Preparation method of copper plate mold for pearl cotton board printing

A technology of pearl cotton and board, applied in printing plate preparation, printing, etc., can solve problems such as non-compliance with requirements, affecting product quality, and large differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

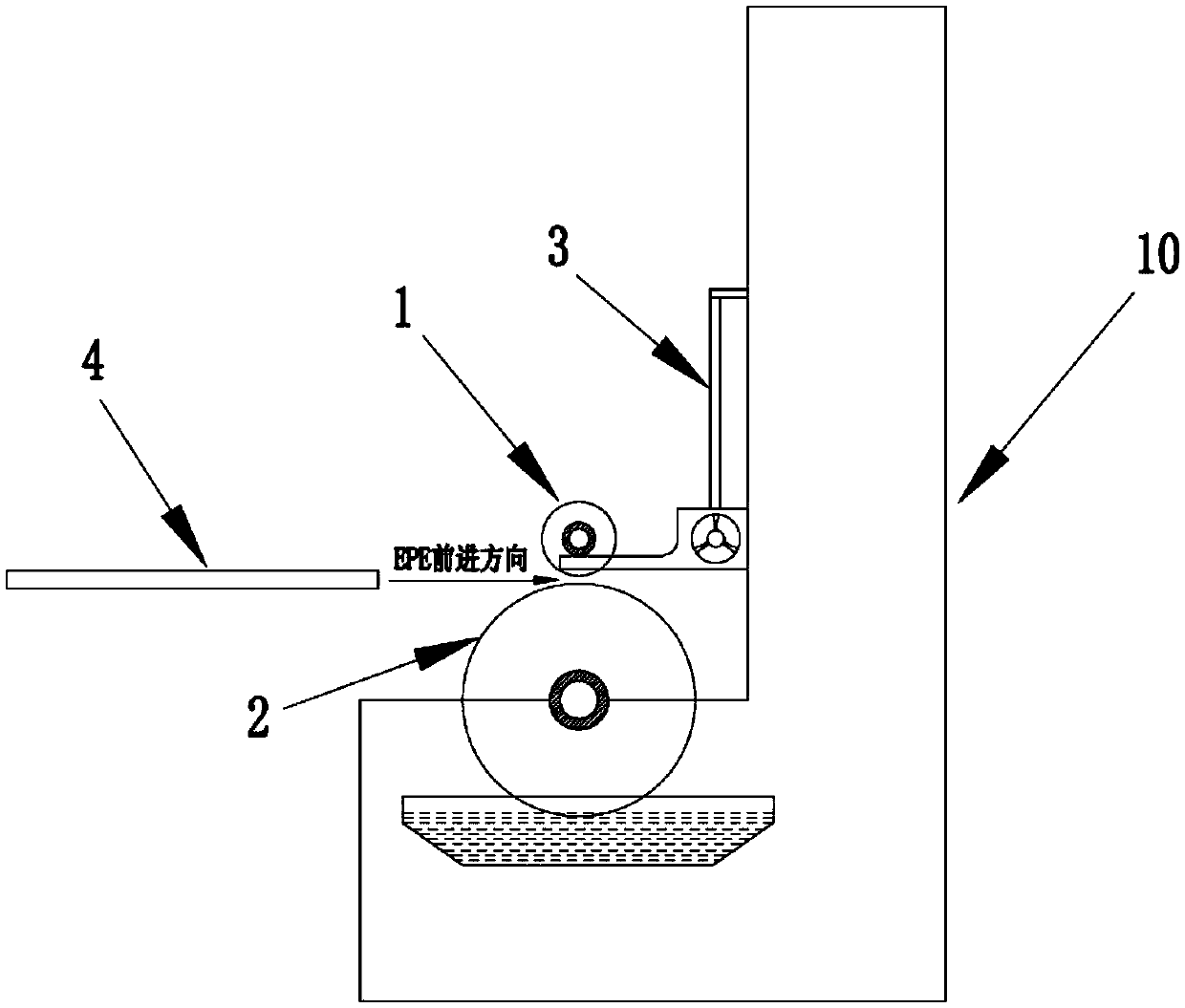

Image

Examples

Embodiment Construction

[0023] The present invention is further described in conjunction with the following examples.

[0024] A kind of preparation method of copper plate mold for pearl cotton plate printing of the present embodiment comprises the following steps:

[0025] Step a. Design the perimeter of the copper plate:

[0026] Design the perimeter of the copper plate according to the thickness of the pearl cotton plate. When the thickness of the pearl cotton plate is less than or equal to 30mm, the perimeter of the copper plate X1 = the thickness of the pearl cotton plate * 1.48 + the size of the product;

[0027] When 30mm

[0028] When 40mm

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com