Visible-light response type nanometer TiO2/starch composite membrane, preparation method and application thereof

A starch composite film, visible light technology, applied in application, food preservation, fruit and vegetable preservation, etc., can solve the problems of narrow spectral response range, difficult application in the field of fruit and vegetable storage and packaging, and difficult powder recovery, etc., to improve mechanical properties and water resistance. , Good visible light response activity, long-lasting photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

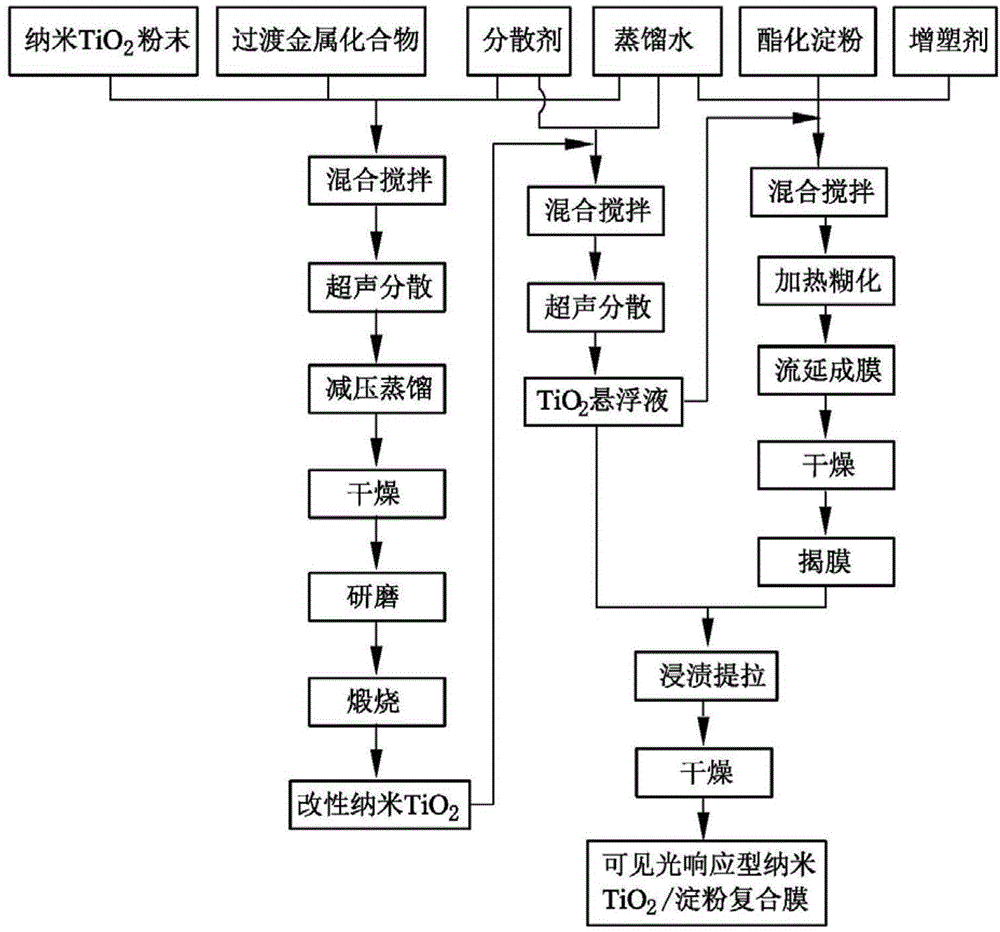

Method used

Image

Examples

Embodiment 1

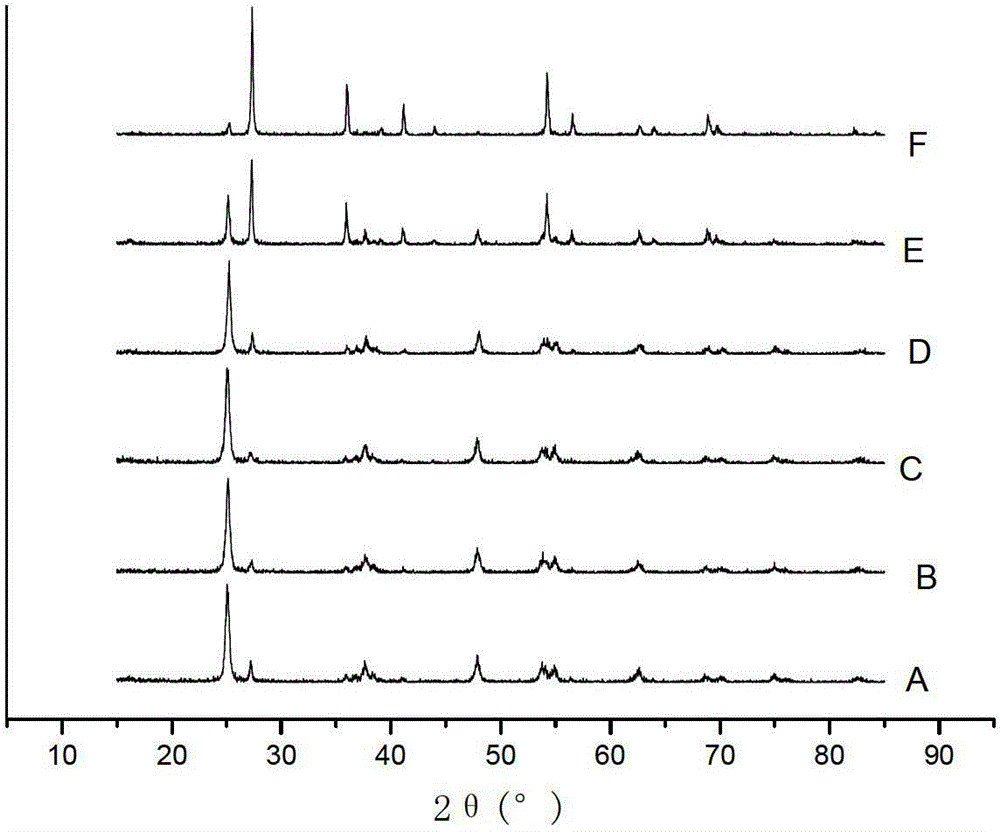

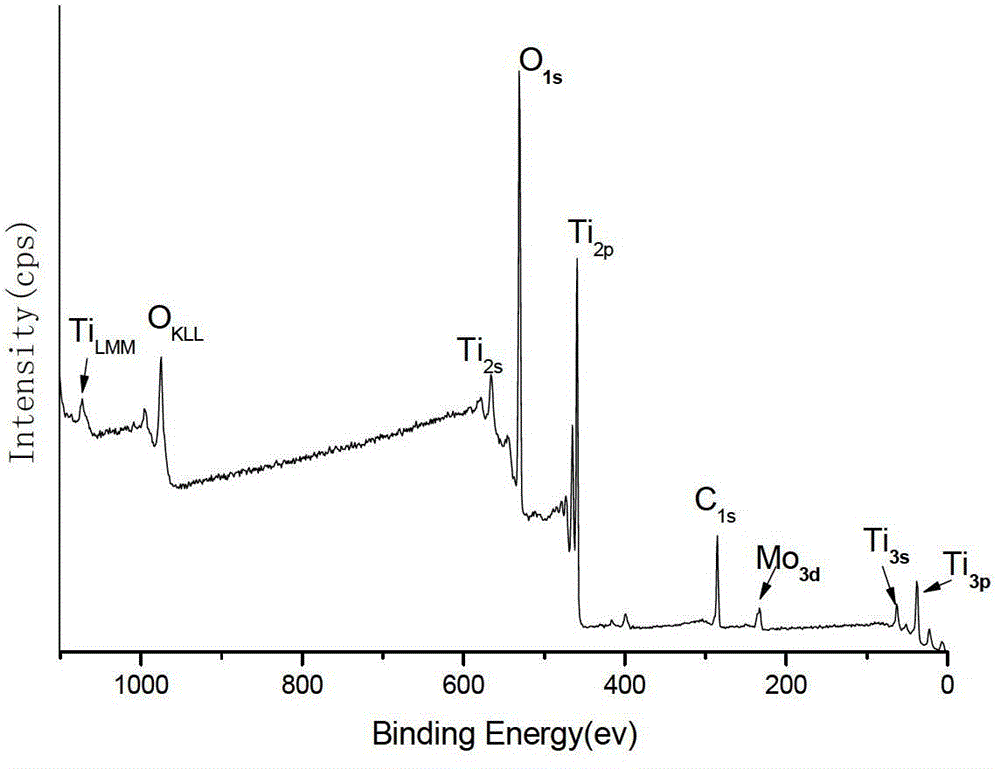

[0027] (1) Visible light-responsive modified nano-TiO 2 Preparation: Weigh 1.082g ammonium heptamolybdate (according to the mole percentage of Mo element in ammonium heptamolybdate and Ti element in titanium dioxide is 0.5%) and 0.015g sodium dodecylsulfonate (SDS) into a beaker , add 100mL of distilled water, and make it fully dissolved by magnetic stirring. Then weigh 2g nano-TiO 2 P25 (P25 powder from Germany’s Degussa branch) was slowly added into the beaker, stirred magnetically for 2 hours, then