Defrosting control method and air source heat pump system

A control method and air temperature technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as misdefrosting faults, threats to safe operation of units, energy loss, etc., to achieve accurate judgment, easy promotion and use, and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

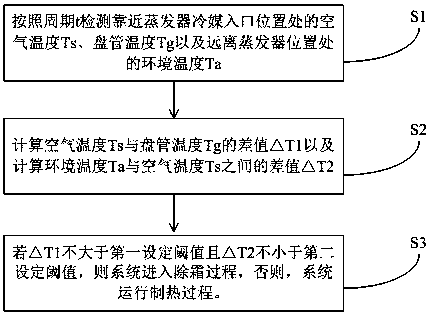

Method used

Image

Examples

Embodiment 1

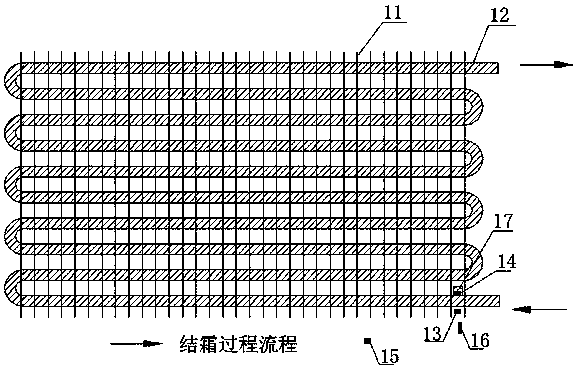

[0030] Embodiment 1, when the air source heat pump is in heating operation under the condition of low ambient temperature in winter, frost usually forms on the surface of the finned tubes of the evaporator. During the frosting process, the distribution of the frost layer on the fin surface is related to the The temperature of the surface of the tube is related to the temperature of the surface of the finned tube and the flow and heat transfer characteristics of the refrigerant. Studies have shown that when the low-temperature refrigerant flows in the tube, the pressure of the refrigerant will gradually decrease due to the frictional resistance of the tube wall. The impact of resistance pressure drop is very large, and the change of refrigerant flow rate is related to the gas-liquid ratio of refrigerant. The larger the proportion of liquid (the greater the mass), the smaller the refrigerant flow rate (usually between 0.5-1.0m / s) , with the heat absorption and vaporization of th...

Embodiment 2

[0052] Embodiment 2. This embodiment proposes an air source heat pump system, including a compressor and an evaporator. The evaporator includes a coil tube 11 and a coil tube 12 fixed on the fin 11. On one side of the fin 11 and the coil tube, There is also a fan (not shown in the figure) on the side. The fins 11 and the coil 12 are perpendicular to each other to form a fin tube. The fan is located on one side of the fin 11 and the coil 12. When the fan is running, the suction air flows through the fins. The pipe structure exchanges heat with the low-temperature refrigerant in the coil 12. The flow direction of the refrigerant during the heating process of the heat pump system is shown by the arrow. A first temperature sensor 13 is installed near the refrigerant inlet of the evaporator. The second temperature sensor 14, the temperature sensing surface of the second temperature sensor 14 is closely attached to the coil pipe, and is used to detect the temperature of the coil pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com