Driving control circuit for a great many of backlight partitions, and display device

A technology for driving control circuits and backlight partitions, applied to static indicators, instruments, etc., can solve the problems of high product cost, large number of driving ICs, complex manufacturing process, etc., and achieve a reduction in quantity, operability, and outstanding functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

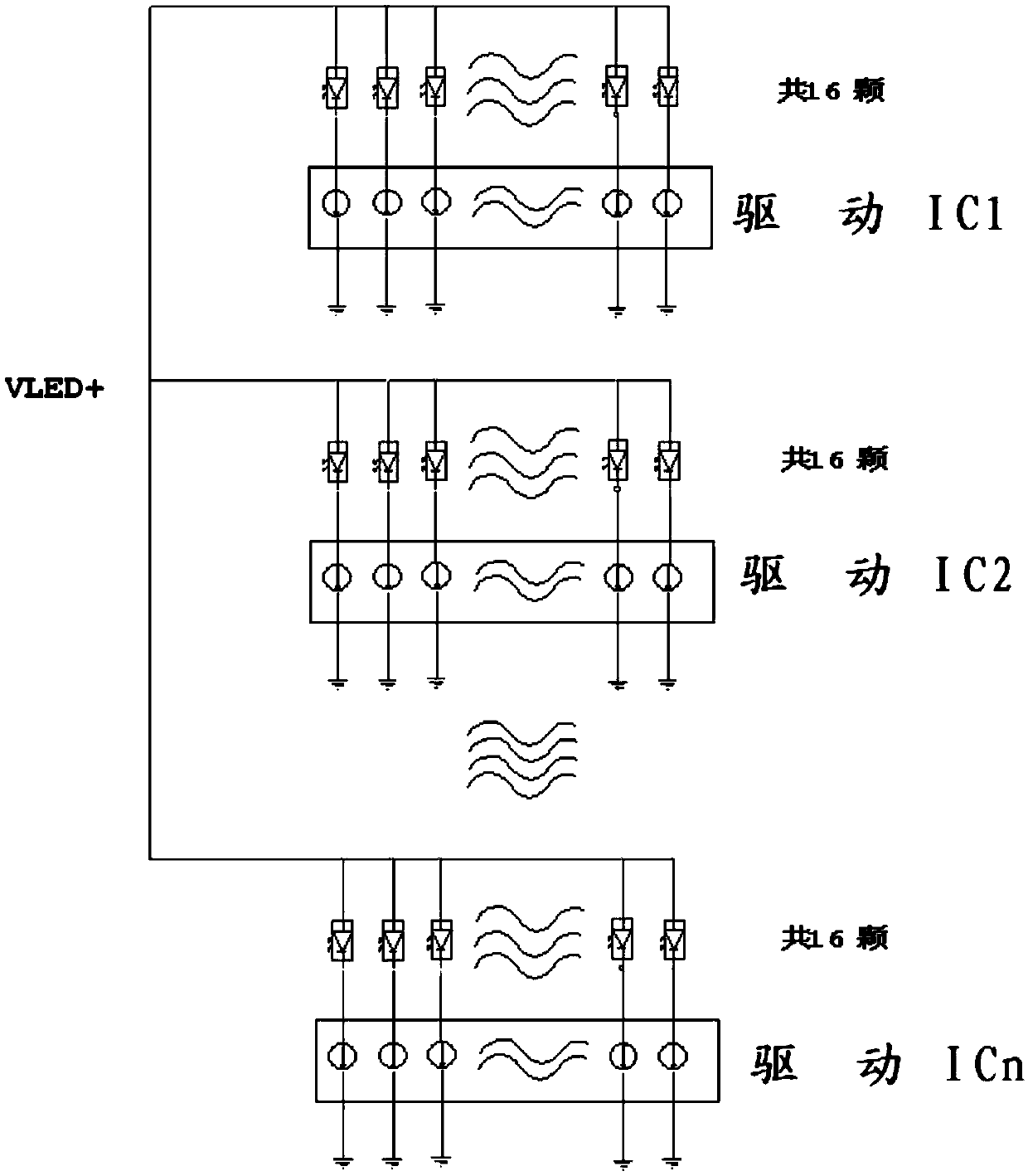

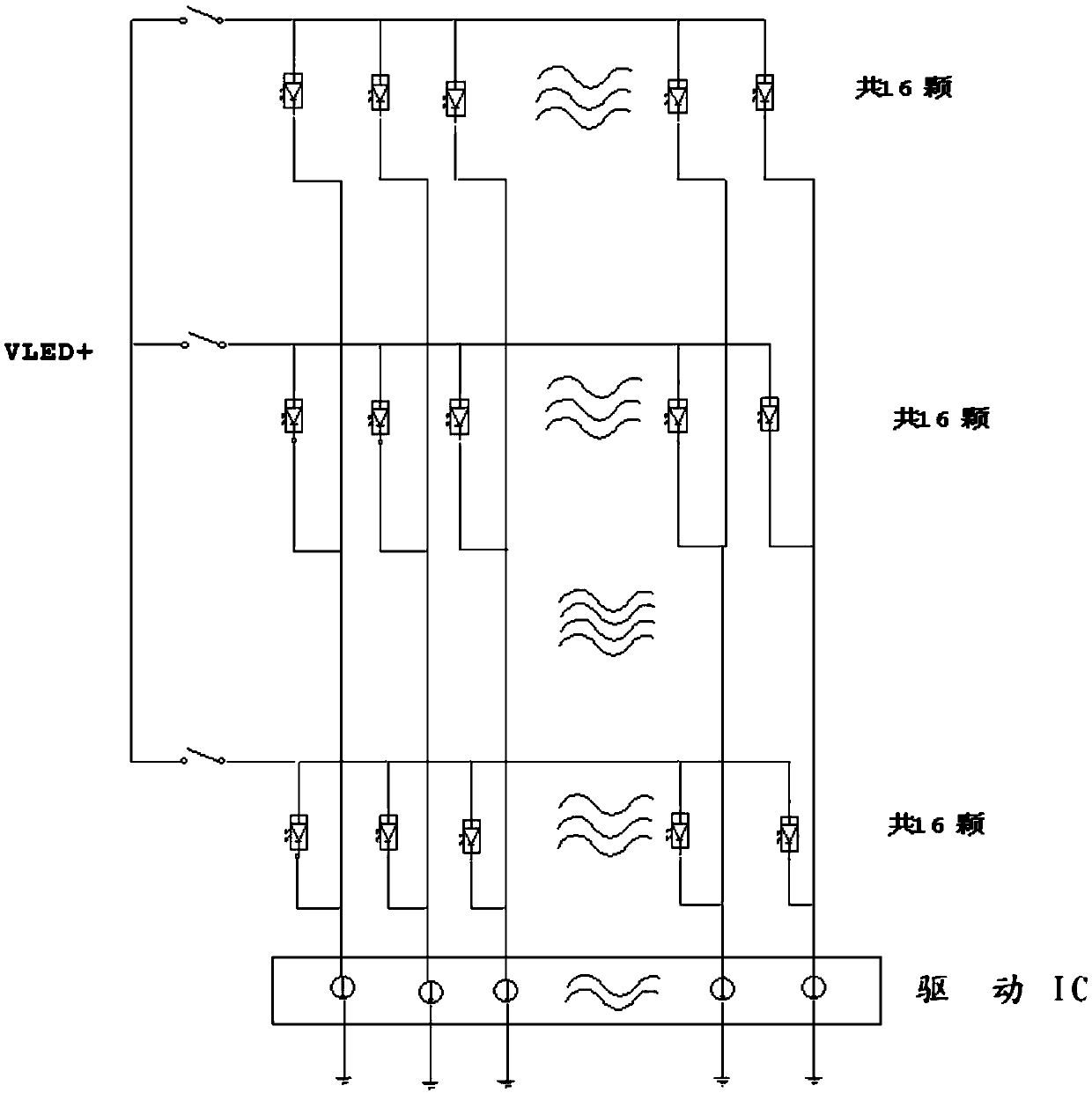

[0026] Such as Figure 3-Figure 5 As shown, a super multi-backlight partition driving control circuit includes multiple backlight sources, multiple drive ICs and multiple switch control devices. The multiple backlight sources are divided into multiple groups, and each group of backlight sources is connected in the form of rows and columns. And driven by the same driver IC, wherein the number of rows of each group of backlight is N, the number of columns of each group of backlight is the same as the number of driving channels of the driver IC, and each row of backlight is equipped with The switch control device, wherein each backlight source in each row of backlight sources is arranged between the output terminal of the row switch control device and each input terminal of the drive IC, and the switch control device is used to individually control the All the backlights of the row are turned on or off at the same time; in the same driving period T, the time for the switch contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com