dispersed ultrasonically for 40 minutes, and distilled under reduced pressure for 30 minutes with a rotary evaporator at a vacuum degree of 0.1Mpa and a water bath temperature of 60°C, and then placed Dry in an oven at 85°C for 12 hours. Put the dried sample in an agate mortar and grind it continuously for 30 minutes, put the ground sample into a muffle furnace for calcination at 600°C for 2 hours, and obtain a visible light-responsive modified nano-TiO 2 (Mo-P25 powder), its ...

Embodiment 2

[0034] (1) Visible light-responsive modified nano-TiO 2 Preparation: Weigh 4.326g of ammonium heptamolybdate (according to the mole percentage of Mo element in ammonium heptamolybdate and Ti element in titanium dioxide is 2%) and 0.013g SDS into a beaker, add 100mL of distilled water, through magnetic Stir to fully dissolve. Weigh again 2.017g nanometer TiO 2 (P25 powder from Germany’s Degussa branch) was slowly added to the beaker, stirred magnetically for 2 hours, then dispersed ultrasonically for 40 minutes, and distilled under reduced pressure for 30 minutes with a rotary evaporator at a vacuum degree of 0.1Mpa and a water bath temperature of 60°C, and then placed in Dry in an oven at 85°C for 12h. Put the dried sample into an agate mortar and grind it continuously for 30 minutes, then put the ground sample into a muffle furnace for calcination at 500°C for 2 hours to obtain a visible light-responsive modified nano-TiO 2 (Mo-P25 powder).

[0035] (2) Preparation of com...

Embodiment 3

[0041] (1) Visible light-responsive modified nano-TiO 2 Preparation: Weigh 1.732g ammonium heptamolybdate (according to the mole percentage of Mo element in ammonium heptamolybdate and Ti element in titanium dioxide is 0.8%) and 0.014g sodium dodecylsulfonate (SDS) into a beaker , add 100mL of distilled water, and make it fully dissolved by magnetic stirring. Weigh 2.008g nanometer TiO 2 (P25 powder from Germany’s Degussa branch) was slowly added into the beaker, stirred magnetically for 2 hours, then dispersed ultrasonically for 40 minutes, and distilled under reduced pressure for 30 minutes with a rotary evaporator at a vacuum degree of 0.1Mpa and a water bath temperature of 60°C, and then placed in Dry in an oven at 85°C for 12h. Put the dried sample into an agate mortar and grind it continuously for 30 minutes, then put the ground sample into a muffle furnace for calcination at 500°C for 2 hours to obtain a visible light-responsive modified nano-TiO 2 (Mo-P25 powder). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com