Manufacturing method of anti-aging HDPE coarse surface impermeable membrane

A production method and anti-seepage membrane technology, applied in the direction of winding strips, protective devices, buildings, etc., can solve problems such as poor flexibility, full utilization of unfavorable materials, reasonable planning, and impact on construction progress, etc., to achieve high flexibility and benefit Make full use of and rationally plan to achieve the effect of effective combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0015] It should be noted that, unless otherwise specified, the technical terms or scientific terms used in this application shall have the usual meanings understood by those skilled in the art to which the present invention belongs.

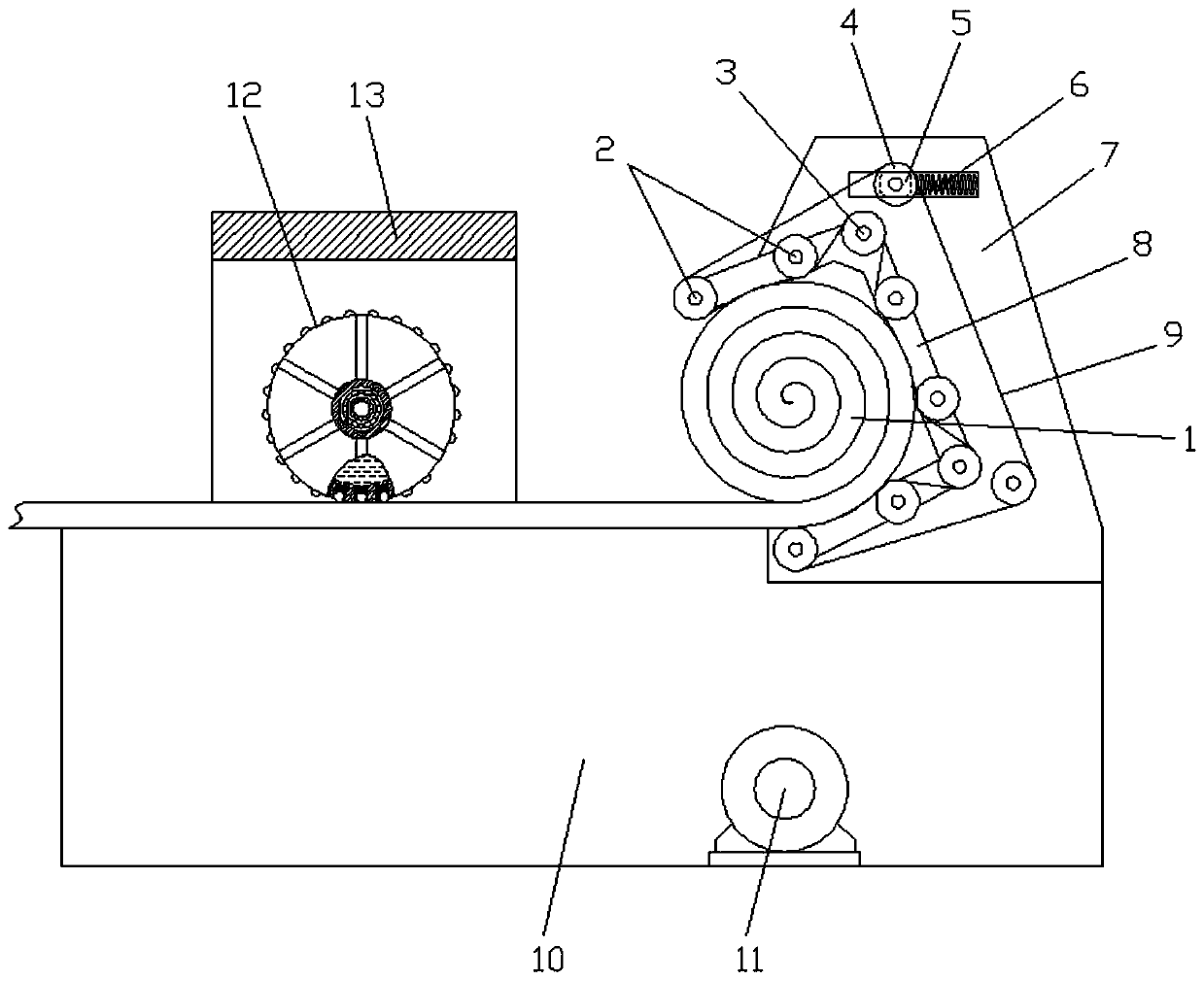

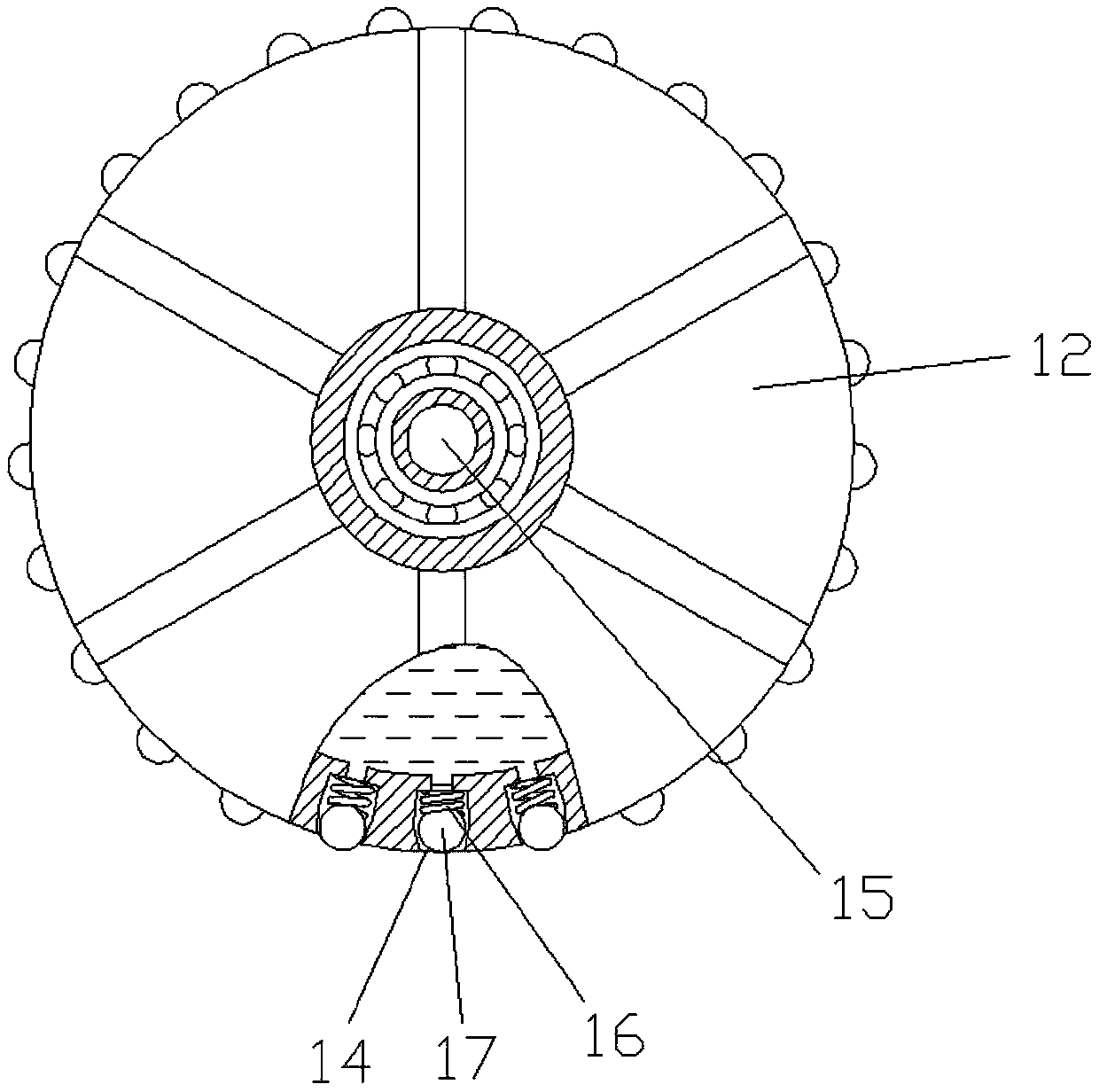

[0016] Such as figure 1 , 2 Shown: the manufacture method of a kind of anti-aging HDPE anti-seepage membrane with rough surface of the present embodiment, first put the anti-seepage membrane coil into the uncoiling device, and put the end of the anti-seepage membrane coil along the working table of the uncoiler Spread out, and then press the synchronous roller above the workbench o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com