Dispenser

A technology of injector and converter, which is applied in wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve problems such as poor stability, high requirements for sealing performance, and high requirements for high temperature resistance, and achieve operating costs The effect of lowering, good working stability and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

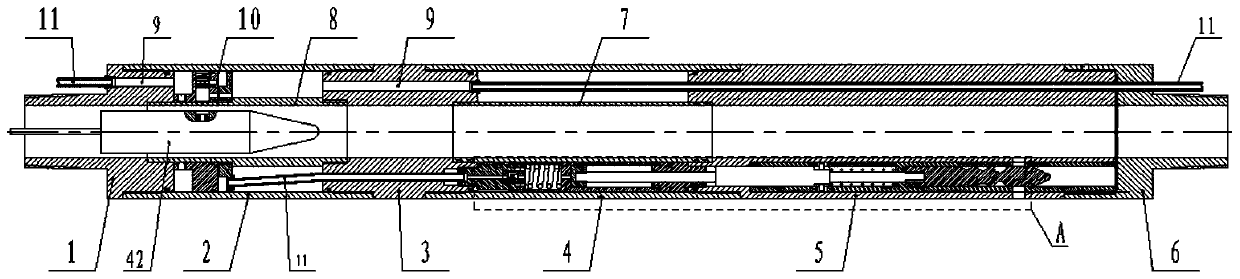

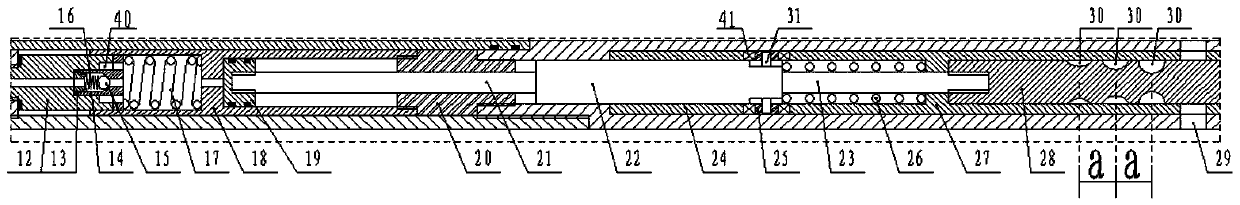

[0034]The present invention includes an upper joint 1, an upper cylinder 2, an adapter 3, a lower cylinder 4, an installation body 5, a lower joint 6, an upper central pipe 8 and a lower central pipe 7, an upper joint 1, an upper cylinder 2, an adapter 3, a lower The barrel 4 , the installation body 5 and the lower joint 6 are screwed together from top to bottom to form the casing of the dispenser.

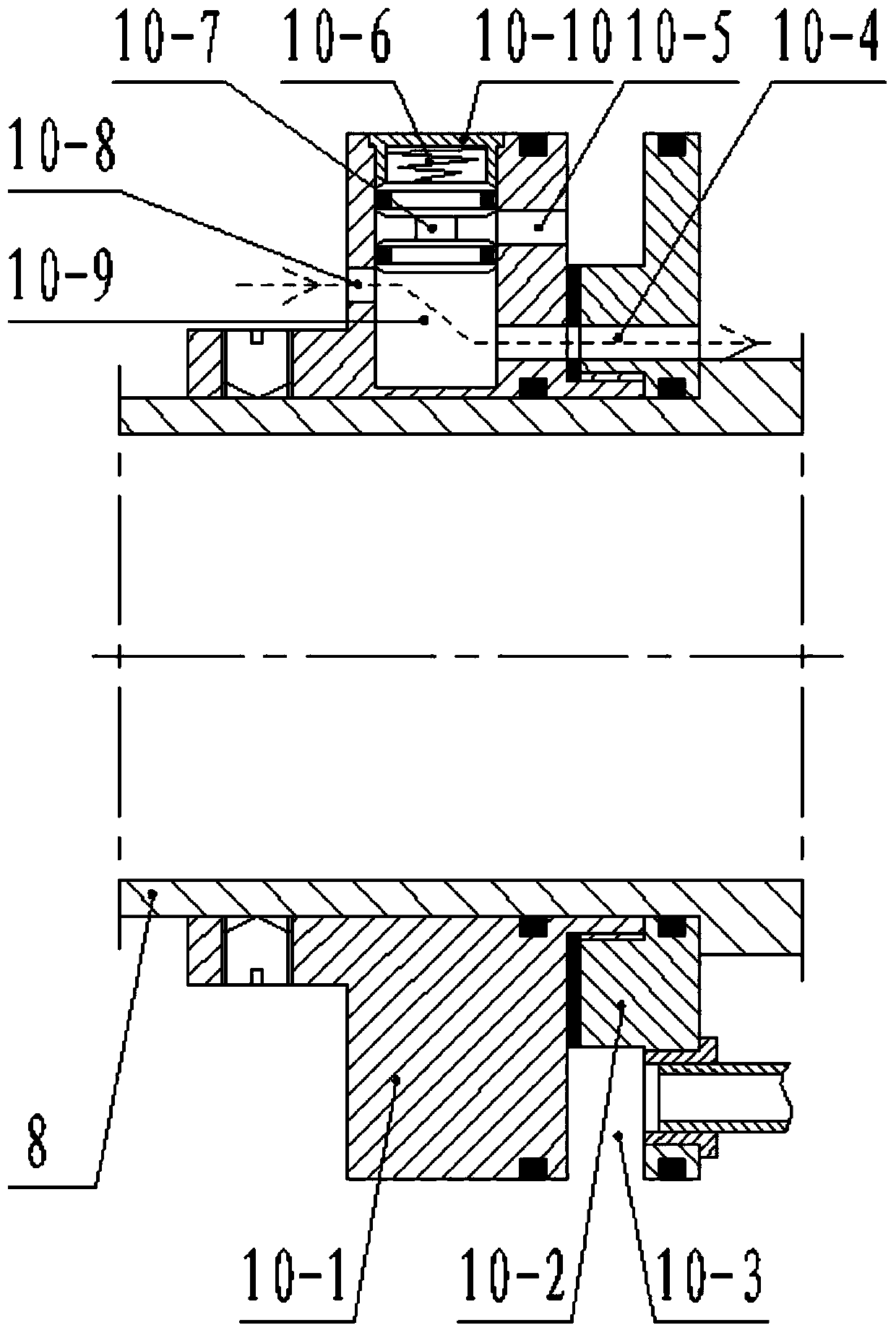

[0035] The upper end of the upper central pipe 8 is inserted into the upper joint 1, and the lower end of the upper central pipe 8 is screwed to the adapter 3, thereby forming an annular space between the upper central pipe 8 and the upper cylinder 2. A gas circuit converter 10 is installed in the space, and the gas circuit converter 10 is fixed on the upper central tube 8 through a top wire;

[0036] Both the upper joint 1 and the adapter 3 are provided with a linear air chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com