Process for ammonia dehydration in acrylonitrile production

A production process, the technology of acrylonitrile, applied in the field of ammonia dehydration, can solve the problems of heavy workload of operators, large amount of ammonia, and reduction of device load, etc., and achieve the effect of improving evaporation efficiency, reducing ammonia loss, and reducing ammonia loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

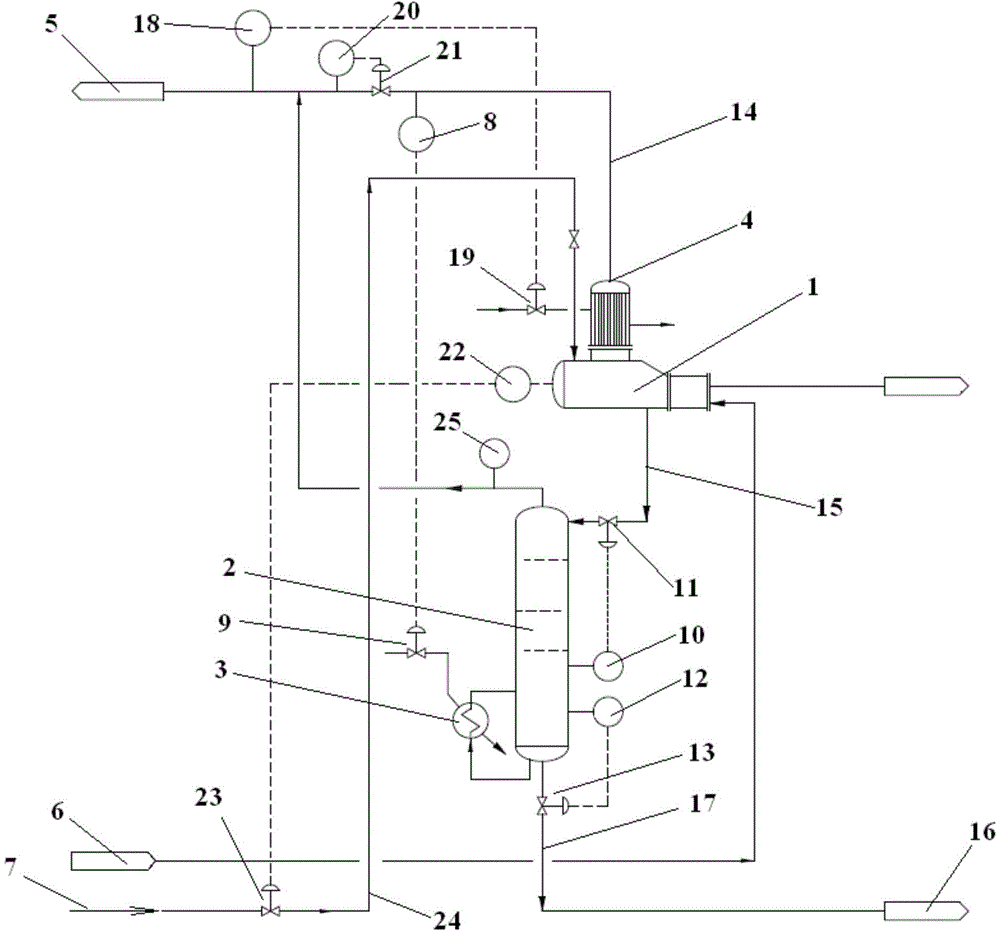

[0019] In the production process of acrylonitrile, the liquid ammonia and liquid propylene are evaporated and sent to the reactor for reaction, and the generated gas (acrylonitrile, etc.) is sent to the cooler and the quenching tower for cooling, and then sent to the absorption tower for water absorption, and finally sent to the refining Unit purification processing. According to the requirements of the process, it is more beneficial when the temperature of the absorption water in the absorption tower is lower. Therefore, this part of water is sent to the ammonia evaporator to cool down and provide the heat required by the ammonia evaporator. Specifically, the absorption tower is divided into three sections. The temperature of the water discharged from the upper section is 30°C. This part of the water is sent to the ammonia evaporator to cool down to, for example, 4°C. The heat; and the low-temperature water (for example, water cooled to 4°C) from the ammonia evaporator is sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com