Separation insulation phase change radiator and heat dissipation method thereof

A phase change heat exchanger and radiator technology, applied in the direction of cooling/ventilation/heating transformation, can solve the problems of large size, poor heat conduction and heat exchange performance, and poor thermal conductivity of natural convection radiators, so as to improve the phase The effect of changing heat transfer performance, improving heat dissipation performance, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the present invention is described below through specific specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

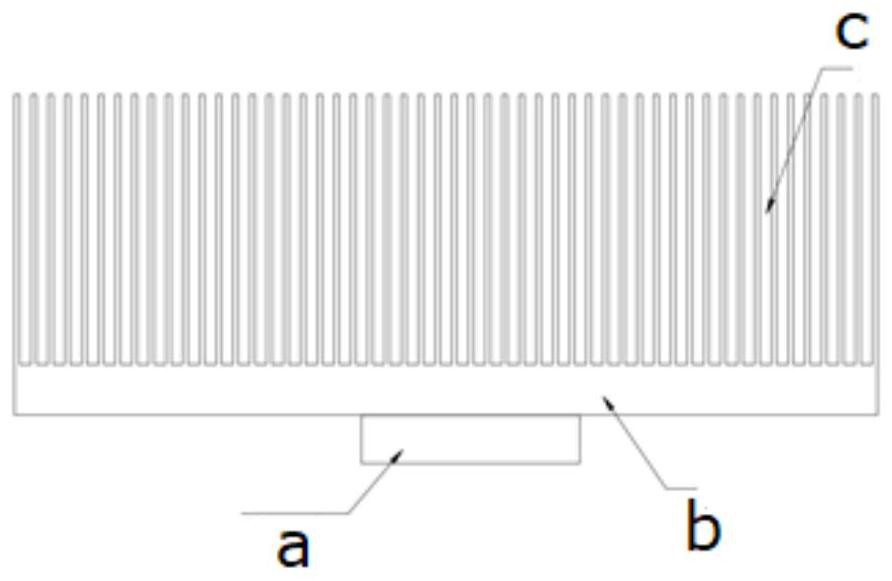

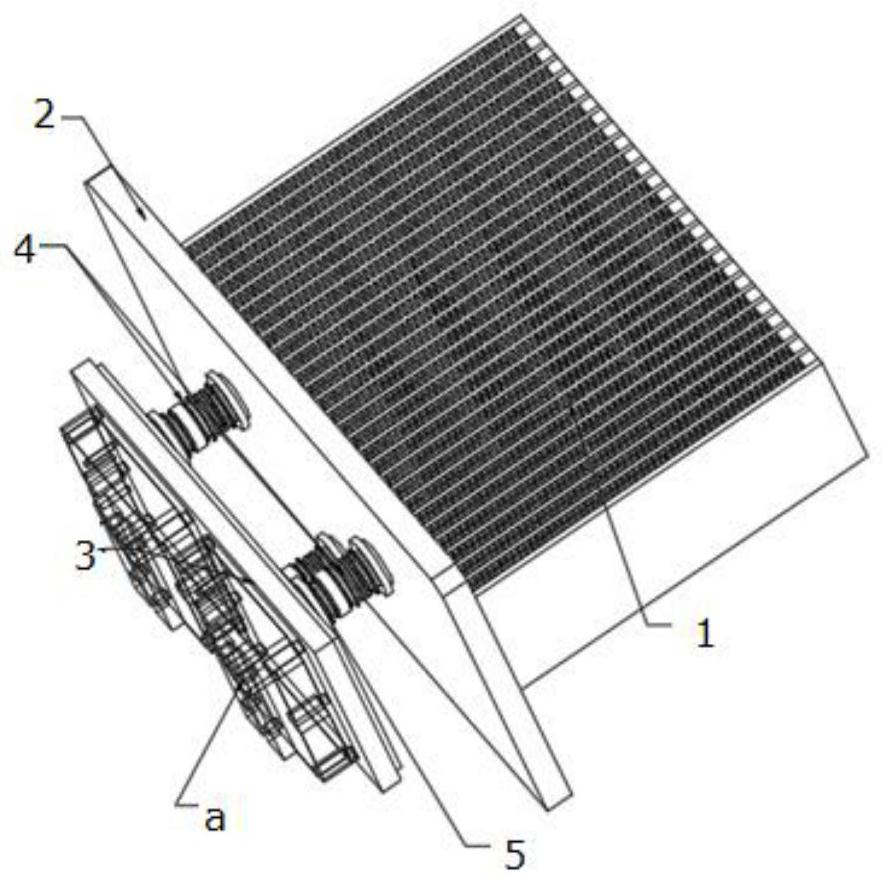

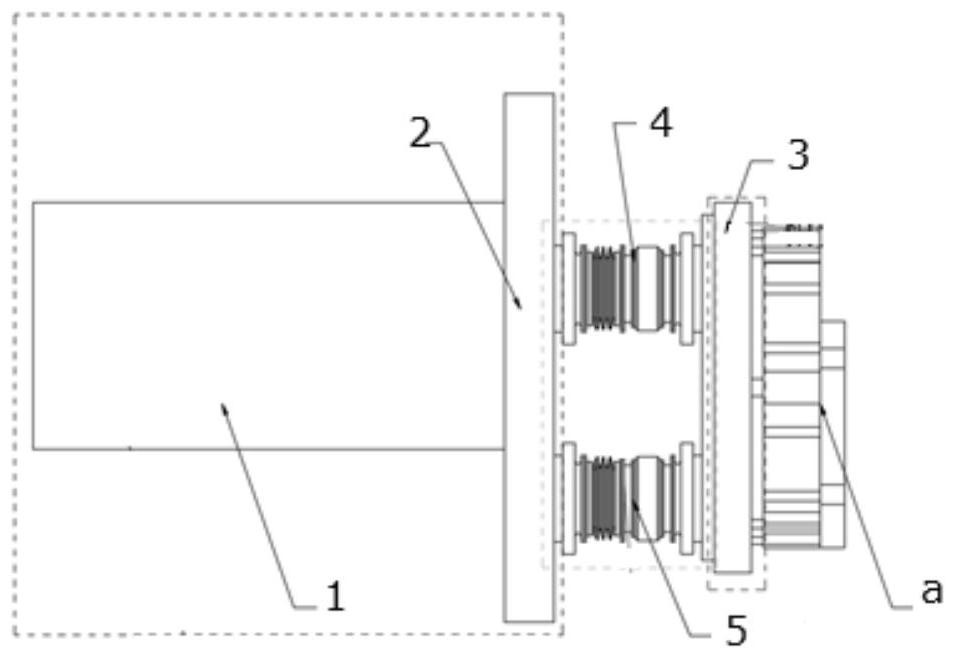

[0026] Such as figure 2 and 3 As shown, a separated insulating phase-change heat sink of the present invention is composed of three functional modules: a phase-change functional substrate assembly, a working fluid insulation channel assembly, and a phase-change heat exchanger assembly. The phase change heat exchanger assembly is composed of a heat dissipation phase change substrate 2, a phase change fin 1-2, a heat exchange fin 1-3, a heat exchanger side plate 1-1 and other structural parts (such as Figure 4 shown); the working fluid insulation channel assembly is divided into steam insulation channel 4 and condensate return flow insulation channel 5, this assembly consists of radiator side aluminum-stainless steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com