Wind-driven retrograde motion driving mechanism

A technology of driving mechanism and actuator, applied in the field of machinery, can solve the problem of less energy-saving improvement technology and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

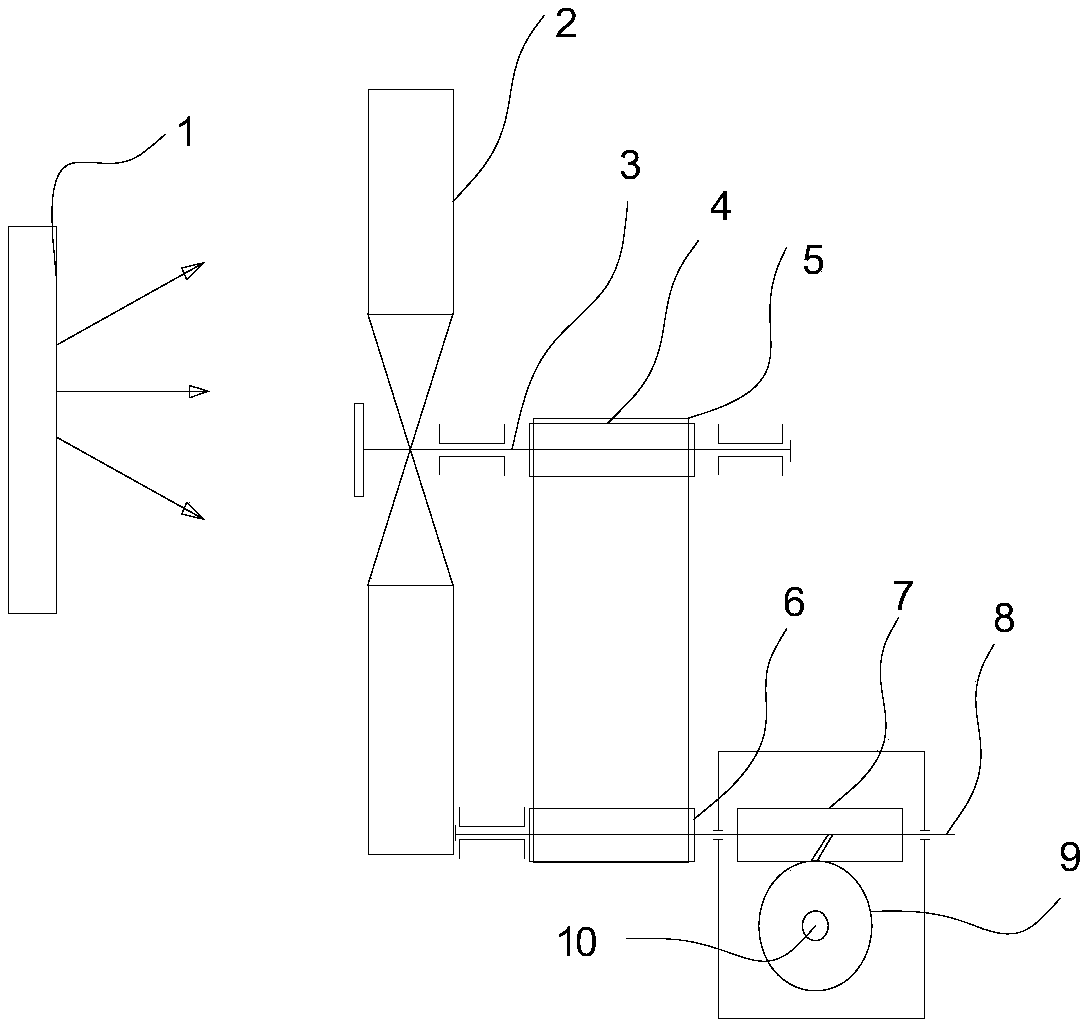

[0028] Such as figure 1 As shown, the driving mechanism includes fan blade 2, fan shaft 3, transmission device, reducer and actuator, fan blade 2 is fixedly connected to fan shaft 3, fan shaft 3 is connected with transmission device, and fan shaft 3 drives the transmission device to exert force on The speed reducer, the shaft of the speed reducer is connected to the actuator, and the power source of the driving mechanism is natural wind or artificial wind.

[0029] The driving mechanism is connected to the unpowered trolley, and the power source can be a fan or other mechanism, and the self-running of the driving mechanism can be realized by turning on the fan. It faces the fan blade in front of the wind force, and the wind acts on the fan blade to generate thrust on the fan blade 2, the fan blade rotates, the fan blade 2 is fixedly connected to the fan shaft, and the fan blade 2 drives the fan shaft 3 to rotate, and the fan shaft 3 To transmit the rotational force to the tra...

