Transformer iron yoke sheet insertion platform

A technology of transformers and iron yokes, applied in the manufacture of inductors/transformers/magnets, components of transformers/inductors, electrical components, etc., can solve the problems of increasing labor intensity, increasing operation time, and unable to guarantee product quality, etc. The effect of shortening the operation time, improving the production efficiency and reducing the labor intensity of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

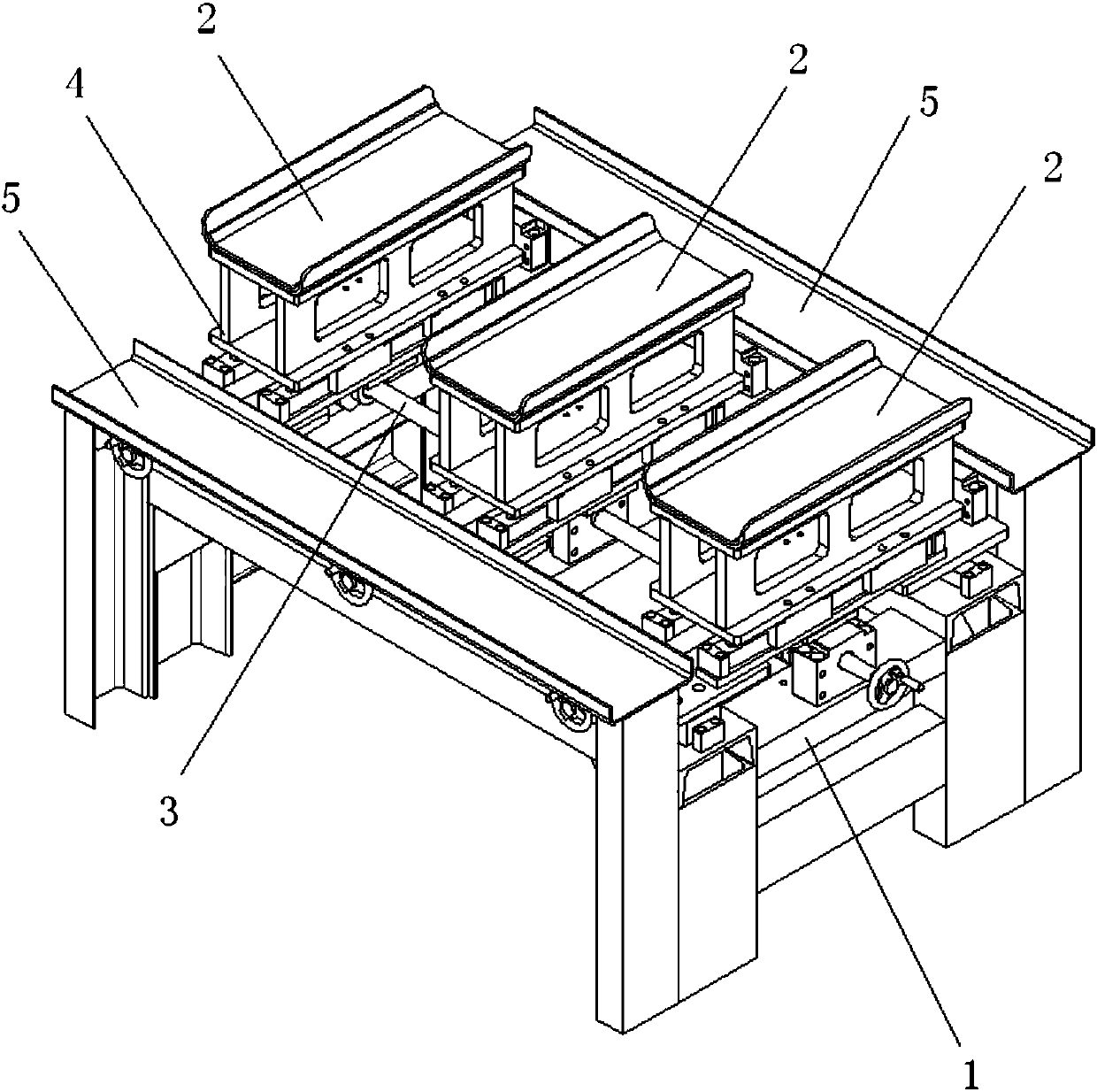

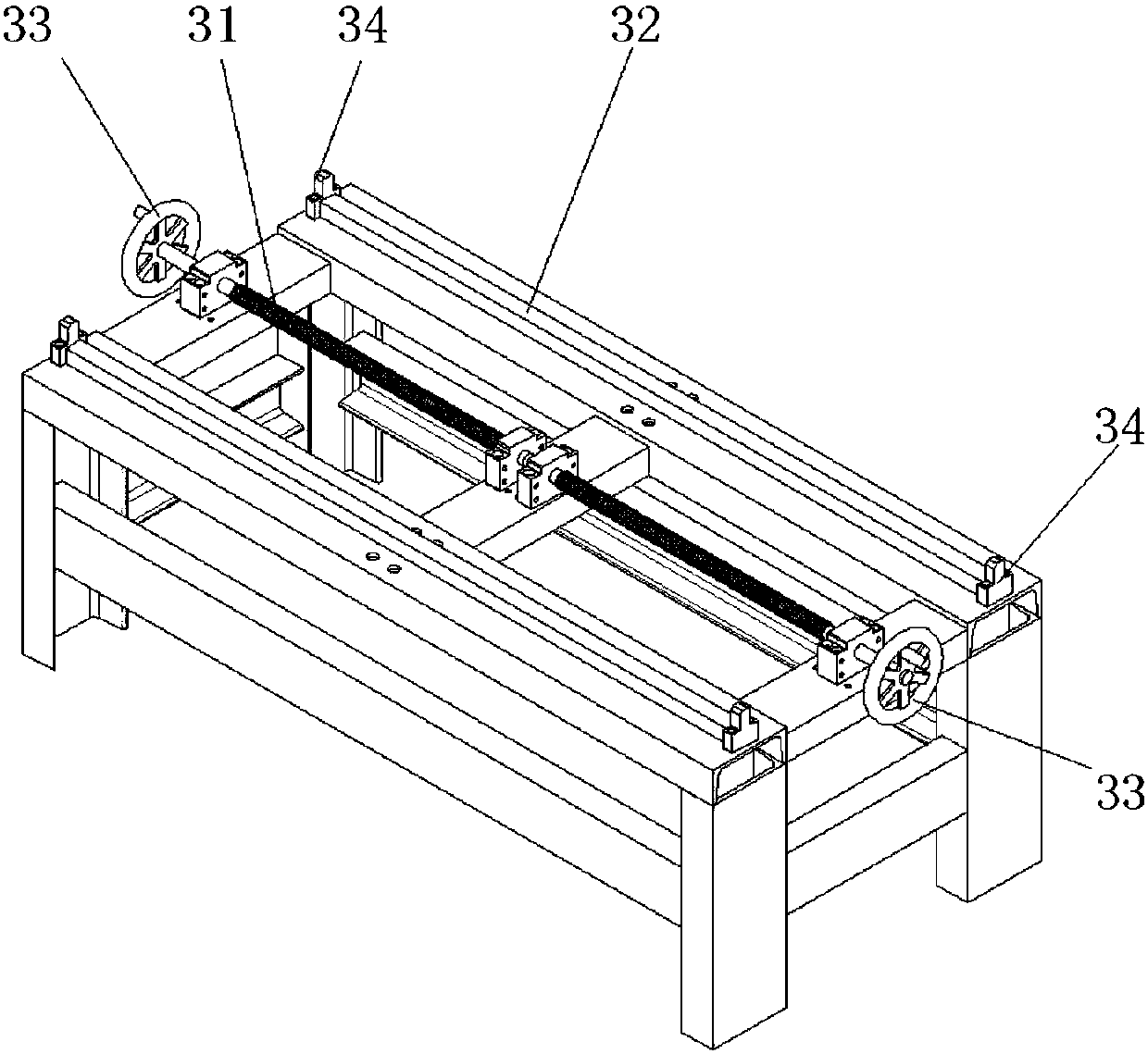

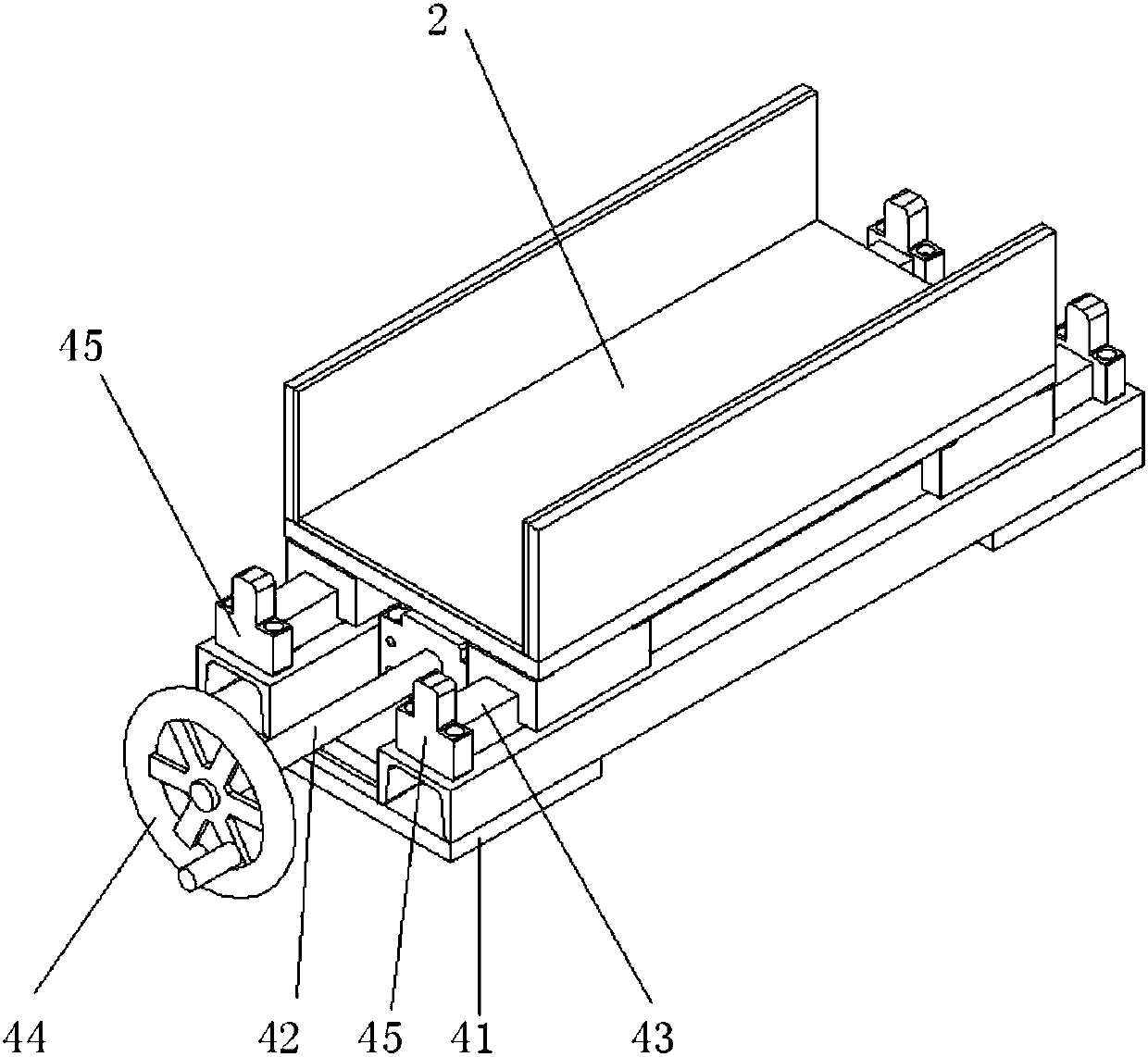

[0024] like Figure 1 to Figure 3 As shown, the transformer iron yoke insertion platform of this embodiment includes a base 1, a transformer movable table 2, a horizontal linear module 3 and a vertical linear module 4, the horizontal linear module 3 is arranged on the base 1, and the vertical linear module 4 is installed on the horizontal moving linear module 3, and the transformer movable table 2 is installed on the vertical moving linear module 4. The horizontal moving linear module 3 drives the vertical moving linear module 4 to move horizontally, and the vertical moving linear module 4 drives the transformer movable table 2 longitudinally. move.

[0025] In this embodiment, the ordinary fixed inserting platform is changed to an adjustable inserting platform that can move horizontally and horizontally and vertically. The transfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com