Tube and sleeve transport system for automatic winder

A technology of automatic winding machine and conveying system, which is applied in the direction of transportation and packaging, textile and paper making, and conveying filamentous materials, etc., to achieve the effect of efficient completion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

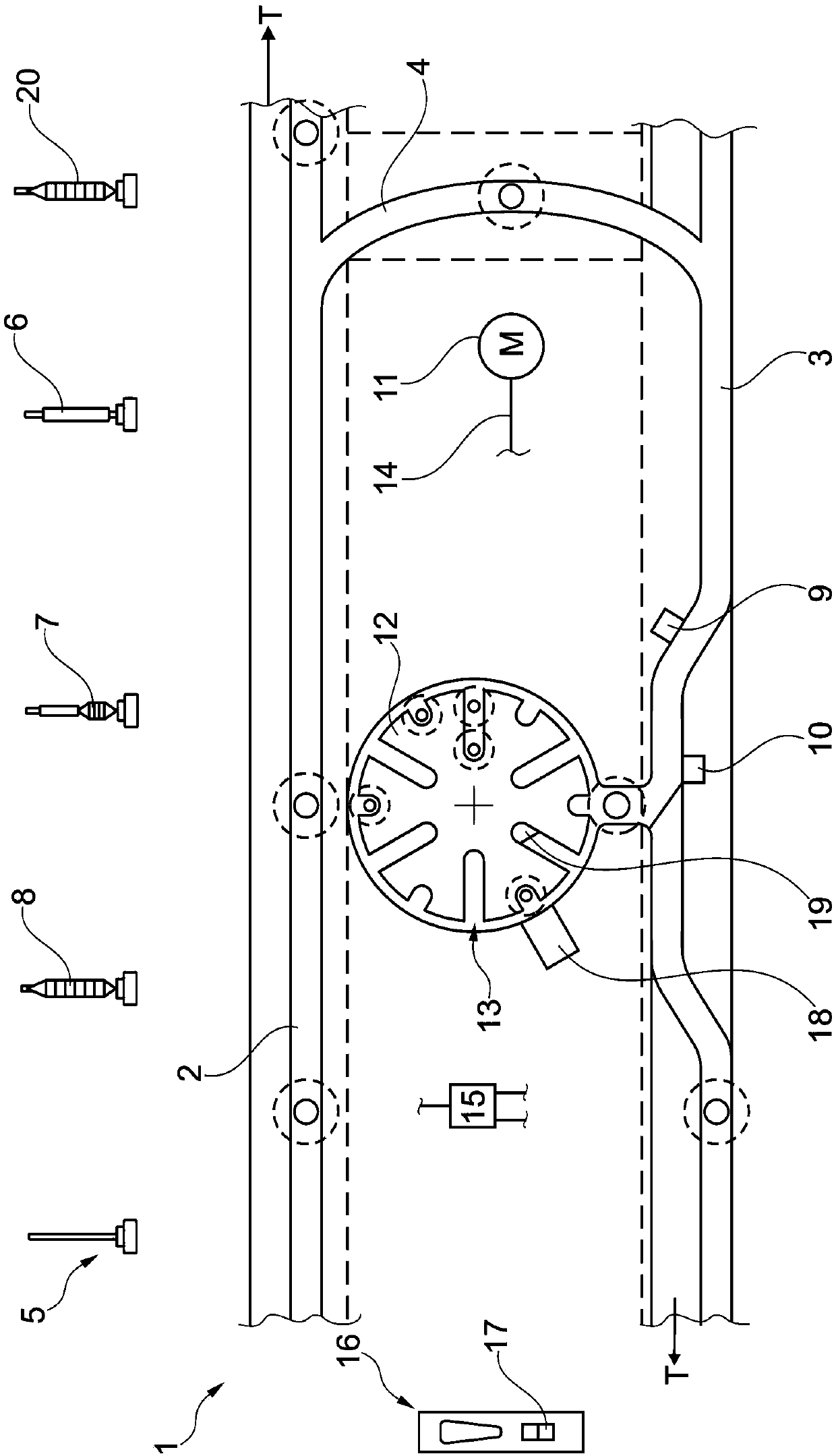

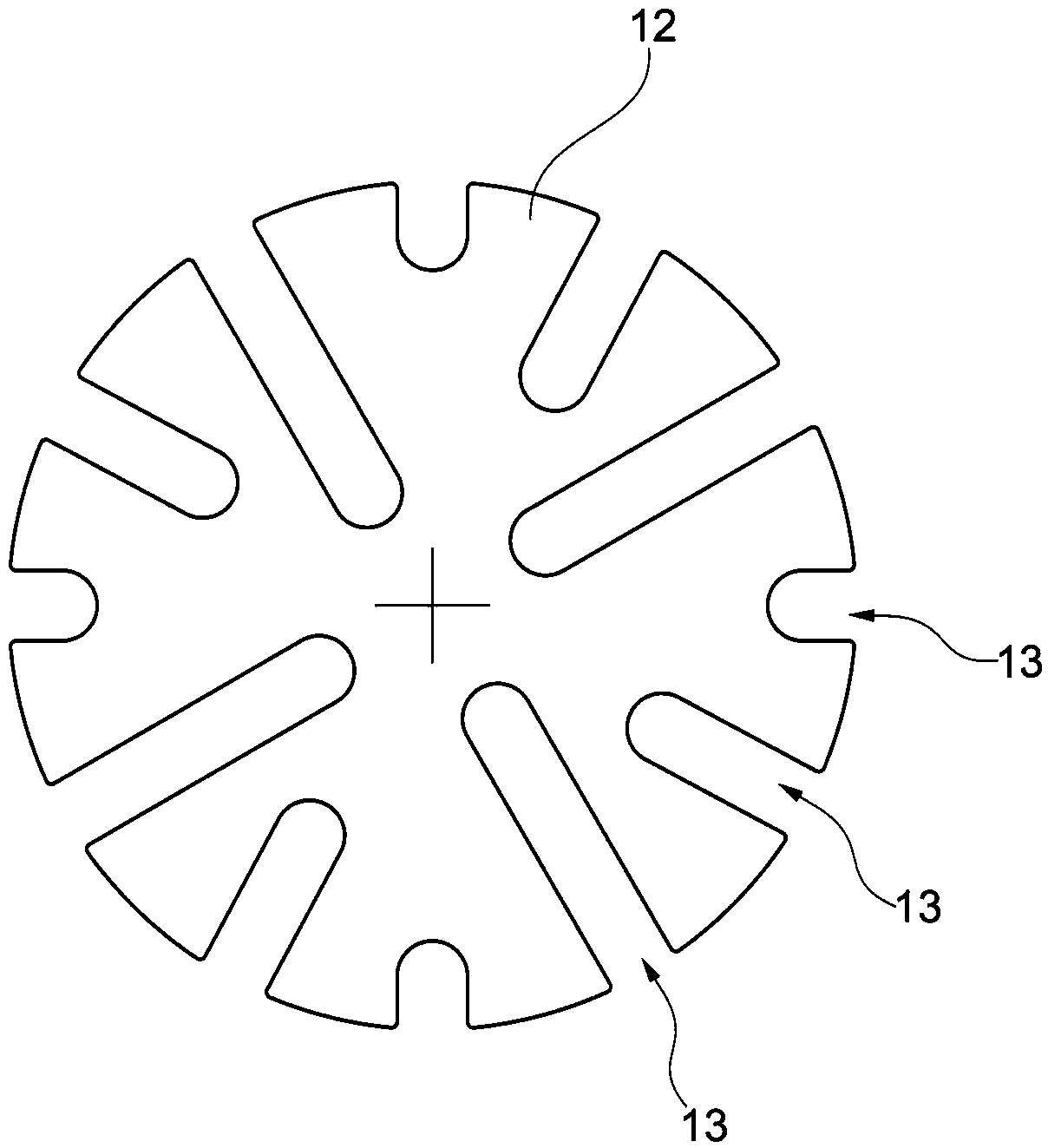

[0062] figure 1 A section of the bobbin and bobbin delivery system 1 of a winding machine, which is not shown in detail, is shown schematically. The bobbin and bobbin conveying system 1 is either directly connected to the corresponding conveying system of the ring spinning machine, or the conveying tray 5 circulated for the bobbin or bobbin conveying is equipped with bobbins from a store.

[0063] This bobbin and tube conveying system 1 known per se has a number of different conveying sections through which the winding positions of the winding machine are supplied with bobbins or empty unwound bobbins 6 are removed.

[0064] During the winding operation, a large number of transport discs 5 (with guide seats between the base plate and the cartridges) circulate in the transport direction T in the bobbin and tube transport system 1, either equipped with Full bobbin 8, remaining bobbin 7, alarm bobbin 20, or empty bobbin 6 that has been unwound.

[0065] The conveying of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com