A kind of cable composite cross-linking process

It is a composite communication and process technology, which is applied in the direction of cable/conductor manufacturing, conductor/cable insulation, circuit, etc. It can solve the problems of large elasticity and variable type, and achieve the effect of eliminating residual charge and increasing safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

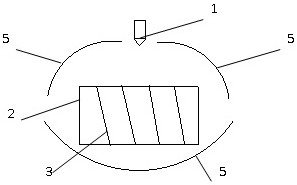

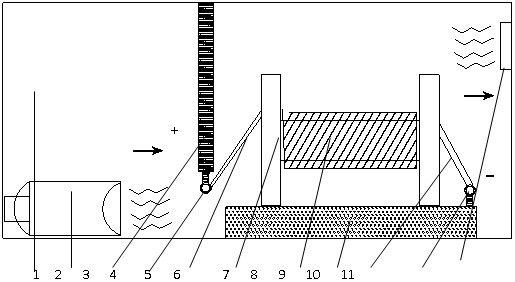

Image

Examples

Embodiment Construction

[0015] The tool torque M reaches M min +10% (M max - M min ) time corresponds to the glue burning time of the rubber material; define t90, that is, the torque M of the vulcanizer reaches Mmin +90% (M max - M min ) is the positive vulcanization time of the rubber. According to the vulcanization curve, it can be seen that the change trend of the rubber vulcanization degree is consistent with the data of the compression set value, and the data of the compression set reflects the rubber from under-vulcanization to positive vulcanization The process of gradually increasing the degree of sulfidation.

[0016] Insulated wire core vulcanization and cross-linking process

[0017] Through the torque rheometer, measure the torque M of the vulcanizer to reach M min +10% (M max - M min ) The corresponding time is the glue burning time of the rubber material; define t 90 That is, the torque M of the vulcanizer reaches M min +90% (M max - M min ) The corresponding time is the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com