Gear box vibration signal processing and analyzing method

A technology of vibration signal and analysis method, which is applied to the testing of measuring devices, instruments, and mechanical components, etc., and can solve problems such as inability to apply time domain, inability to track intermediate shafts, planetary gear shafts, and inability to obtain equal-angle sampling waveform data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail now in conjunction with accompanying drawing.

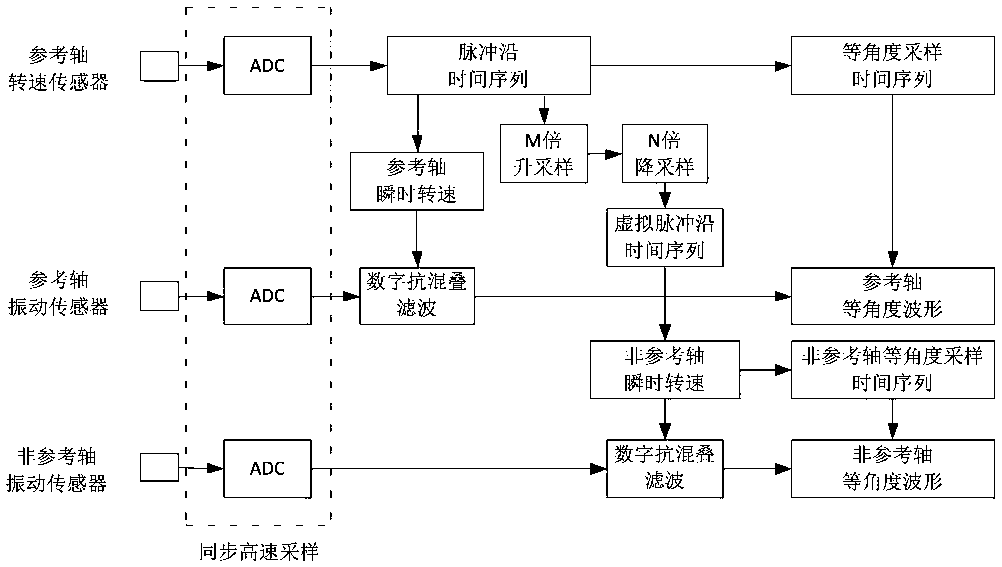

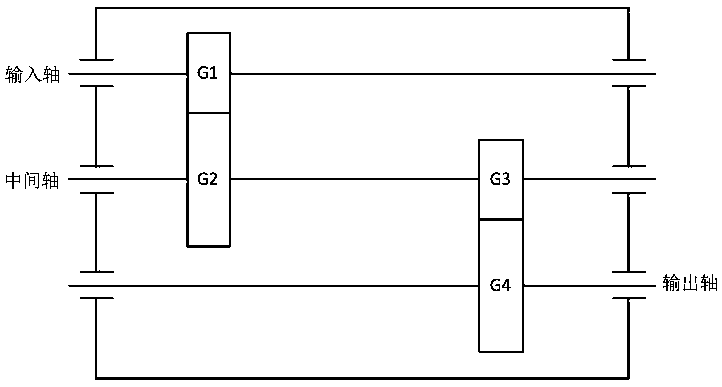

[0026] Such as figure 1 As shown, first, use a multi-channel high-speed synchronous acquisition card to synchronously acquire the reference shaft (such as the input shaft of the planetary gearbox), the reference shaft vibration and the vibration signals of other non-reference shafts (such as the planetary gear shaft, sun gear shaft, output shaft, etc.) . The speed measurement sensor can use an eddy current sensor or a photoelectric sensor. For the use of an eddy current sensor, a speed measuring gear disc or a key phase slot needs to be installed on the reference shaft, and an ordinary acceleration sensor can be used for the vibration signal.

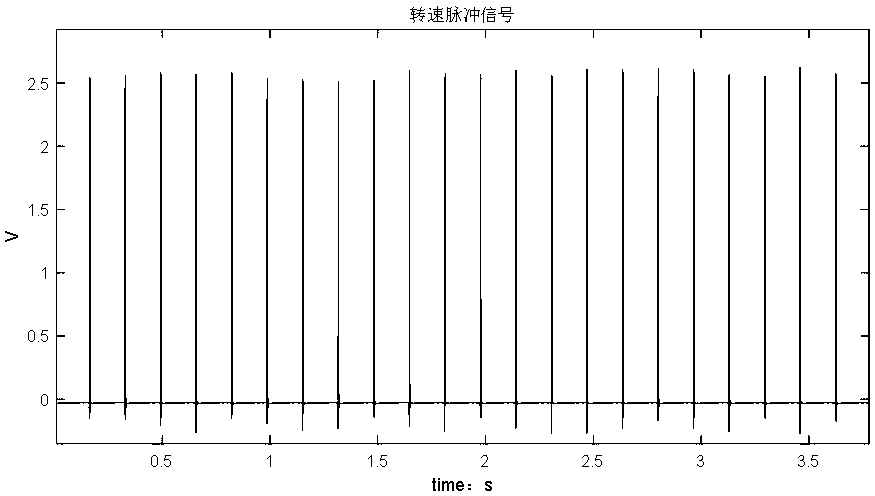

[0027] The speed pulse edge is identified by the speed signal, and the arrival time of each pulse edge is automatically calculated, and the instantaneous speed between each two pulses is calculated. At the same time, the pulse ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com