Packaging equipment for capacitor production

A technology for packaging equipment and capacitors, applied in the field of capacitors, can solve the problems of electrolyte injection, electrolyte volatilization, inconvenience in use, etc., to achieve good cooling effect, prevent heat volatilization, and good electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

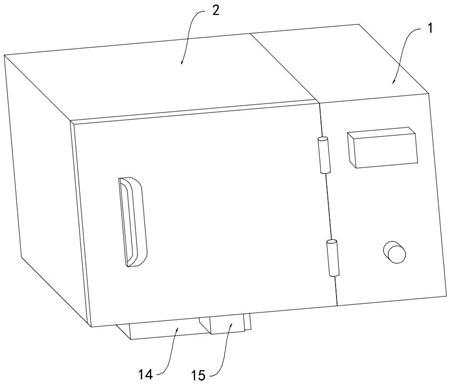

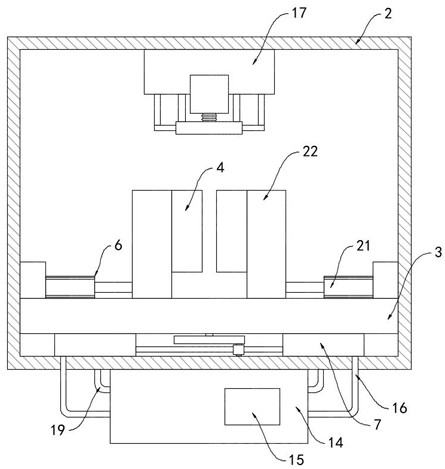

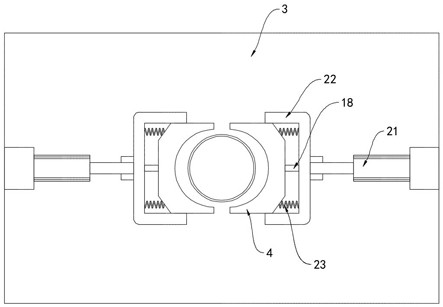

[0033] Such as Figure 1-7 As shown, a kind of packaging equipment for capacitor production includes a control box 1, a refrigeration packaging box 2 and a filler 17. A power supply is installed in the control box 1, and a switch for controlling the opening and closing of the power supply is arranged on the outer wall. The filler 17 is installed On the inner top surface of the refrigeration packing box 2, a horizontal plate 3 is installed in the refrigeration packing box 2, and two fixing blocks 4 are arranged on the As for the fixing mechanism 6 for fixing the capacitor, a cooling mechanism 7 for cooling the capacitor is provided under the horizontal plate 3;

[0034] Further, the cooling mechanism 7 includes a turntable 8 and two liquid inlet cylinders 9, and a piston 10 is sealed and slid in the two liquid inlet cylinders 9, and the two pistons 10 are fixed by a connecting rod 11, and the connecting rod 11 is fixedly connected with a The swing frame 12 is slidingly connect...

Embodiment 2

[0044] Such as Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that the cavity 24 is filled with low-temperature molten salt, and the liquid level of the low-temperature molten salt is lower than the rack 26. In this embodiment, pyrrole is used for the low-temperature molten salt. Salt ion type, not easy to volatilize, and has poor electrical conductivity at low temperature, and good electrical conductivity at high temperature. The upper surface of the horizontal plate 3 is equipped with an electrothermal difference sheet 31, which is made of semiconductor material. , the heat will be transferred from the hot surface to the cold surface, the cold surface of the electrothermal plate 31 faces upwards, the hot surface is in contact with the upper surface of the horizontal plate 3, and the positive and negative poles of the electrothermal plate 31 are electrically connected to the power supply through a low-temperature molten salt .

[0045] In this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com