Skirting line anti-shedding hook fixing structure and installation method thereof

A fixed structure and anti-shedding technology, applied in the direction of building structure, construction, etc., can solve the problems such as affecting the overall beauty of the skirting, the surface paint film of the skirting being easily damaged, easy to loosen and fall off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

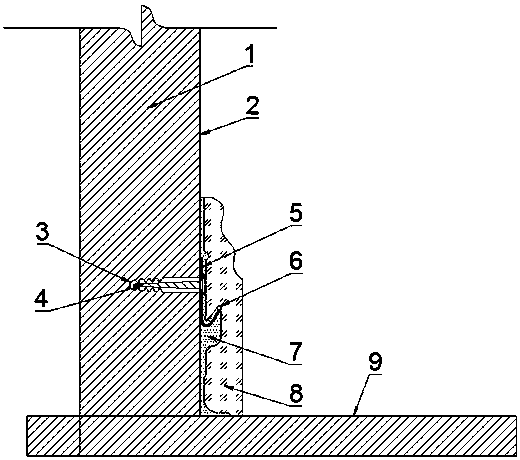

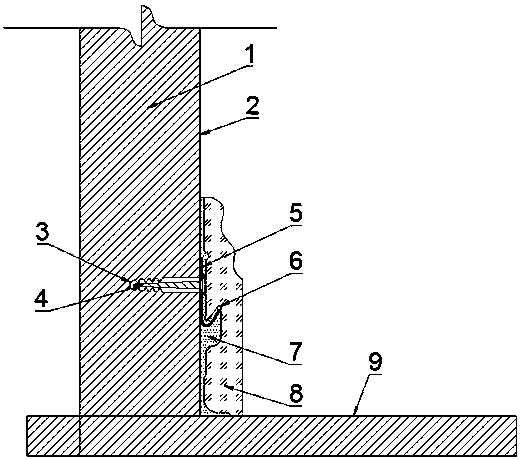

[0028] see figure 1 As shown, in this embodiment, a skirting line anti-falling hook fixing structure includes nylon expansion tube 3, self-tapping screw 4, J-shaped anti-falling hook member 5, foaming agent 7 and skirting line 8, The inner surface of the skirting line 8 is provided with an anti-deformation hook groove 6 in the shape of an inner hook, and the anti-deformation hook groove 6 is 45°. The fall-off hook 5 is fixed on the bottom side of the wall 1 through the nylon expansion tube 3 and the self-tapping screw 4. The surface of the wall 1 is provided with a coating layer 2, and the wall 1 is provided with a horizontal positioning elastic line and a marking fixed point position. A drill hole is set at the fixed point, and the nylon expansion tube 3 is embedded in the drill hole. The self-tapping screw 4 passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com