A splash-proof adjustable plug

An adjustable and splash-proof technology, applied in the mechanical field, can solve the problems of splashing, difficulty, waste, etc., and achieve the effects of expanding the adjustment range, preventing accidental injuries, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

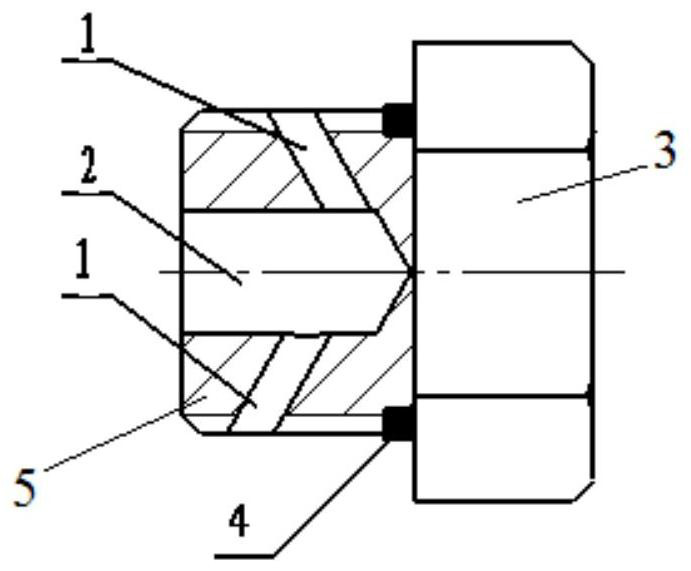

[0033] refer to figure 1 , a screw 5 and head 3 fixedly connected by a splash-proof adjustable plug, the head is an outer hexagonal head; a blind hole 2 is arranged on the screw 5 along the axial direction, and then the screw 5 radially approaches the inner hexagon The position of the end face is respectively processed with two circular oil discharge holes 1 arranged in a staggered arrangement. The included angle, the oil drain hole 1 is set obliquely, and one end of the connection between the oil drain hole 1 and the blind hole 3 is defined as the oil drain hole inlet, and the other end is defined as the oil drain hole outlet, and the distance between the oil outlet and the head 3 is greater than that of the drain hole. The distance between the entrance of the oil hole and the head 3, the axial positions of the two oil discharge holes 1 are at least the distance of the oil discharge hole;

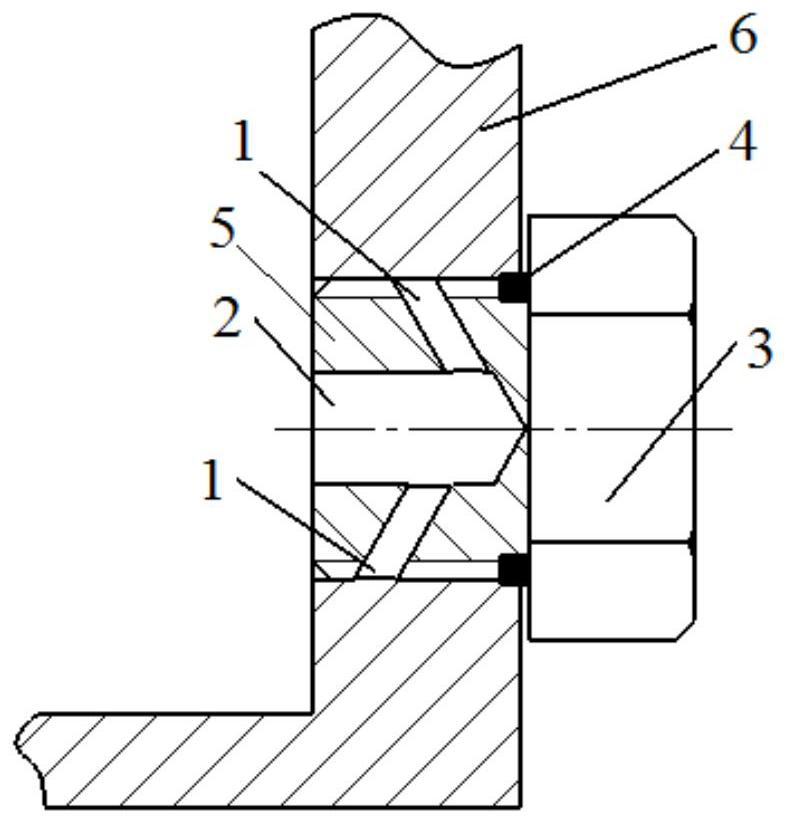

[0034] Plug seal with controllable discharge state such as figure 2 As shown, when ...

