A copper-doped tio with an extremely low bandgap 2 Preparation method of nanoparticles

A nanoparticle and copper doping technology, applied in the field of spectroscopy, can solve the problem of low band gap energy value and achieve the effect of low band gap energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

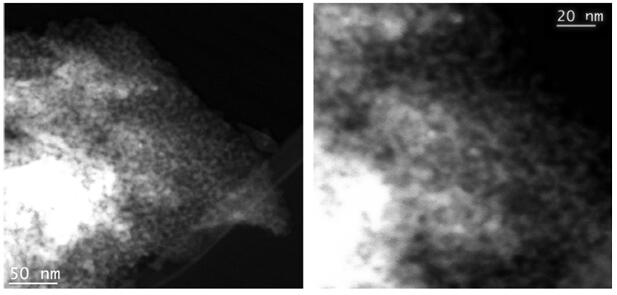

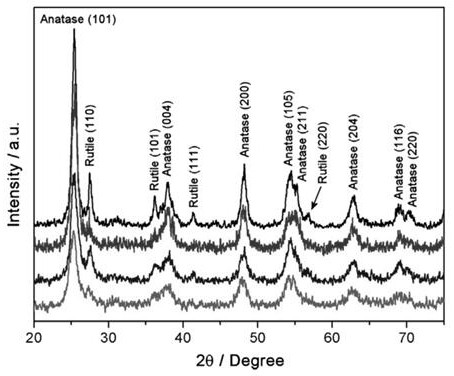

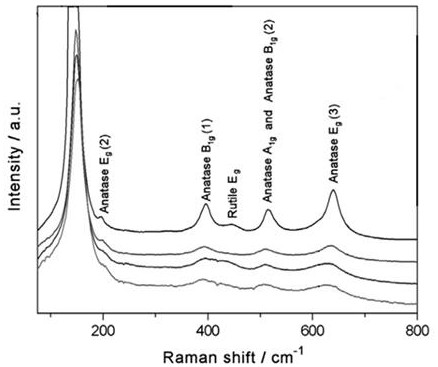

Image

Examples

Embodiment 1

[0020] A copper-doped TiO with an extremely low bandgap 2 A method for preparing nanoparticles, specifically comprising the following steps:

[0021] (1) Add 2g of CuCl 2 • 2H 2 Put O into 100mL of water at 2°C to obtain liquid A;

[0022] (2) Under the condition of magnetic stirring, add 45mL of titanium tetra-n-butoxide dropwise to the liquid A in step (1), the dropping speed is 0.3mL / s, and continue to stir for 30min after the dropwise addition to obtain the liquid B, the magnetic stirring speed 1400rpm;

[0023] (3) Add 4 mL of nitric acid dropwise to liquid B in step (2), the mass fraction of nitric acid is 60%, and the dropping rate of nitric acid is 0.1 mL / s, and continue stirring for 30 minutes after the addition is completed to obtain liquid C;

[0024] (4) Liquid C in step (3) is dried on a vacuum rotary suction cup at 50°C, and then heated to 90°C on a vacuum rotary suction cup to dry until the water is completely eliminated;

[0025] (5) The product of step (4...

Embodiment 2

[0028] A copper-doped TiO with an extremely low bandgap 2 A method for preparing nanoparticles, specifically comprising the following steps:

[0029] (1) Add 5g of CuCl 2 • 2H 2 Put O into 100mL of water at 4°C to obtain liquid A;

[0030] (2) Under the condition of magnetic stirring, add 48mL of titanium tetra-n-butoxide dropwise to liquid A in step (1), and continue to stir for 35 minutes after the addition is completed. The dropping speed of titanium tetra-n-butoxide is 0.5mL / s, and For liquid B, the magnetic stirring speed is 1500rpm;

[0031] (3) Add 5 mL of nitric acid dropwise to liquid B in step (2), the mass fraction of nitric acid is 65%, and the dropping speed of nitric acid is 0.15 mL / s, and continue stirring for 35 minutes after the addition is completed to obtain liquid C;

[0032] (4) Liquid C in step (3) is dried on a vacuum rotary suction cup at 55°C, and then heated to 95°C on a vacuum rotary suction cup to dry until the water is completely eliminated;

...

Embodiment 3

[0035] A copper-doped TiO with an extremely low bandgap 2 A method for preparing nanoparticles, specifically comprising the following steps:

[0036] (1) Add 8g of CuCl 2 • 2H 2 Put O into 100mL of water at 5°C to obtain liquid A;

[0037] (2) Under the condition of magnetic stirring, add 50mL of titanium tetra-n-butoxide dropwise to the liquid A in step (1), and continue to stir for 40 minutes after the addition is completed. The dropping speed of titanium tetra-n-butoxide is 0.6mL / s, and For liquid B, the magnetic stirring speed is 1600rpm;

[0038] (3) Add 6 mL of nitric acid dropwise to liquid B in step (2), the mass fraction of nitric acid is 70%, and the dropping speed of nitric acid is 0.2 mL / s, and continue stirring for 40 minutes after the addition is completed to obtain liquid C;

[0039] (4) Liquid C in step (3) is dried on a vacuum rotary suction cup at 60°C, and then heated to 100°C on a vacuum rotary suction cup to dry until the water is completely eliminated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com