Suction bucket guide frame with high mounting efficiency

A technology for installation efficiency and suction bucket, which is applied in construction, sheet pile walls, foundation structure engineering, etc., can solve problems such as low construction efficiency, misplacement of suction bucket installation, and offset of suction bucket, so as to improve operation safety and maintain stability Sexuality, the effect of avoiding falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

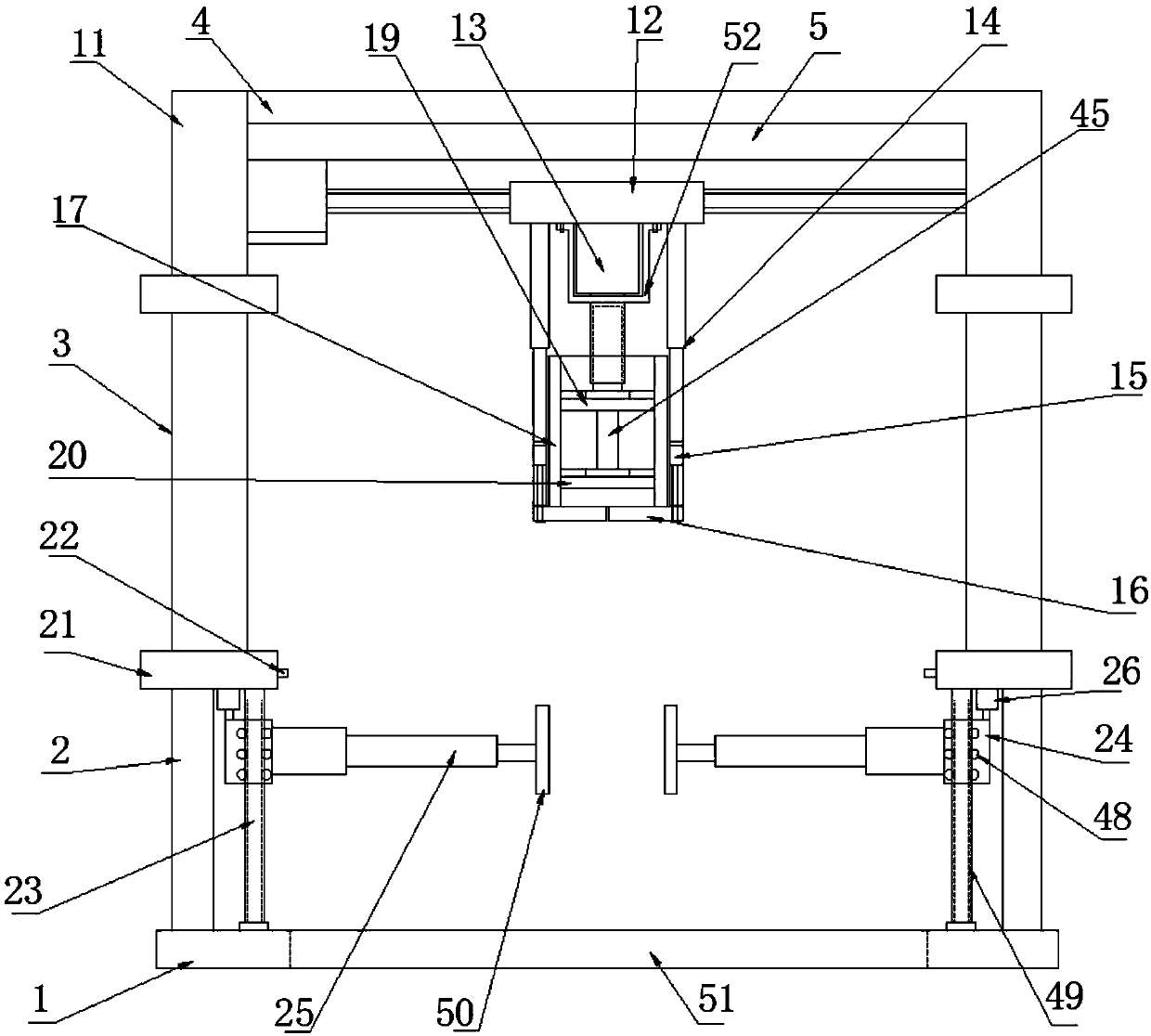

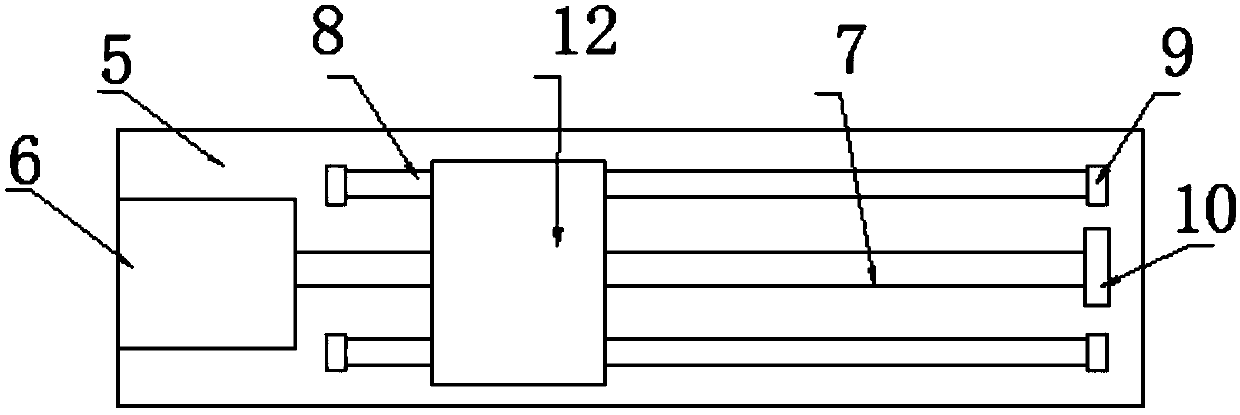

[0028] Such as Figure 1-5As shown, the suction barrel guide frame with high installation efficiency according to the embodiment of the present invention includes a horizontal plate-1, and a support rod-2 is symmetrically provided on both sides of the top of the horizontal plate-1, and the top of the support rod-2 Mounting seats 21 are provided, and infrared sensors 22 are provided on the corresponding sides adjacent to the mounting seats 21, and the two sides of the top of the horizontal plate-1 are provided with a limit position between the adjacent support rods-2. Rod 23, the limit rod 23 is connected with the bottom end of the mounting seat 21, the limit rod 23 is provided with a movable seat 24, the top of the movable seat 24 is arranged on the bottom of the mounting seat 21 The electric telescopic rod one 26 at the end is connected, and the corresponding side of the adjacent movable seat 24 is provided with a clamping mechanism, and the top of the mounting base 21 is pro...

Embodiment 2

[0031] Such as figure 1 , 5 As shown, the two adjacent support rods 11 and the second horizontal plate 4 are integrally formed, and the two support rods 11 and the second horizontal plate 4 form an inverted U-shaped structure, and the first swing plate 36 and the second swing plate 37 are arranged symmetrically about the center. The support rod 2 11 and the horizontal plate 2 4 form an inverted U-shaped structure, which is convenient for fixing the mounting plate 5 .

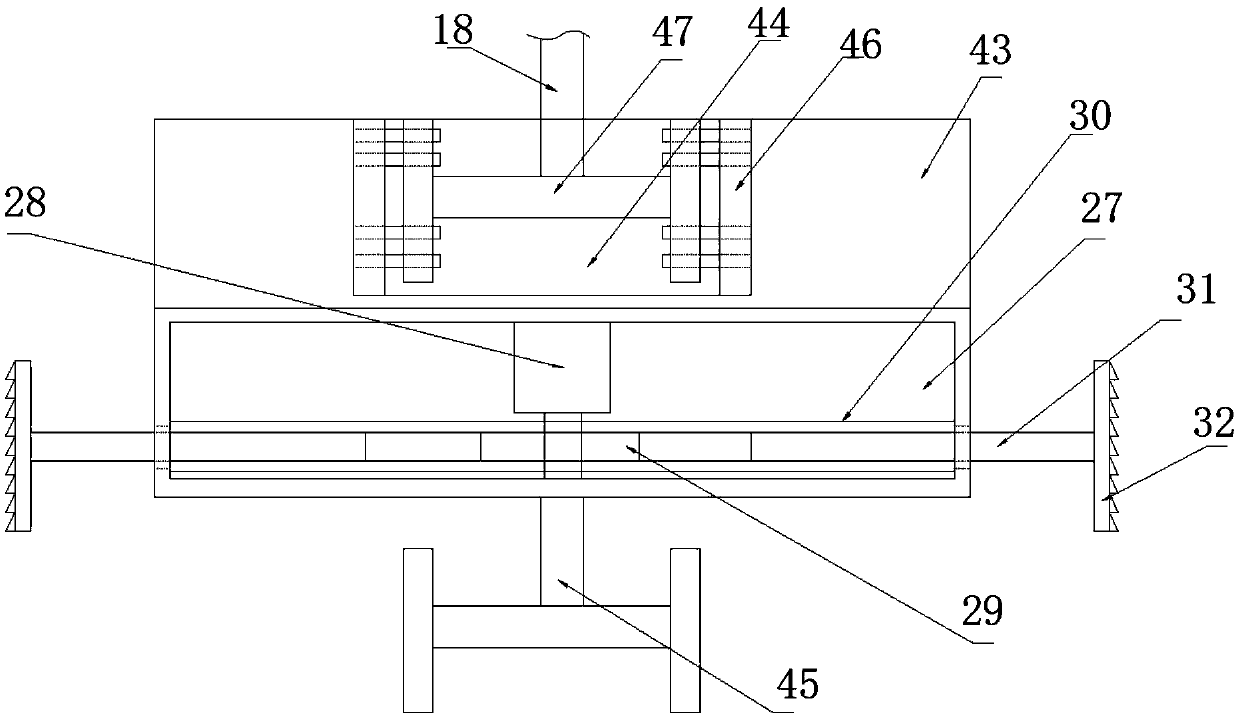

[0032] Such as Figure 5 As shown, the second fixed box 33 is a circular structure, the first fixed box 27 is a rectangular structure, and both sides of the second fixed box 33 are provided with through grooves 39 that are compatible with the clamping plate 38 . Through the provided through slot 39 , the movement of the clamping plate 38 is facilitated, thereby realizing the clamping of the suction barrel 17 .

[0033] Such as Figure 5 As shown, the side of the swing plate 2 37 close to the swing plate 36...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com