lng ship conveying refrigeration system and refrigeration conveying method

A refrigeration system and ship technology, applied in ship accessories, transportation and packaging, ships, etc., can solve the problems of volatilization and LNG loss, and achieve the effect of avoiding heat volatilization and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

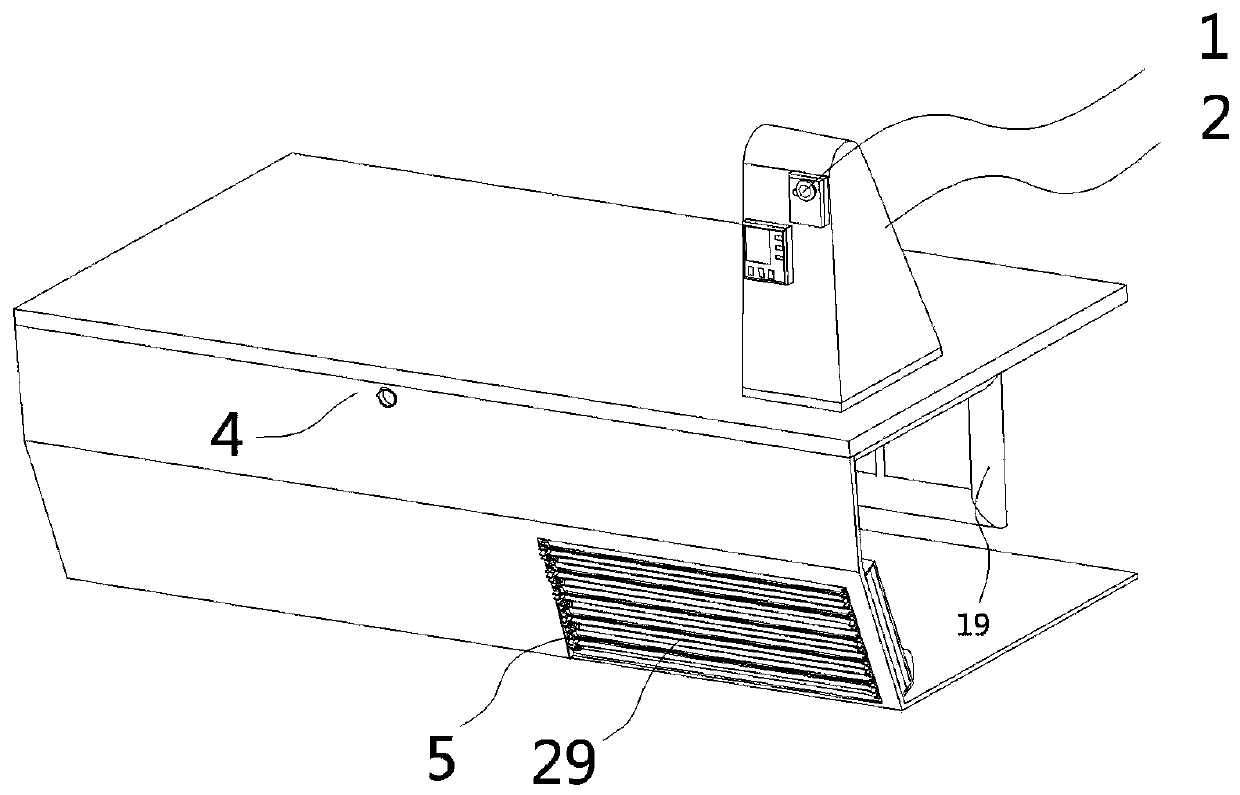

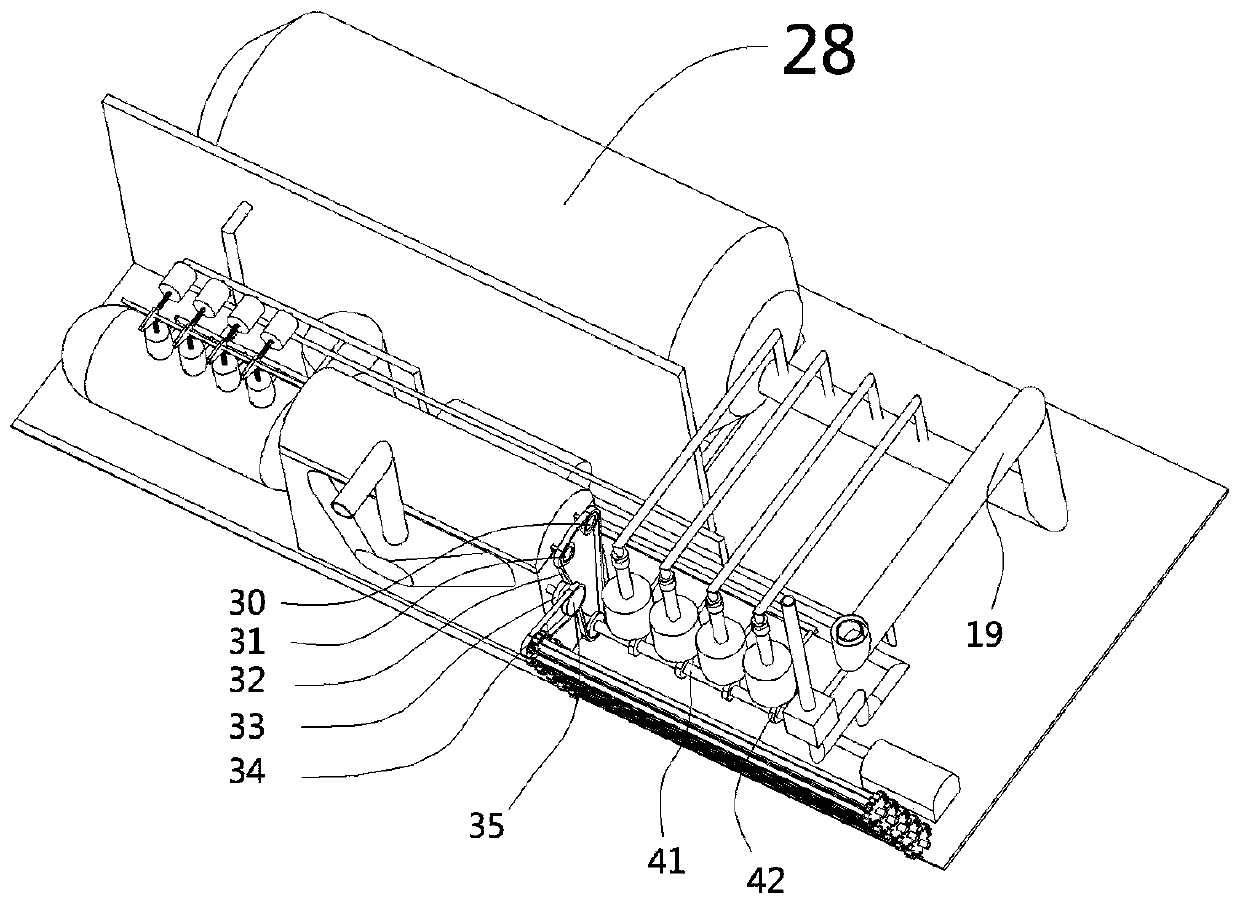

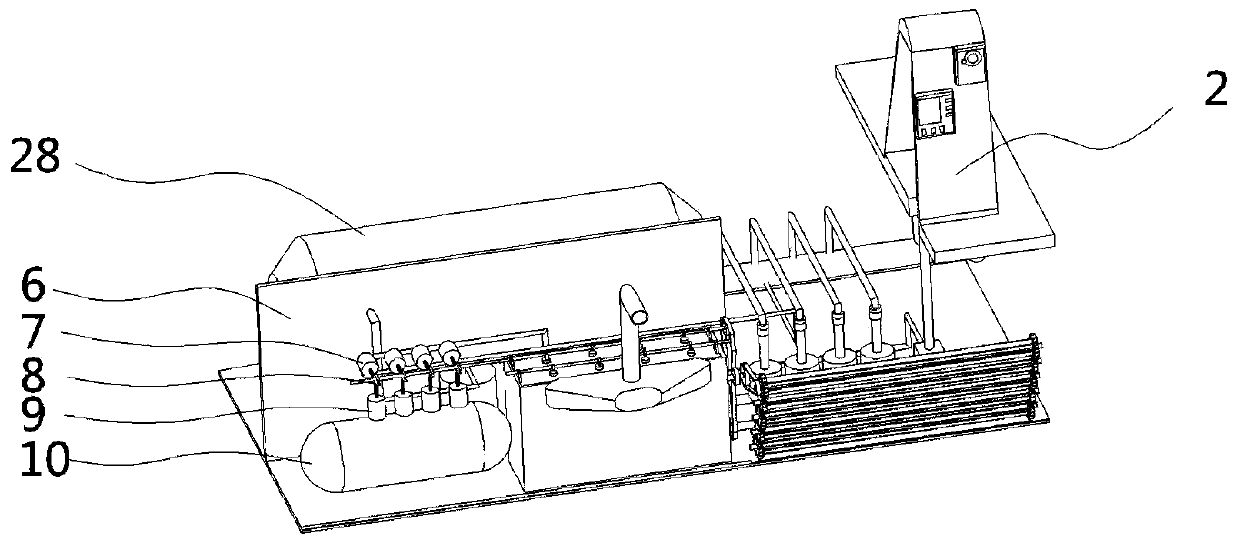

[0027] As shown in the figure, the LNG ship material delivery refrigeration system includes an LNG storage tank 28, a ship internal combustion engine 13 and a nitrogen storage tank 23. The ship internal combustion engine 13 is connected with an internal combustion engine exhaust port 4, and the LNG storage tank 28 is arranged in On the ship, the LNG storage tank 28 is connected with an LNG delivery inner pipe 40, and the outer periphery of the LNG delivery inner pipe 40 is also wrapped with an outer protection tube 19, which forms a double-layer tube, and an insulation layer is also installed on the outer protection tube 19 A BOG output pipe 27 is also connected between the LNG storage tank 28 and the BOG storage tank 10, and a liquid nitrogen storage tank 24 is installed below the nitrogen storage tank 23;

[0028] The first pulley 30, the second pulley 31, the auxiliary pulley 35 and the main shaft rod 41 are respectively installed on the internal combustion engine 13 of the ...

Embodiment 2

[0039] As shown in the figure, the LNG ship material delivery refrigeration system includes an LNG storage tank 28, a ship internal combustion engine 13 and a nitrogen storage tank 23. The ship internal combustion engine 13 is connected with an internal combustion engine exhaust port 4, and the LNG storage tank 28 is arranged in On the ship, the LNG storage tank 28 is connected with an LNG delivery inner pipe 40, and the outer periphery of the LNG delivery inner pipe 40 is also wrapped with an outer protection tube 19, which forms a double-layer tube, and an insulation layer is also installed on the outer protection tube 19 A BOG output pipe 27 is also connected between the LNG storage tank 28 and the BOG storage tank 10, and a liquid nitrogen storage tank 24 is installed below the nitrogen storage tank 23;

[0040] The first pulley 30, the second pulley 31, the auxiliary pulley 35 and the main shaft rod 41 are respectively installed on the internal combustion engine 13 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com