A small wind speed precision control method for low speed return wind tunnel

A precision control and small wind speed technology, applied in the field of wind tunnel experiments, can solve the problems of large precision control error, failure to start the wind speed control system, and no longer applicable, so as to expand the experimental range and improve the small wind speed control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

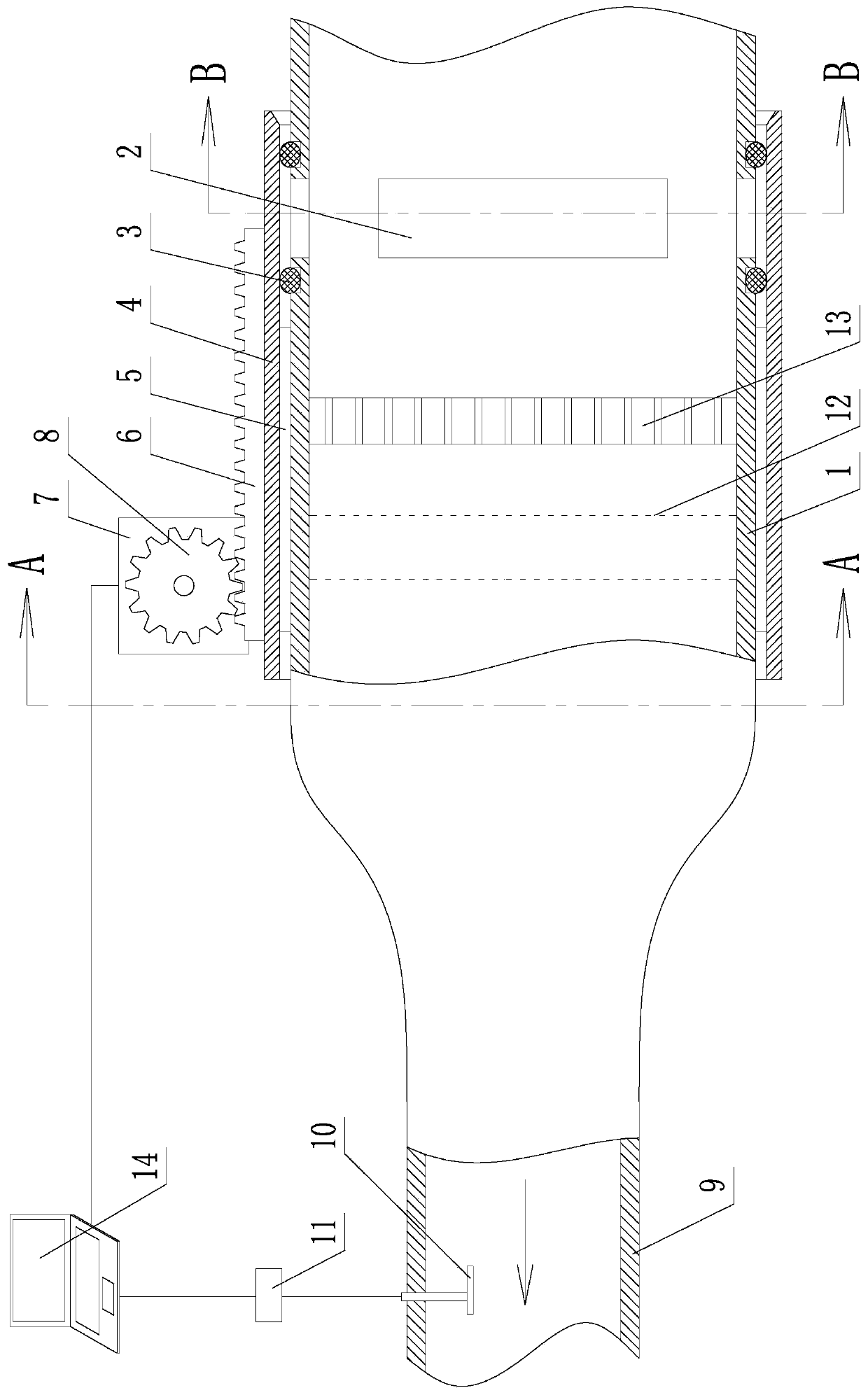

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] A low-speed backflow wind tunnel precision control method for small wind speeds, comprising the following steps:

