Spherical internal detector for detecting petroleum transmission pipeline leakage

An inner detector and oil pipeline technology, applied in the field of spherical inner detector, can solve the problems of high risk of blockage or even damage to the pipeline, high detection cost, large volume, etc., and achieve the effects of wide applicability, high detection sensitivity and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

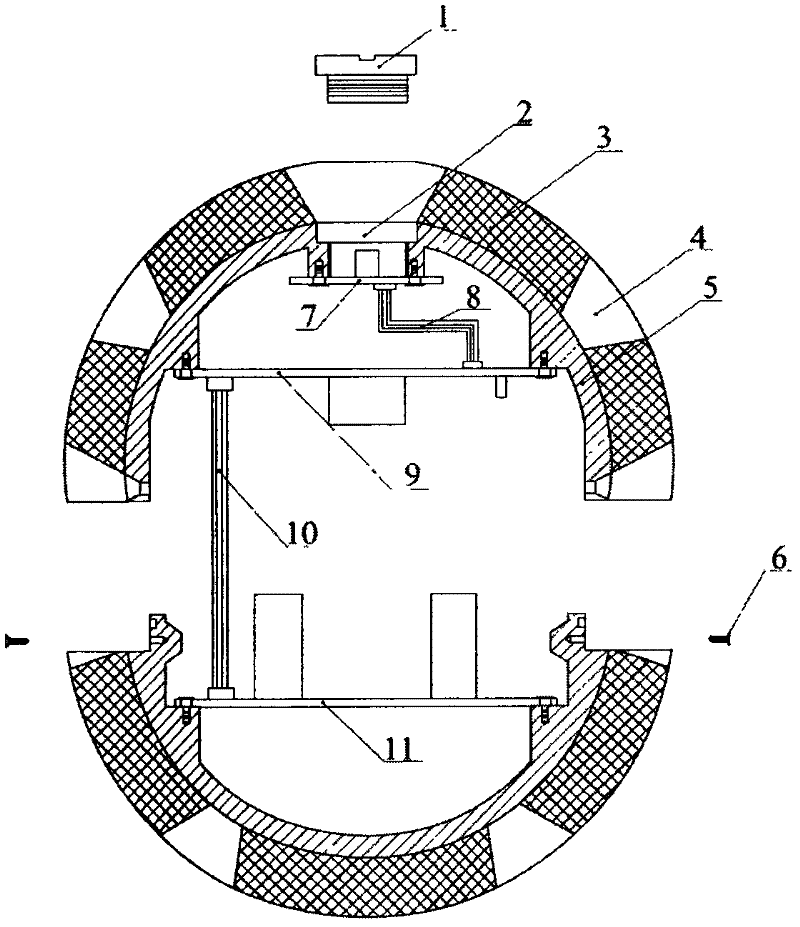

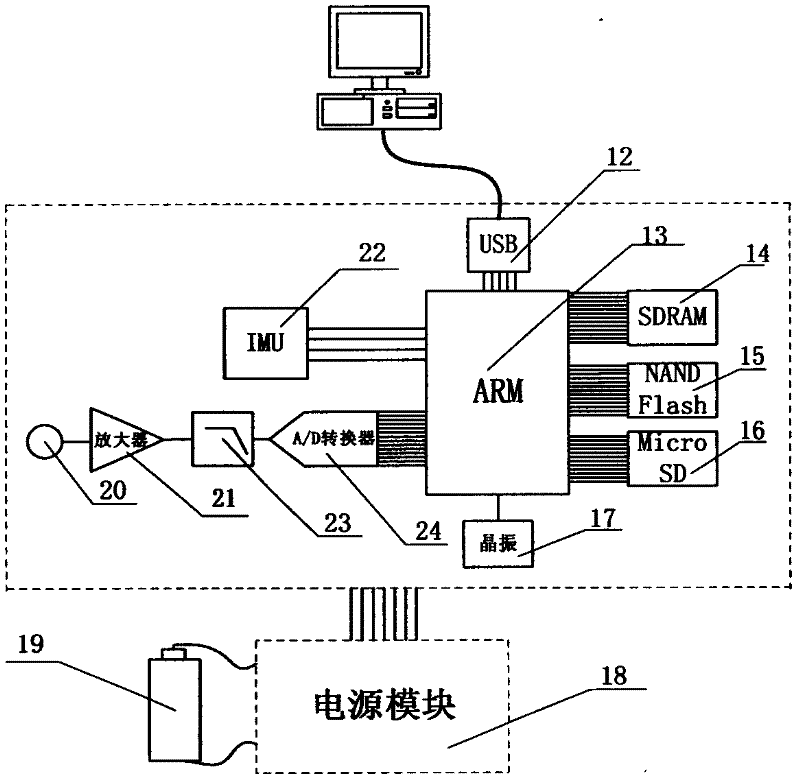

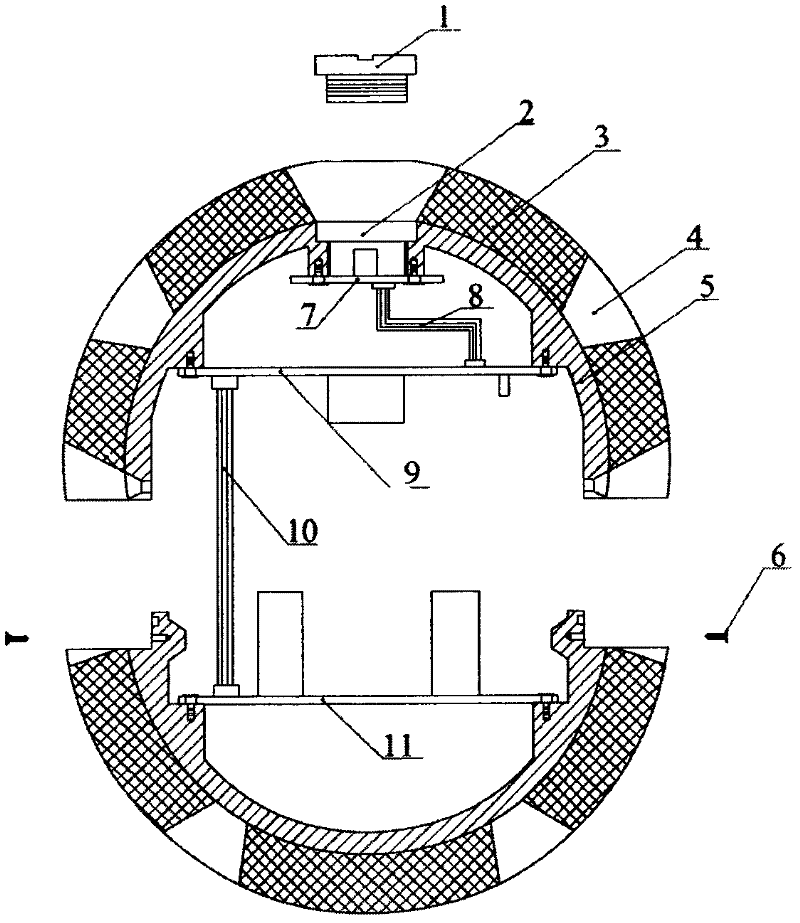

[0011] Attached below figure 1 And attached figure 2 The present invention is further described. figure 1 Middle 5 is the spherical pressure-bearing aluminum shell of the inner detector, which is composed of two hemispherical aluminum shells connected by slits and fastened by 3 to 6 M4*5 fastening screws 6. In the lower hemispherical aluminum shell The shell is provided with a groove for placing an O-shaped sealing ring. The two hemispherical aluminum shells form a radial seal. The outer diameter of the aluminum spherical shell is Φ100mm, the wall thickness is 8mm, and the design pressure is ≥5MPa; the polyurethane foam layer 3 is closely attached to the On the spherical pressure-bearing aluminum shell, the thickness of the foam layer is 30mm; a tapered hole 4 is set on the polyurethane foam layer. The large hole diameter of the tapered hole is Φ15mm, and the small hole diameter is Φ10mm. The top of the housing is provided with a threaded communication hole 2, the internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com