Vacuum spraying box with automatic water level control function

A spray box and vacuum technology, applied in the field of plastic pipe manufacturing, can solve the problems of water outlet pipe blockage, rough pipes, shaking rings, etc., and achieve the effect of avoiding blockage, improving the qualification rate, and small fluctuations in pressure and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

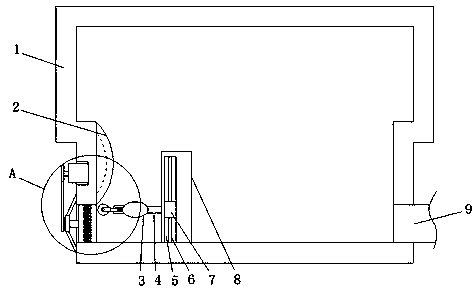

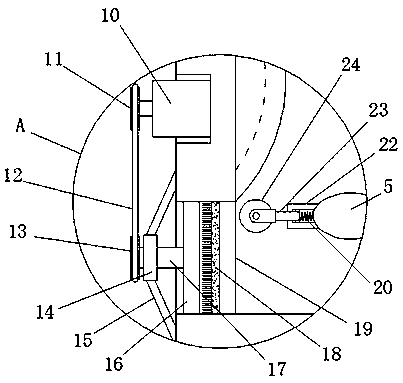

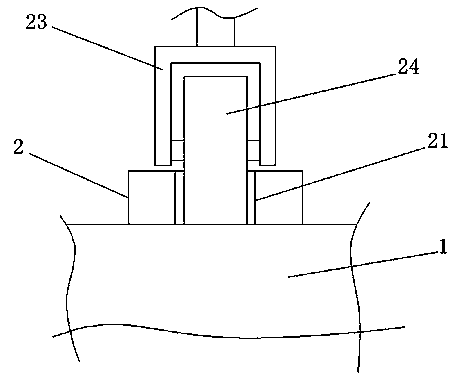

[0020] Example: During use, the cooling liquid flows into the vacuum spray box 1 from the water inlet 9, and when the water level inside the vacuum spray box 1 is high, the cooling liquid will drive the float valve 3 to rise, and the float valve 3 drives the connecting rod. 4. The connecting rod 4 drives the slider 7 to slide in the chute 5, and the slider 7 slides on the guide rod 6. During the rising process of the float valve 3, it will drive the sleeve 22, the mounting plate 23 and the conductive wheel 24. Moving up, the conductive wheel 24 will slide in the movable groove 21 on the conductive block 2, and the conductive block 2 and the conductive wheels 24 will be electrically connected, so that the controller starts the water pump at the water outlet 19 to spray the vacuum spray box 1. At the same time, the controller will start the rotating motor 10, the rotating motor 10 drives the driving wheel 11, the transmission belt 12 and the driven wheel 13 to rotate, the driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com