Embodiment 2

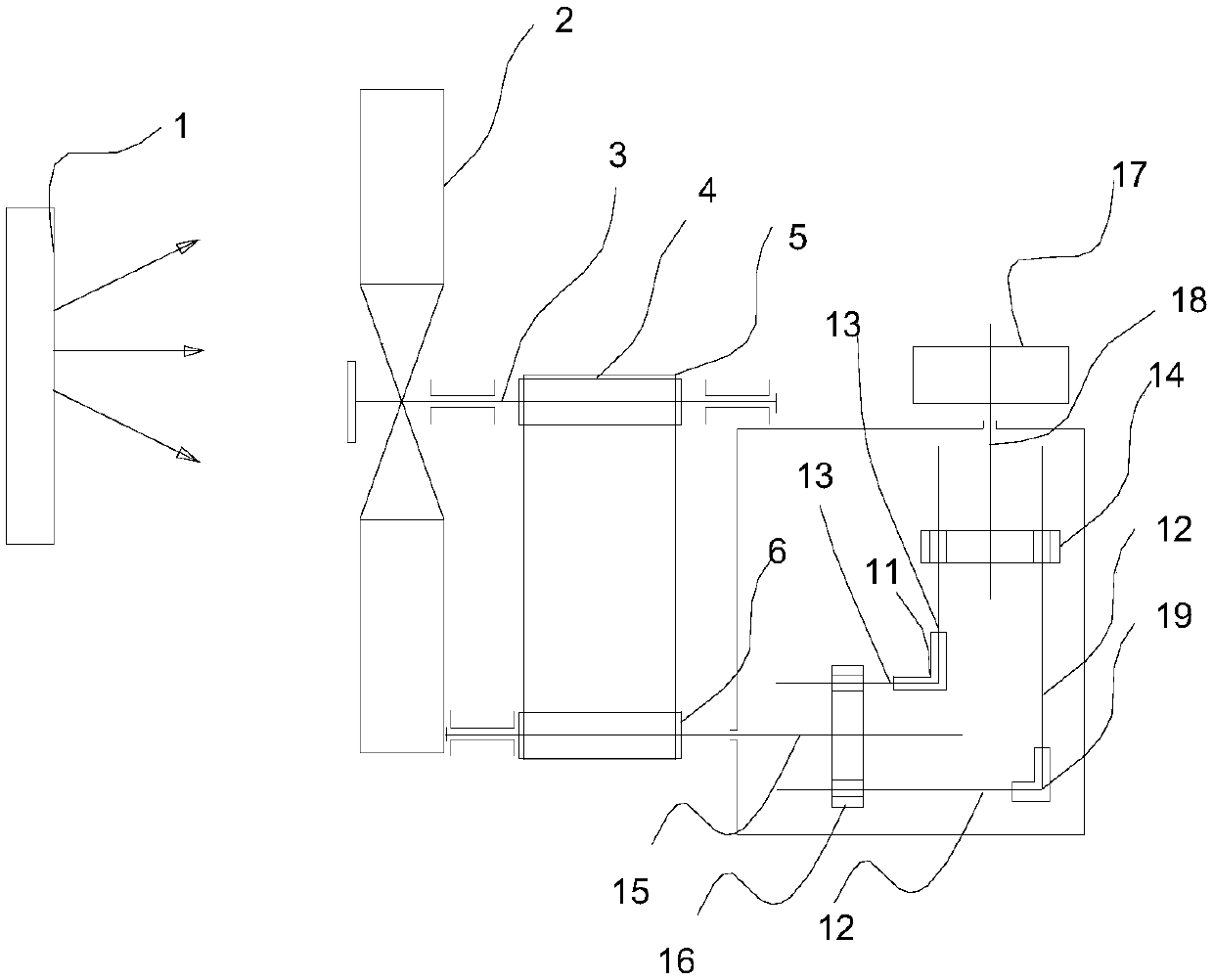

[0040] Such as figure 2 shown, with figure 1 Part of the structure is the same, and the driving mechanism of the specific embodiment 2 includes the fan blade 2, the fan shaft 3, the transmission device, the reducer and the actuator, the fan blade is fixedly connected to the fan shaft 3, the fan shaft 3 is connected to the transmission device, and the fan shaft 3 Drive the transmission device to apply force to the reducer, and the reducer shaft is connected to the actuator. The power source of the drive mechanism is natural wind or artificial wind, and the movement direction of the actuator is opposite to the direction of the wind force. The power source can consider choosing an electric fan. The executive structure is the wheel, which can be used as the rear wheel of the trolley. When the electric fan is turned on, the driving mechanism is driven by the wind to move forward, and the wheels move forward.

[0041] This mechanism can also be applied to outdoor scenes. When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com