Environment-friendly flame retardant for wood and preparation method and application thereof

A flame retardant and environmental protection technology, applied in the field of environmental protection flame retardants for wood and their preparation, can solve problems such as human health effects, and achieve the effects of avoiding heat transfer to, improving compatibility, and enhancing polymerization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

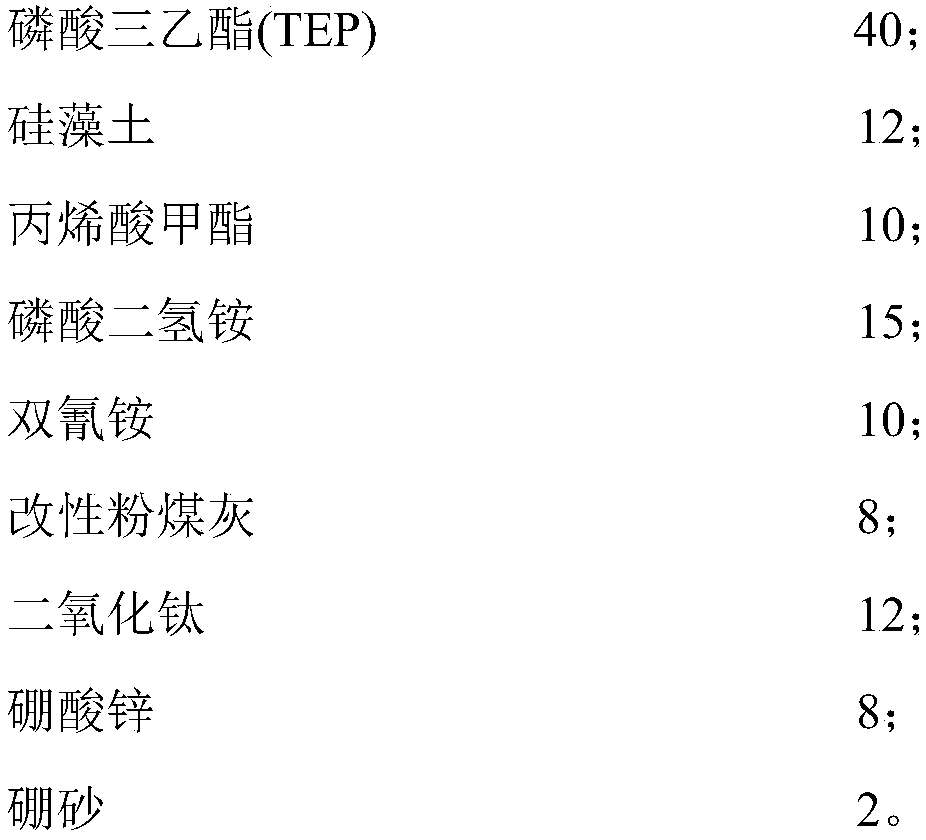

Image

Examples

Embodiment 1

[0040] The environment-friendly flame retardant for wood of this embodiment, in parts by weight, its raw materials include the following components:

[0041] Triethyl phosphate: 30 parts,

[0042] Polyvinyl alcohol: 25 parts,

[0043] Dextrin: 5 parts,

[0044] Ethyl acetate: 5 parts,

[0045] Magnesium chloride: 0.2 parts.

[0046] The preparation method of above-mentioned environment-friendly flame retardant for wood, its step comprises:

[0047] (1) Triethyl phosphate, polyvinyl alcohol and dextrin were pre-mixed uniformly in the reactor, the temperature of the reactor was controlled at 120°C, and the pressure of the reactor was controlled at 1.5MPa to prepare the premix;

[0048] (2) Pour the premix, ethyl acetate and magnesium chloride prepared in step (1) into a stirrer, and the temperature of the stirrer is controlled at 70°C to obtain an environmentally friendly flame retardant for wood.

Embodiment 2

[0050] The environment-friendly flame retardant for wood of this embodiment, in parts by weight, its raw materials include the following components:

[0051] Triethyl phosphate: 50 parts,

[0052] Polyvinyl alcohol: 25 parts,

[0053] Dextrin: 5 parts,

[0054] Ethyl acetate: 10 parts,

[0055] Magnesium chloride: 0.6 parts.

[0056] The preparation method of above-mentioned environment-friendly flame retardant for wood, its step comprises:

[0057] (1) Triethyl phosphate, polyvinyl alcohol and dextrin were pre-mixed uniformly in the reactor, the temperature of the reactor was controlled at 150° C., and the pressure of the reactor was controlled at 1.8 MPa to obtain a premix;

[0058] (2) Pour the premix, ethyl acetate and magnesium chloride prepared in step (1) into a stirrer, and the temperature of the stirrer is controlled at 80°C to obtain an environmentally friendly flame retardant for wood.

Embodiment 3

[0060] The environment-friendly flame retardant for wood of this embodiment, in parts by weight, its raw materials include the following components:

[0061] Triethyl phosphate: 32 parts,

[0062] Polyvinyl alcohol: 20 parts,

[0063] Dextrin: 10 parts,

[0064] Ethyl acetate: 6 parts,

[0065] Magnesium chloride: 0.3 parts.

[0066] The preparation method of above-mentioned environment-friendly flame retardant for wood, its step comprises:

[0067] (1) Triethyl phosphate, polyvinyl alcohol and dextrin were pre-mixed uniformly in the reactor, the temperature of the reactor was controlled at 125° C., and the pressure of the reactor was controlled at 1.6 MPa to prepare a premix;

[0068] (2) Pour the premix, ethyl acetate and magnesium chloride prepared in step (1) into a stirrer, and the temperature of the stirrer is controlled at 72° C. to obtain an environmentally friendly flame retardant for wood.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com