Female contact

A contact part and female mold technology, which is applied in the direction of contact parts, parts of connecting devices, connections, etc., can solve problems such as reliability decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be described below.

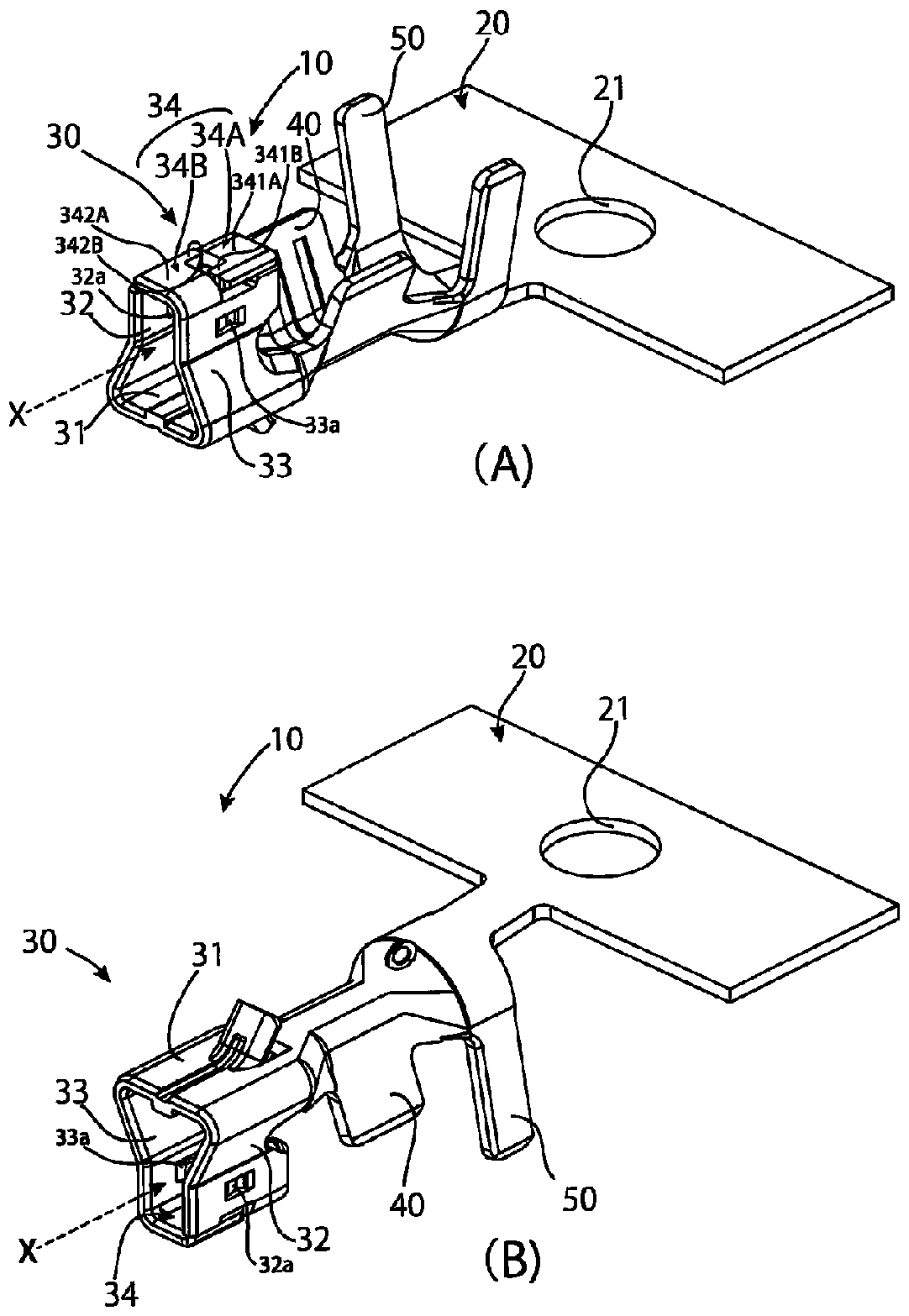

[0033] figure 1 It is a perspective view of the die contact which is one embodiment of this invention. here, figure 1 (A) and (B) are perspective views showing the same female die contact upside down.

