Machining device of lens and machining method thereof

A technology of processing equipment and processing methods, applied to other household appliances, optical components, household appliances, etc., can solve the problem of inability to ensure the uniformity of 4V photo-curing glue application, the lack of thickness uniformity, and the inability to apply large-scale continuous Production and other problems, to achieve the effect of ensuring the amount of glue, reducing losses, and reducing scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

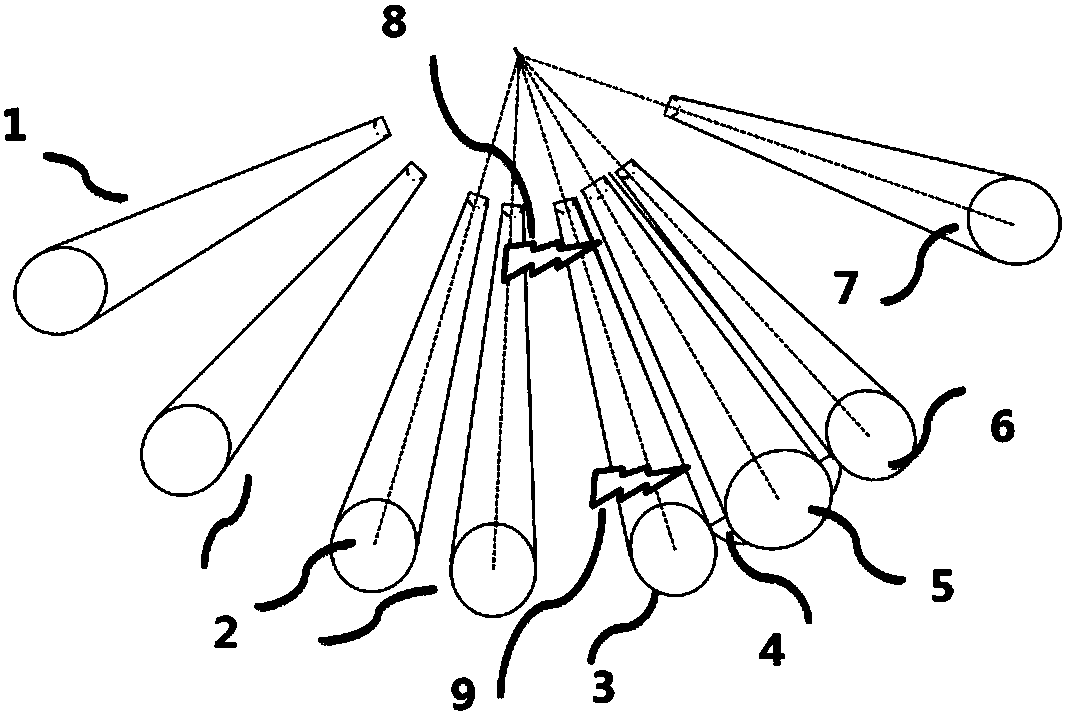

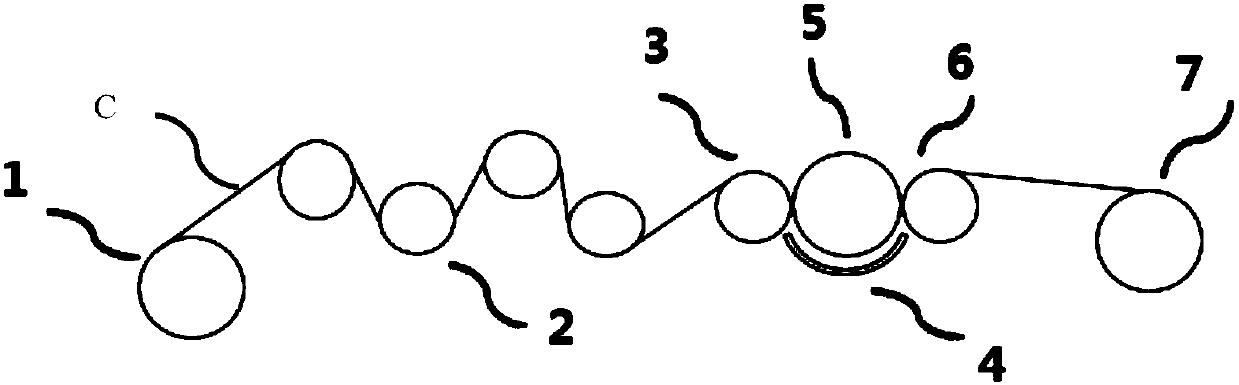

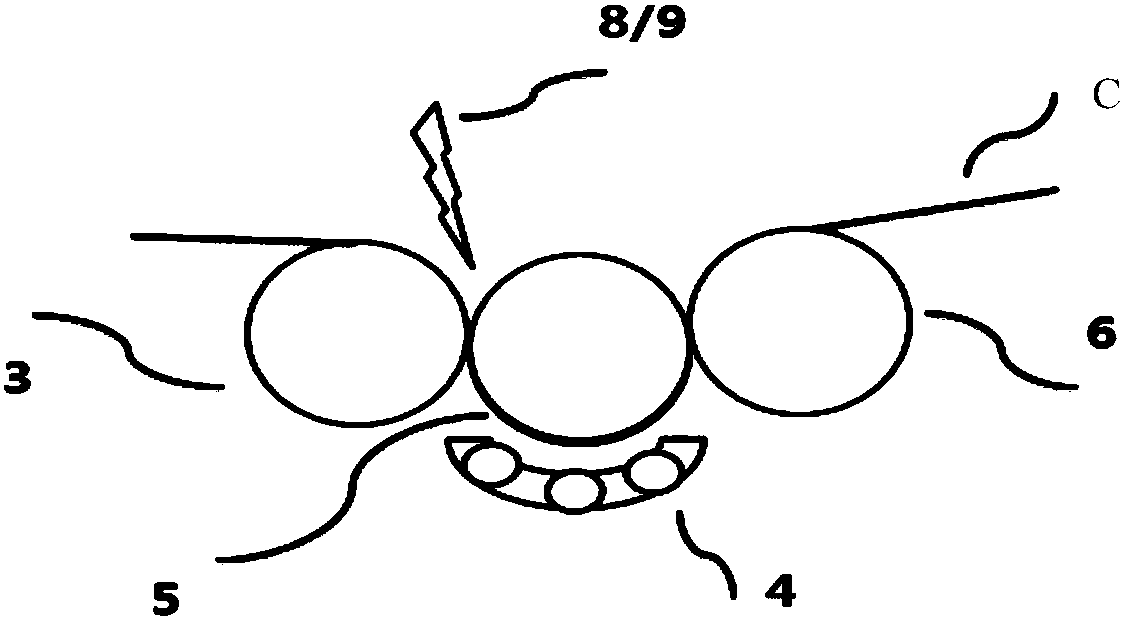

[0039] figure 1 It is a three-dimensional schematic diagram of the overall structure of the production equipment of the present invention; figure 2 It is a schematic plan view of the overall structure of the production equipment of the present invention; image 3 It is a schematic diagram of the local installation positions of the mirror roller, the structure roller and the curing mechanism of the present invention. Such as Figure 1 to Figure 3 As shown, the present invention provides a lens processing equipment. The production equipment mainly includes a conical roller linkage assembly. 2. The mirror roller 3, the structure roller 5 and the receiving roller 7, each tapered roller in the said tapered roller linkage assembly can perform a circular motion around its connecting end as the center. The surface of the mirror roller 3 is electroplated with a hard metal coating, and the surface of the structural roller 5 is provided with an annular groove structure. The producti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com