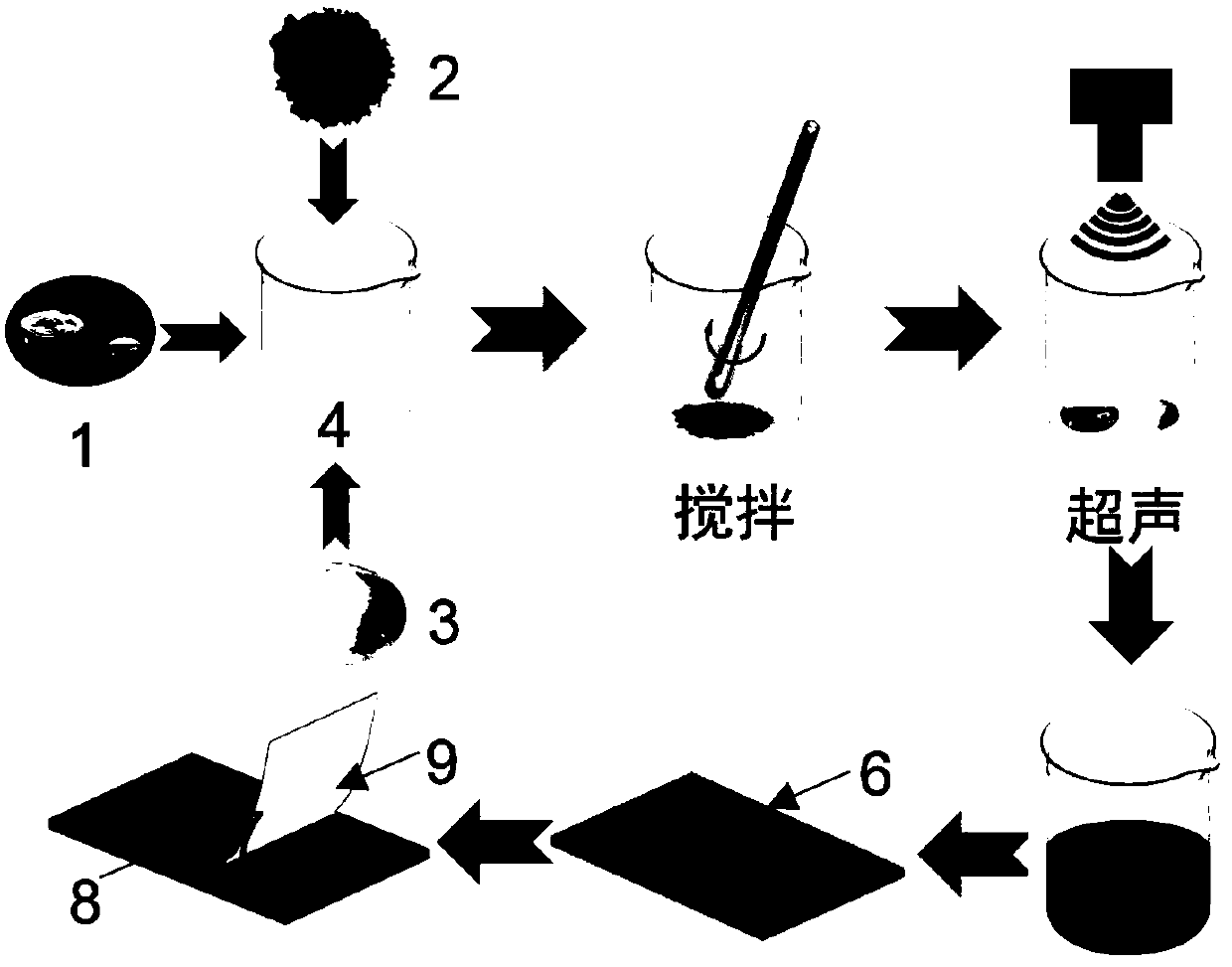

[0046] This embodiment also provides the preparation method of the liquid metal flexible film with different characteristics on both sides. For the process, see figure 1 . Specifically include the following steps:

[0047] (1) Take 10g of polyvinyl alcohol (PVA) particles and place them in a 500mL beaker, add 300mL of deionized water to swell for 2 hours, then place them in a 97°C heating box to heat and keep warm, and use a glass rod to stir continuously to fully dissolve the PVA particles. Obtain an aqueous solution of polymer material 2 with a concentration of 10g / 300mL;

[0048] (2) Take out 15g of PVA aqueous solution from the PVA aqueou...

Embodiment 2

[0055] A liquid metal flexible film with different properties on both sides, the properties of the two sides of the liquid metal flexible film are different, one side is insulated, and the other side has controllable conductivity, and the conductivity is distributed in the liquid state Liquid metal realization in metal flexible film.

[0056] The following is the preparation method:

[0057] (1) Take 10g of polyvinyl alcohol (PVA) particles and place them in a 500mL beaker, add 300mL of deionized water to swell for 2 hours, then place them in a 97°C heating box to heat and keep warm, and use a glass rod to stir continuously to fully dissolve the PVA particles. Obtain a 10g / 300mL PVA aqueous solution;

[0058] (2) Take 20g of PVA aqueous solution from 10g / 300mL of PVA aqueous solution, add 12g of liquid metal gallium, then add 6g of nanocellulose (CNC-C, solid content 9%) emulsion, 10mL of deionized water, and then stir the mixture to mix ;

[0059] (3) Sonicate the mixture ...

Embodiment 3

[0062] Embodiment 3: Preparation of flexible circuit board by needle engraving method

[0063] Using the film obtained in Example 1, complex circuits were carved on the side with controllable conductivity. The wire width can be adjusted according to the size of the tip, and the smallest wire with sub-micron thickness can be obtained.

[0064] The obtained circuit resistance characteristic was 1 Ω / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap