Pediatric dropper bottle lower cover automatic assembling machine

An automatic assembly machine and drop bottle technology, applied in the field of drop bottle caps, can solve the problems of low production efficiency and easy contamination of drop bottle caps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

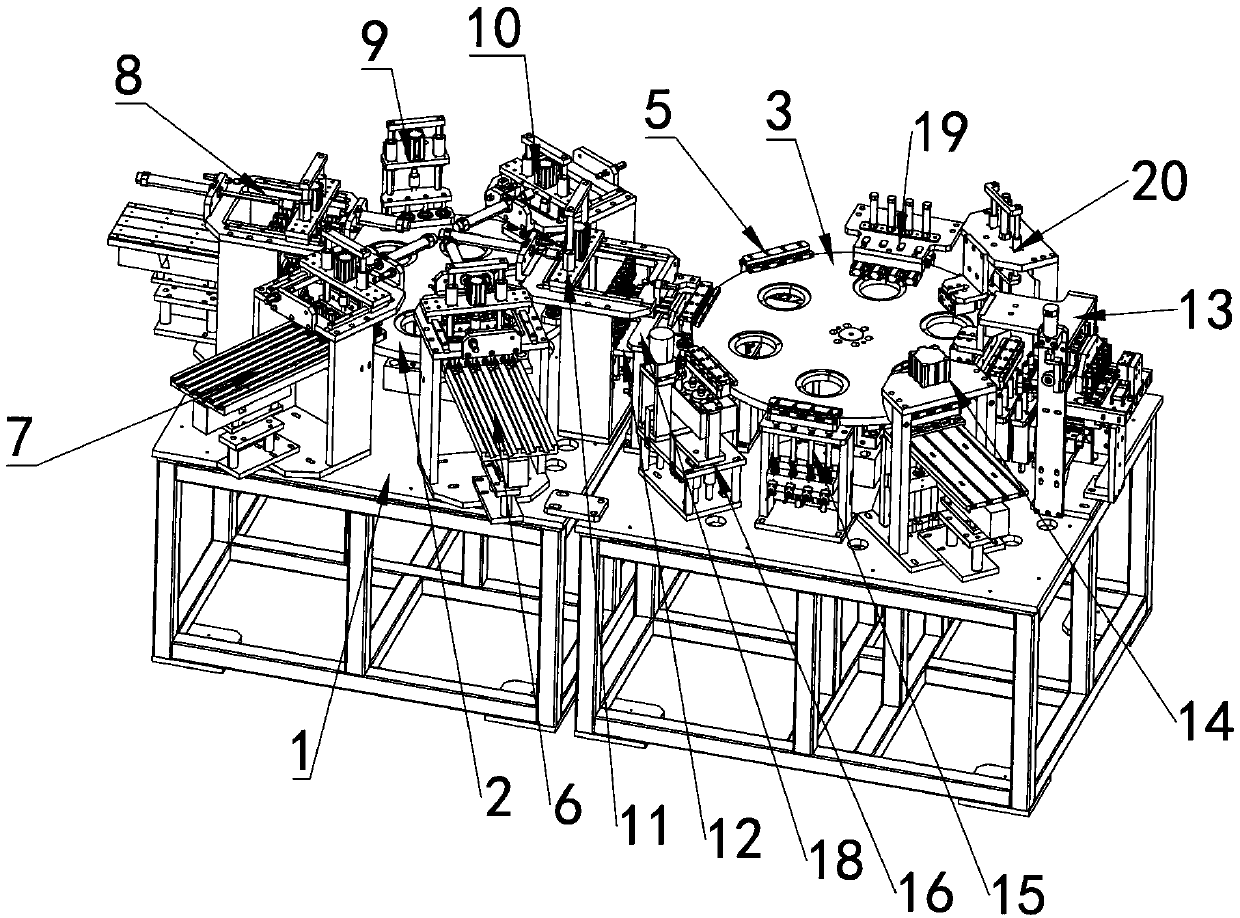

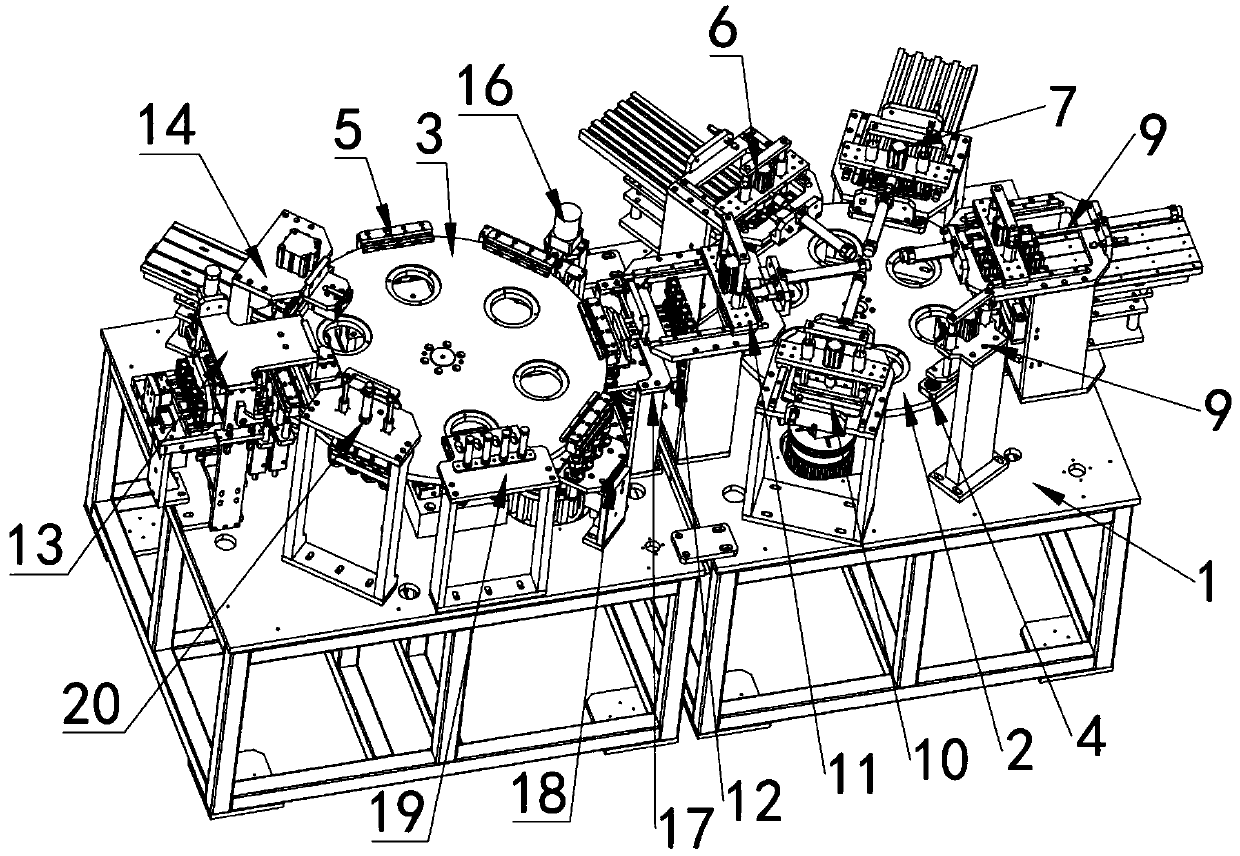

[0053] refer to Figures 1 to 19 The figure further illustrates an embodiment of the invention.

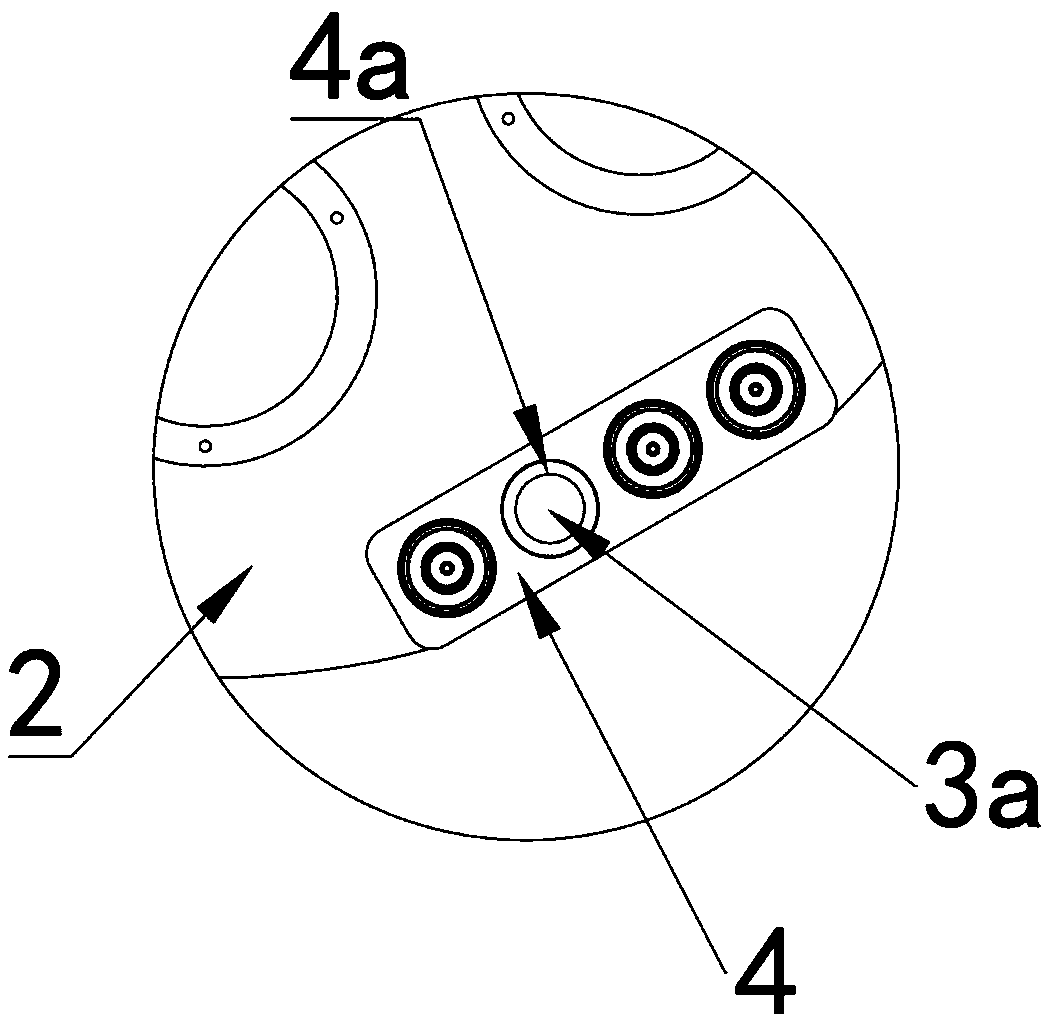

[0054] Such as figure 1 , figure 2 and image 3The shown automatic assembly machine for the lower cap of the children's drop bottle includes a frame 1, on which the adjacent turntable I2 for assembling the drip core and the turntable II3 for assembling the drip funnel and the filter screen are fixed. On the turntable I, there are several on-disk fixtures I4 arranged in the circumferential direction, and on the turntable II3, there are several on-disc fixtures II5 arranged along the circumference, the main assembly I is arranged outside the turntable I, and the group is arranged outside the turntable II3 Assembly II. There are four placement grooves 4a on the fixture Ⅰ4 on the plate, and the fixture Ⅰ4 on the plate is divided into a large drop cap fixture and a small drop cap fixture, and the large drop cap fixture and the small drop cap fixture are alternately distributed. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com