A trolley type annealing furnace

An annealing furnace and trolley-type technology, which is applied to furnaces, furnace types, heat treatment furnaces, etc., can solve the problems of uneven temperature of the workpiece, asynchronous heating, slow cooling speed, etc., to save the annealing cycle, reduce production costs, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

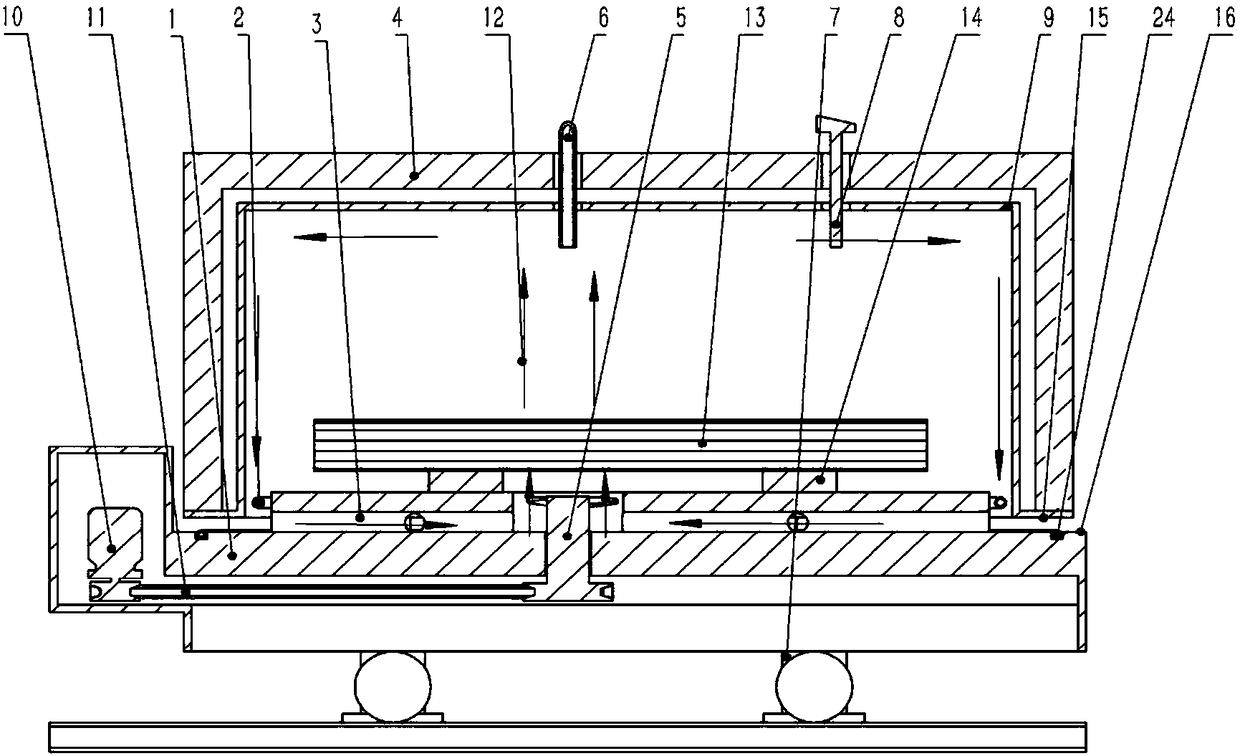

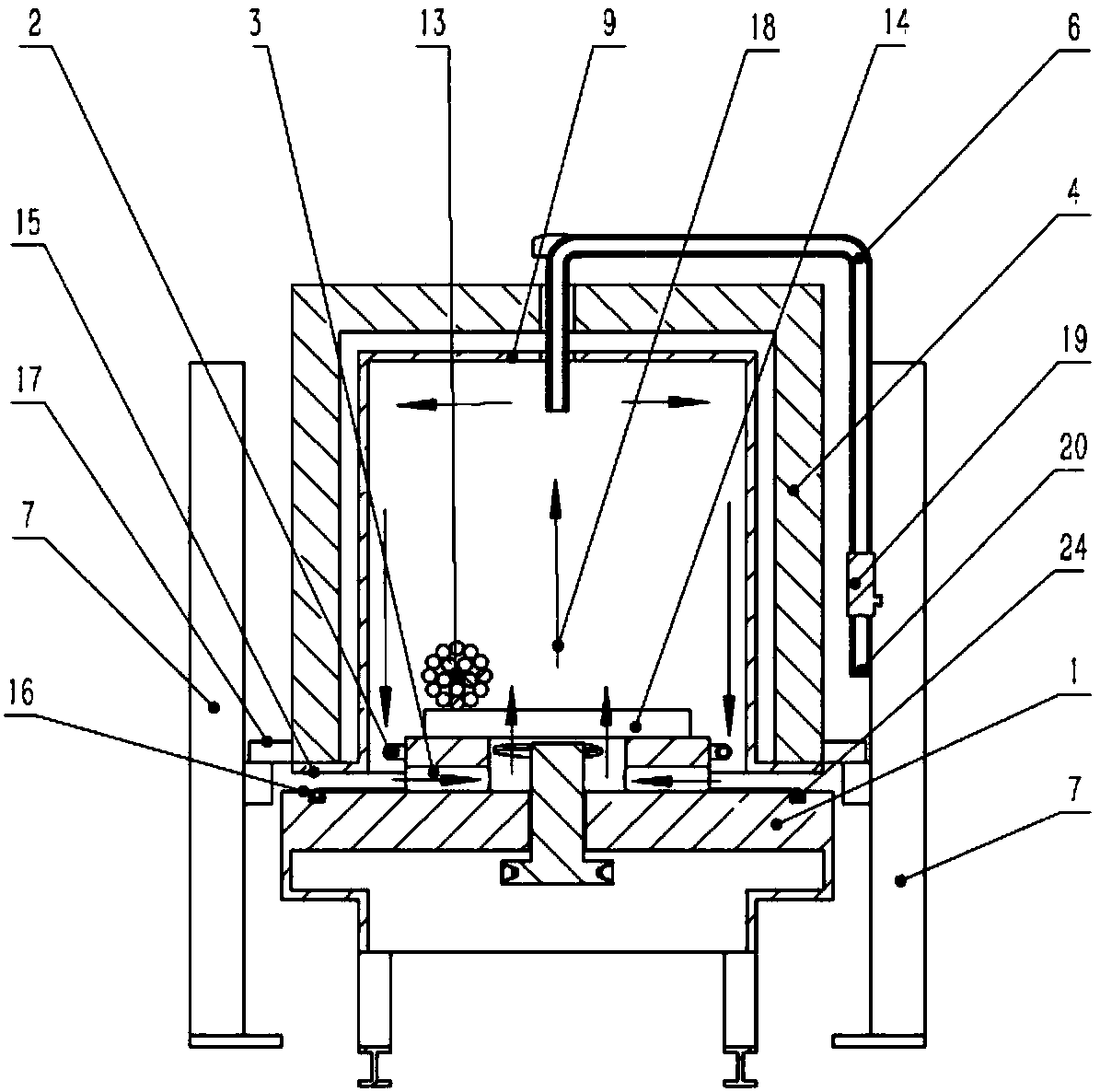

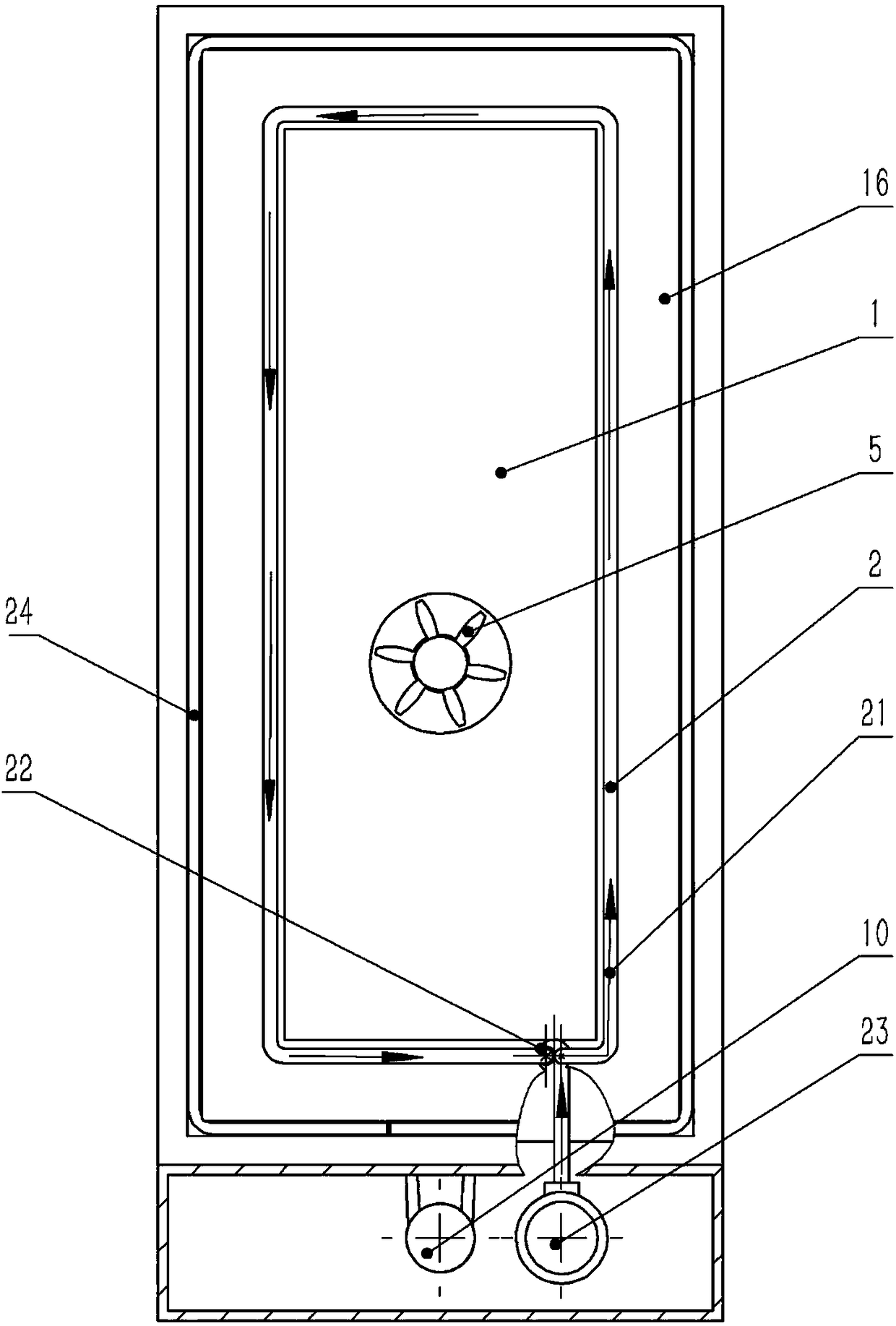

[0022] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

[0023] Such as Figure 1-Figure 2 As shown, the present invention provides a trolley-type annealing furnace, comprising: a trolley 1, a furnace body 4, and the furnace body 4 is sealed on the trolley 1 by fastening by its own gravity;

[0024] A motor 10 is arranged on the trolley 1, and the motor 10 is connected with an axial flow fan 5 through a triangular tape 11, and a workpiece 13 is placed above the axial flow fan 5;

[0025] Between the workpiece 13 and the trolley sealing surface 16 of the trolley 1, a return air duct 3 is laid horizontally and vertically, and the horizontally and vertically laid return air duct 3 forms a wind tunnel at the central i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com