Fabrication method of DBR flip chip

A flip-chip and manufacturing method technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problem that DBR flip-chip is not suitable for high-current and high-power use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

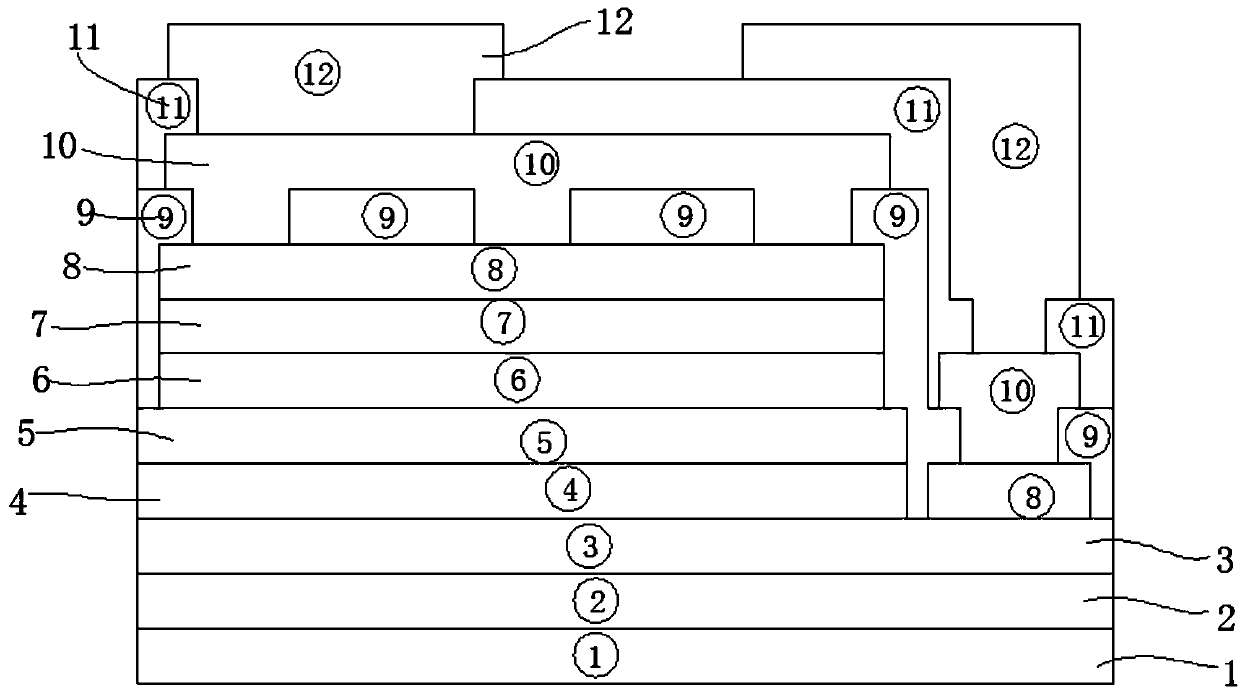

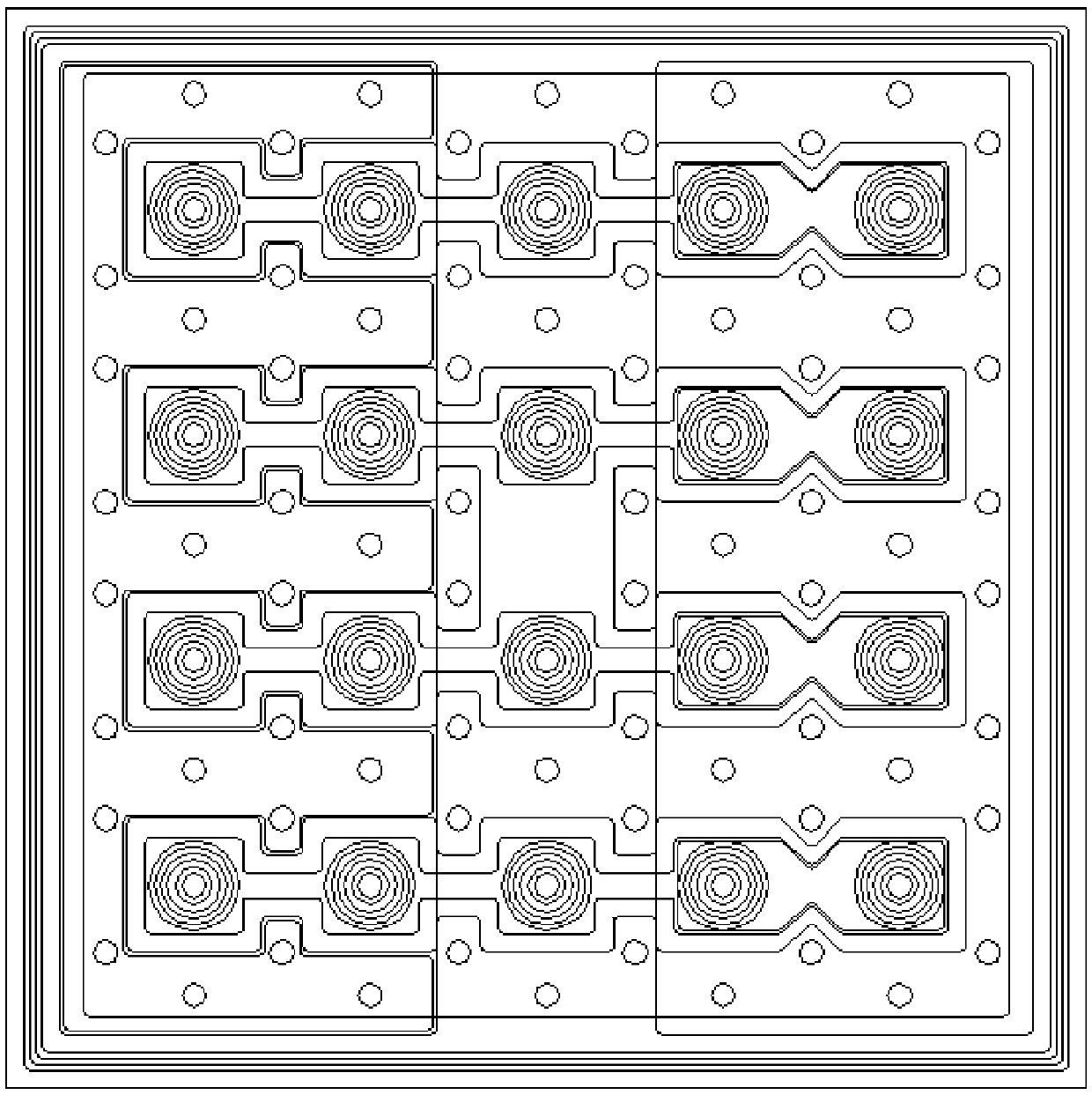

[0017] See Figure 1-2 , a DBR flip chip manufacturing method provided by the present invention, comprising the following steps: Step 1, making an epitaxial layer; specifically, Step 1 includes: sequentially growing a buffer layer on a sapphire substrate 1 by MOCVD equipment 2. N-GaN layer 3, light-emitting quantum well 4 and P-GaN layer 5, to complete the fabrication of GaN-based LED epitaxial layer. Step 2, etching an N-type step on the epitaxial layer structure, so that N-GaN is in a bare state; Step 3, growing a reflective layer and a metal binding layer 8 on the surface of the epitaxial layer; Step 4, Grow DBR Bragg reflector layer 9 on described DBR flip-chip, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap