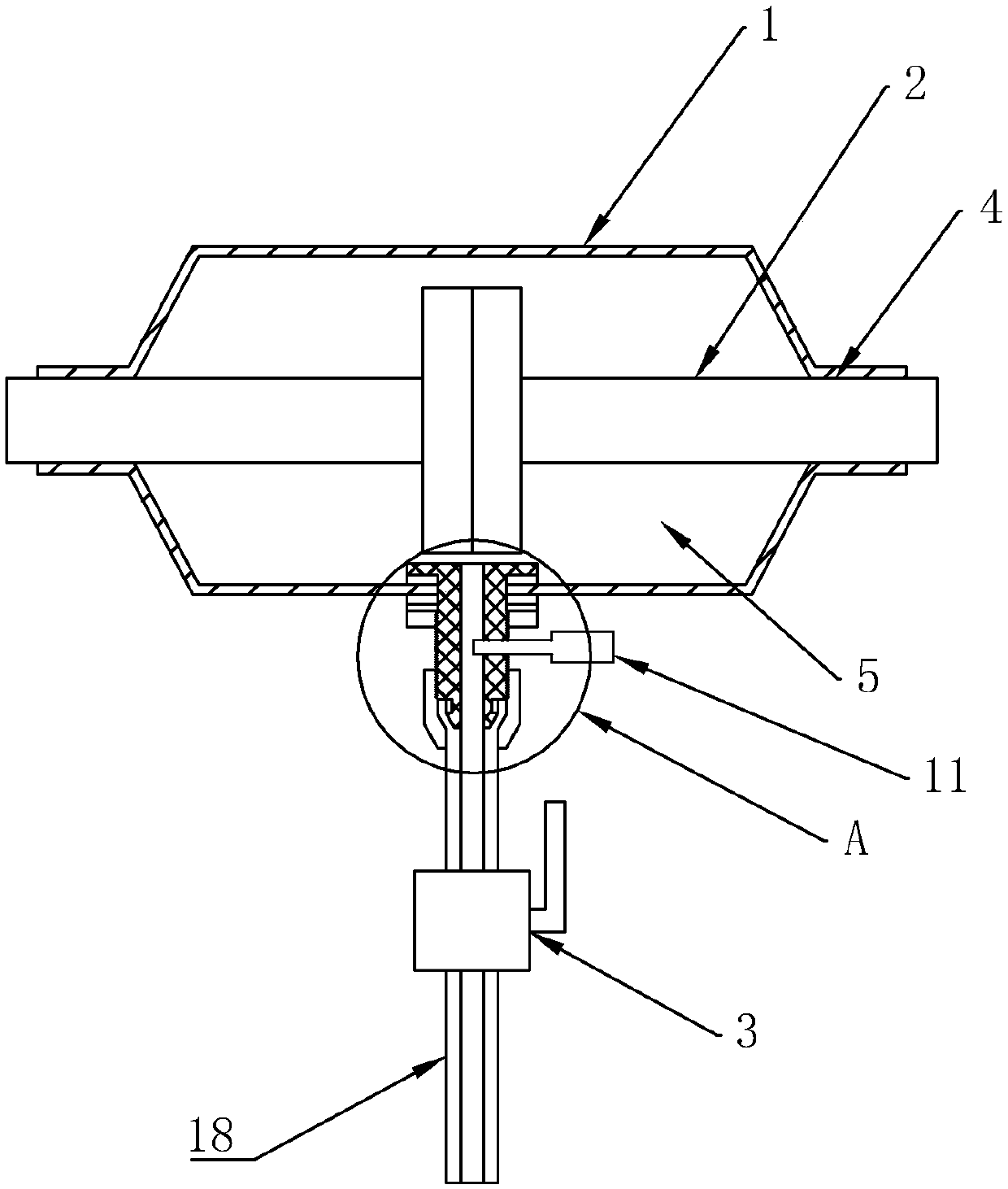

Pipeline leakage detection device

A detection device and pipeline leakage technology, which is applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., and can solve problems such as toxicity, danger, and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