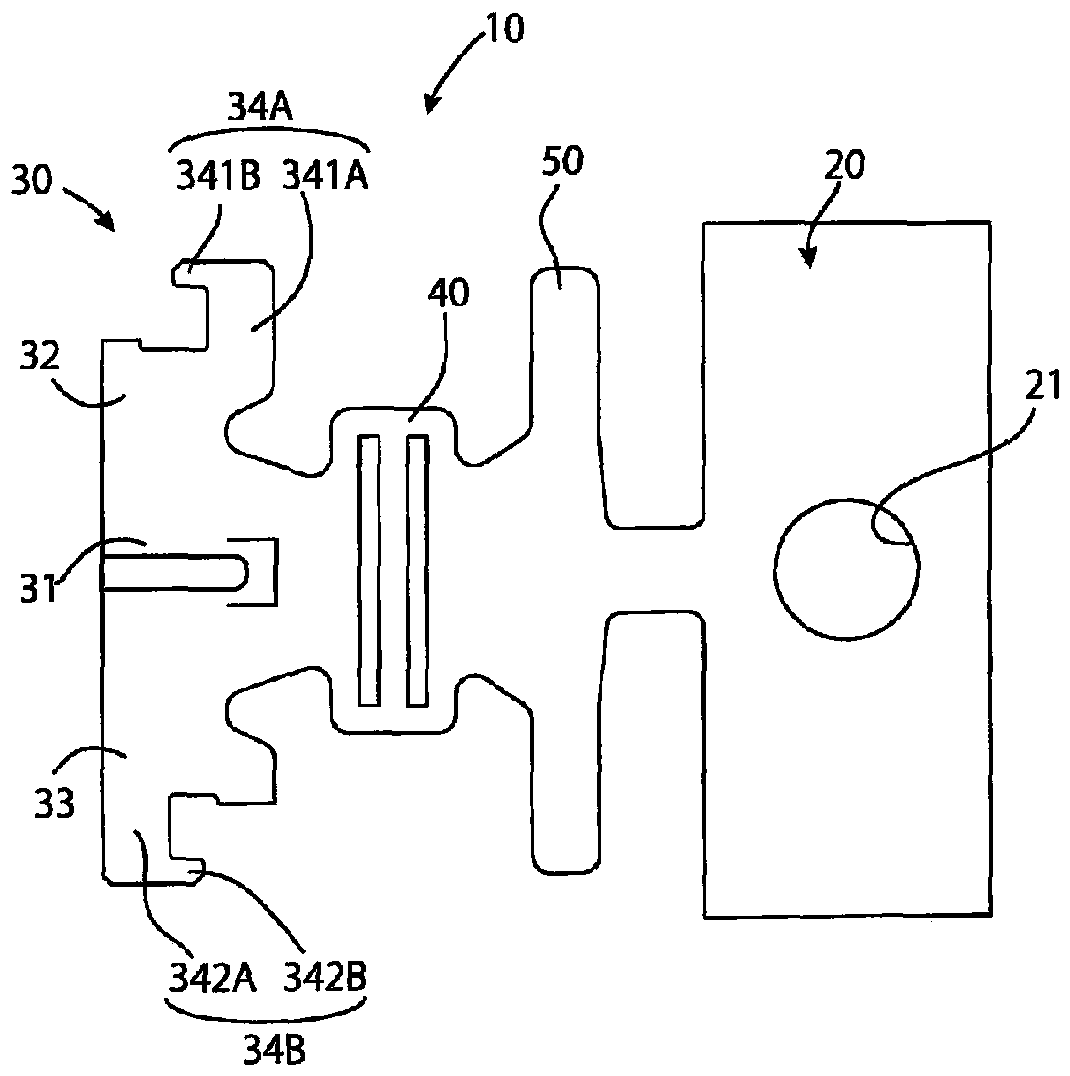

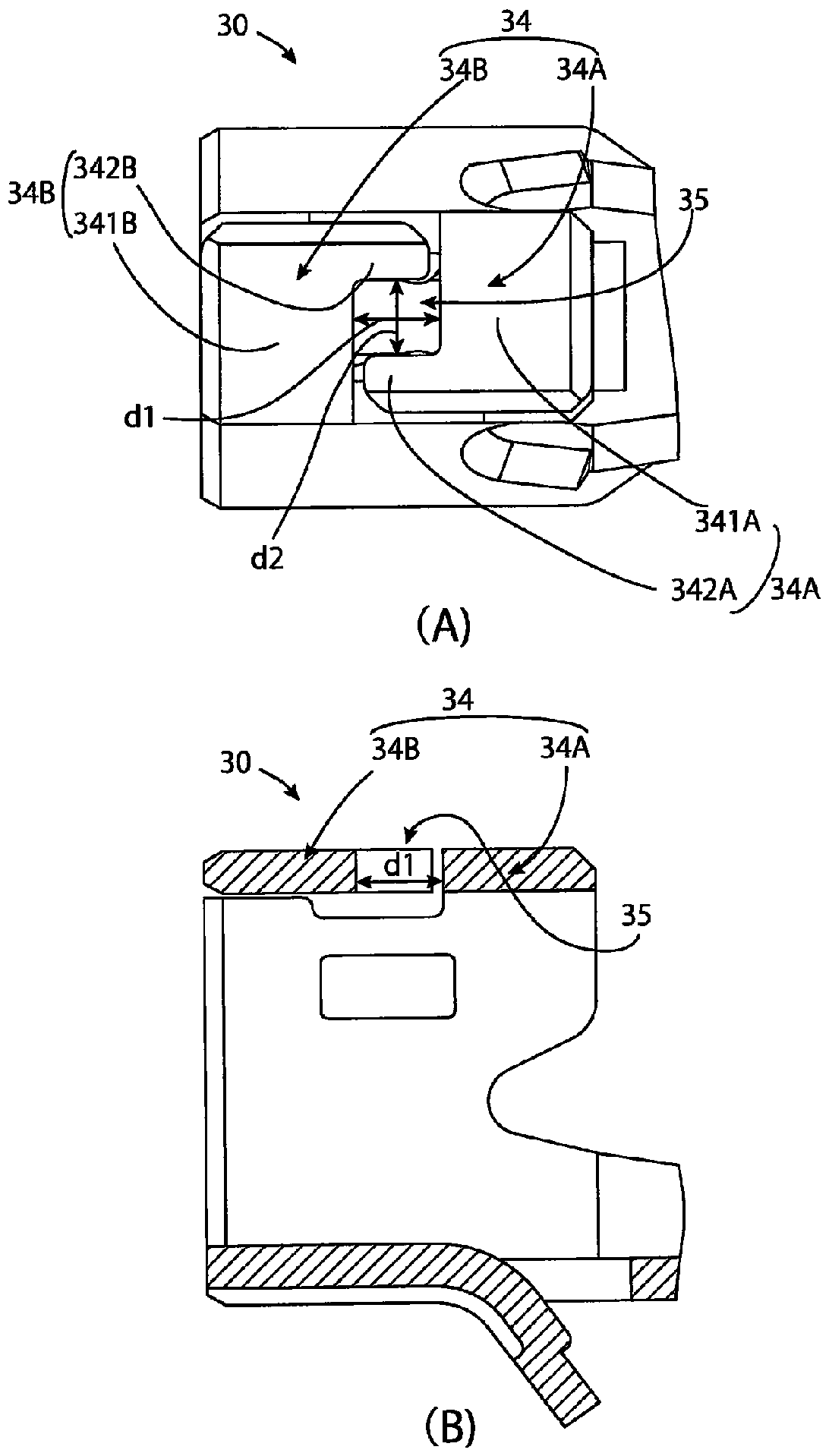

[0034] in addition, figure 2 is in figure 1 A three-sided view of the female contact in perspective view is shown in . here, figure 2 (A), (B) and (C) are top view, front view and side view, respectively.

[0035] In these figure 1 , figure 2 The female mold contact 10 shown is crimped connected with wires (not shown), and in figure 1 , figure 2 In , the female contact is shown in the shape before wire crimping.

[0036] And, in figure 1 , figure 2 The female contact 10 is shown with a bracket 20 attached thereto. figure 1 , figure 2 The bracket 20 is shown as a portion corresponding to one female contact, and actually, the bracket 20 has a long-dimensioned strip shape. Furthermore, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com