Pipeline cleaning brush

A pipeline cleaning and cleaning brush technology, which is applied in the industrial field, can solve the problem that the pipeline does not have special work, etc., and achieve the effect of simple adjustment and efficient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

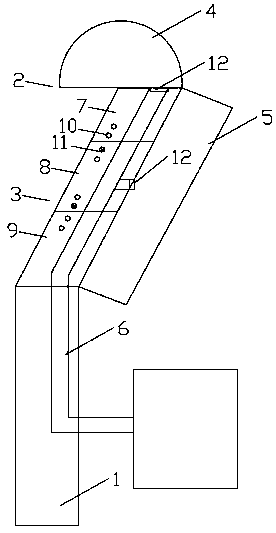

[0017] A pipe cleaning brush includes a hand-held part 1, the top of the hand-held part 1 is connected with a cleaning part 2, and the cleaning part 2 includes a telescopic rod 3, an arc surface cleaning brush 4 positioned at the top of the telescopic rod 3 and a The side facing the cleaning brush 5, the bottom of the hand-held part 1 is provided with a cleaning liquid channel 6, and the cleaning liquid channel 6 penetrates the cleaning liquid channel 6 of the hand-held part 1 and enters the cleaning part 2. Directly facing the cleaning brush 5 is connected. The present invention can divide the cleaning part into an arc part and a straight part, aiming at the arc structure of the pipeline, the arc cleaning brush 4 can be used for cleaning, and the vertical or parallel part can be cleaned by the straight cleaning brush 5 Cleaning is specially designed for pipeline cleaning.

Embodiment 2

[0019] A pipe cleaning brush includes a hand-held part 1, the top of the hand-held part 1 is connected with a cleaning part 2, and the cleaning part 2 includes a telescopic rod 3, an arc surface cleaning brush 4 positioned at the top of the telescopic rod 3 and a The side facing the cleaning brush 5, the bottom of the hand-held part 1 is provided with a cleaning liquid channel 6, and the cleaning liquid channel 6 penetrates the cleaning liquid channel 6 of the hand-held part 1 and enters the cleaning part 2. Directly facing the cleaning brush 5 is connected.

[0020] The telescopic rod 3 includes an upper casing 7, a middle pipe 8 and a lower casing 9, the upper casing 7 and the lower casing 9 are respectively sleeved on the middle pipe 8, and the side wall of the middle pipe 8 is provided with A plurality of positioning holes 10 along the length direction, the upper casing 7 and the lower casing 9 are also provided with positioning holes 10, and the latch 11 passes through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com