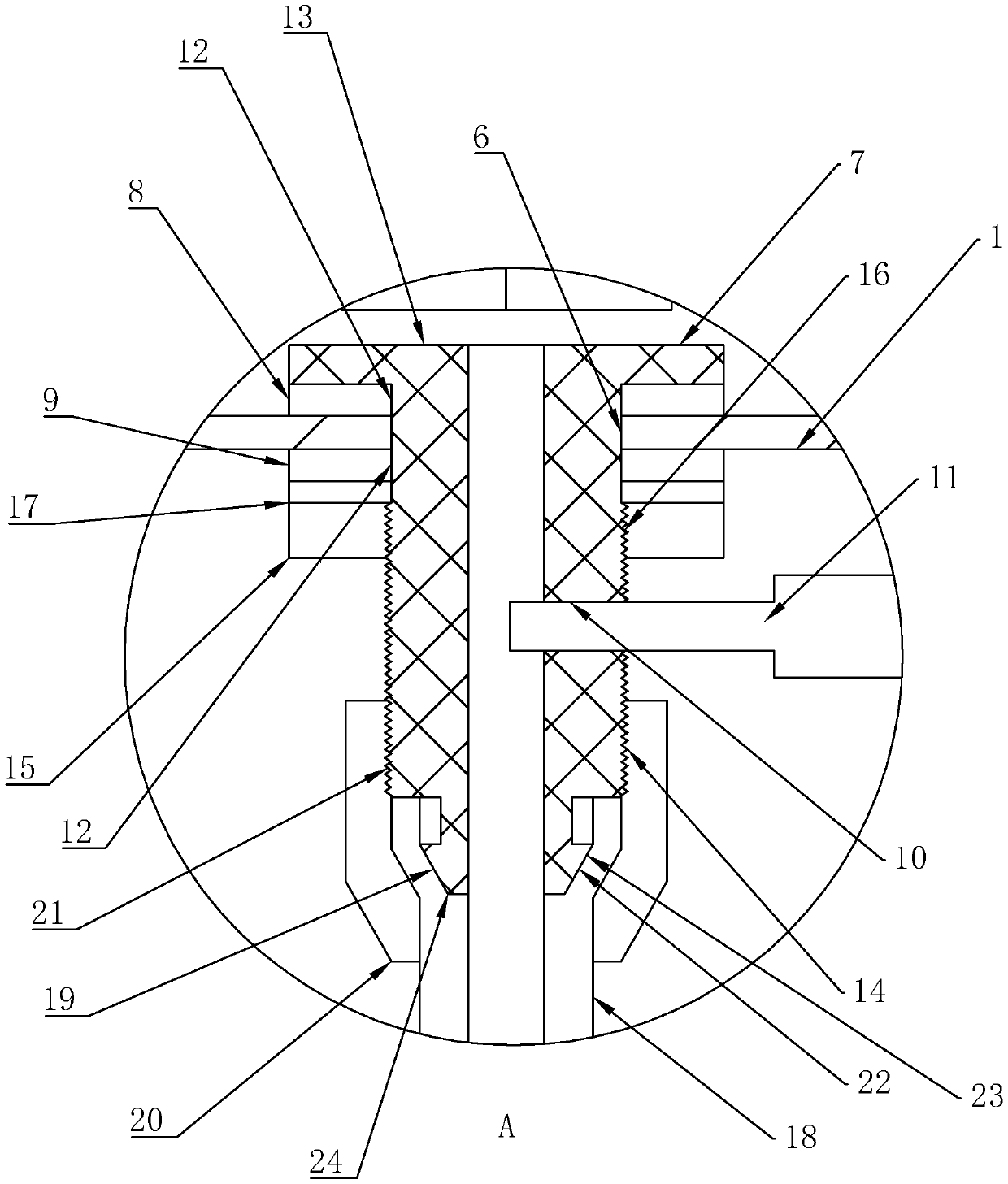

[0036] The first clamping member 8 and the second clamping member 9 are rubber blocks, and both are provided with a through hole 12 for the vacuum tube 7 to pass through.

[0037] Through the above technical solution, rubber blocks are used in the selection of the first clamping member 8 and the second clamping member 9. Through the interference fit of the rubber blocks, the rubber blocks are deformed and the protective cover 1 is better clamped. Improve the sealing effect on the through hole 6.

[0038] As a specific implementation of improvement,

[0039] An end of the vacuum tube 7 located in the sealed space 5 is provided with a resisting disk 13, and the first clamping member 8 is located between the resisting disk 13 and the protective cover 1.

[0040] Through the above technical solution, through the arrangement of the resisting disc 13, it can be possible that the first clamping member 8 can be resisted by the resisting disc 13, so as to have a supporting force for the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com