Embodiment 2

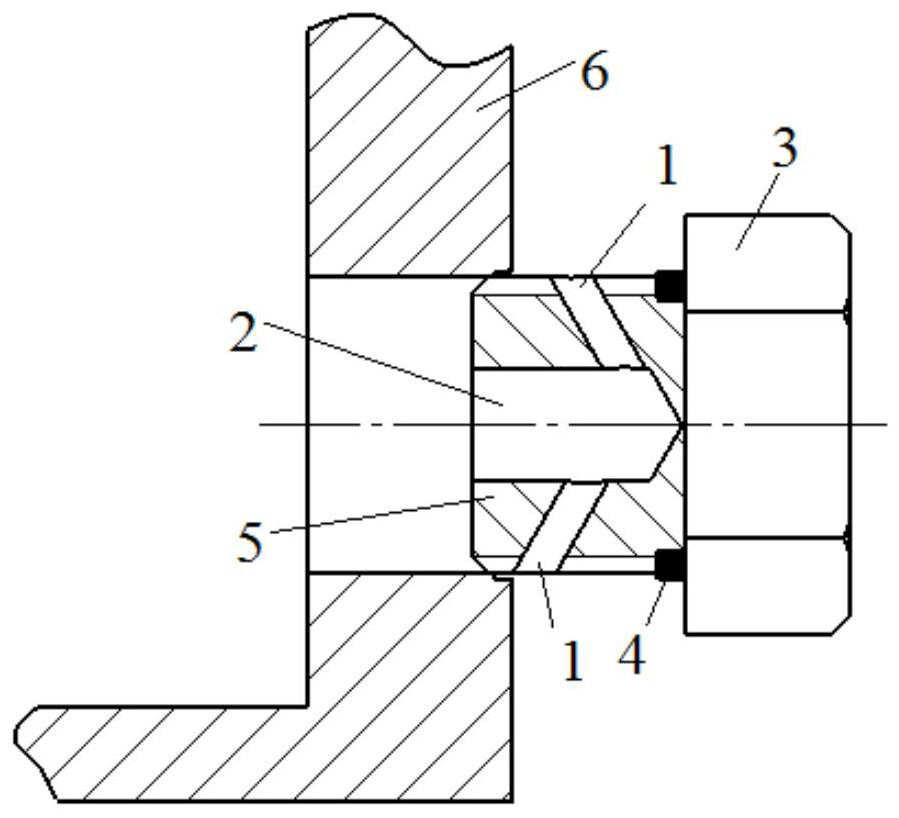

[0037] refer to Figure 4 The difference between this embodiment and Embodiment 1 is that the screw 5 is provided with 6 oil discharge holes 1 arranged in a staggered arrangement, and the outlet ends of the oil discharge holes 1 located on the same side of the screw 5 are located on the same straight line.

Embodiment 3

[0039] The difference between this embodiment and Embodiment 1 is that several groups of oil discharge holes 1 can be provided on the screw 5 along the circumferential direction, and the outlets of the same group of oil discharge holes 1 are located on the same circumference, so that when the screw is unscrewed, the flow rate can be increased.

[0040] The present invention can realize following function:

[0041] 1. The discharge flow and discharge volume can be controlled: the flow rate can be controlled by adjusting the screw-out length of the plug; when a certain amount of liquid is discharged for a certain period of time or a sufficient amount of liquid, the liquid can be continuously discharged by tightening the plug to block the discharge, so as to realize the precise control of the discharge of the liquid; When a large flow rate is required for complete drainage, the plug can be directly unscrewed completely for quick discharge.

[0042] 2. Prevent splashing: when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com