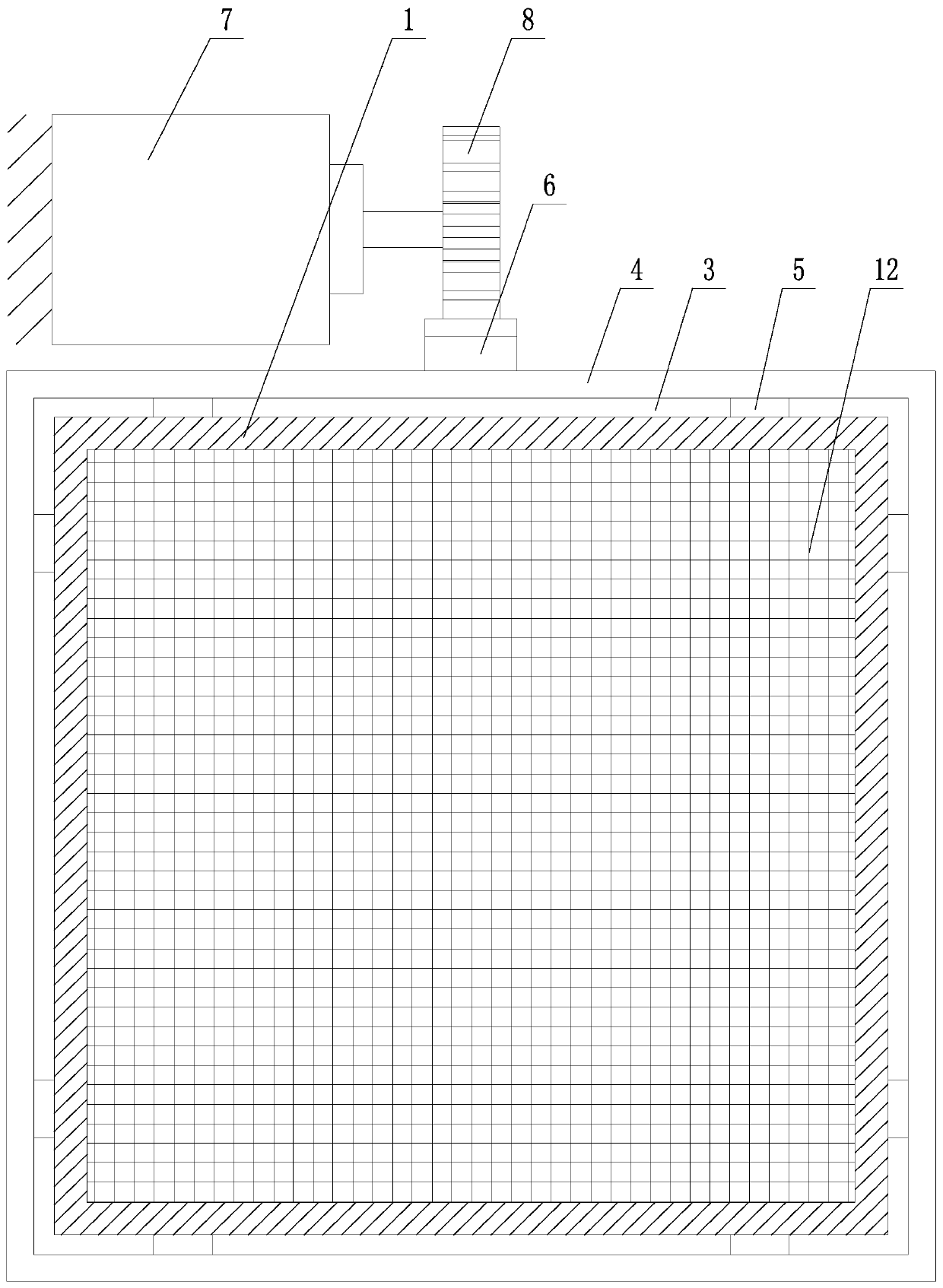

[0027] Step 1: first modify the wall 1 of the stable section, and process four vent holes 2 on the wall 1 of the stable section, and the four vent holes 2 are evenly distributed on the wall 1 of the stable section along the circumferential direction;

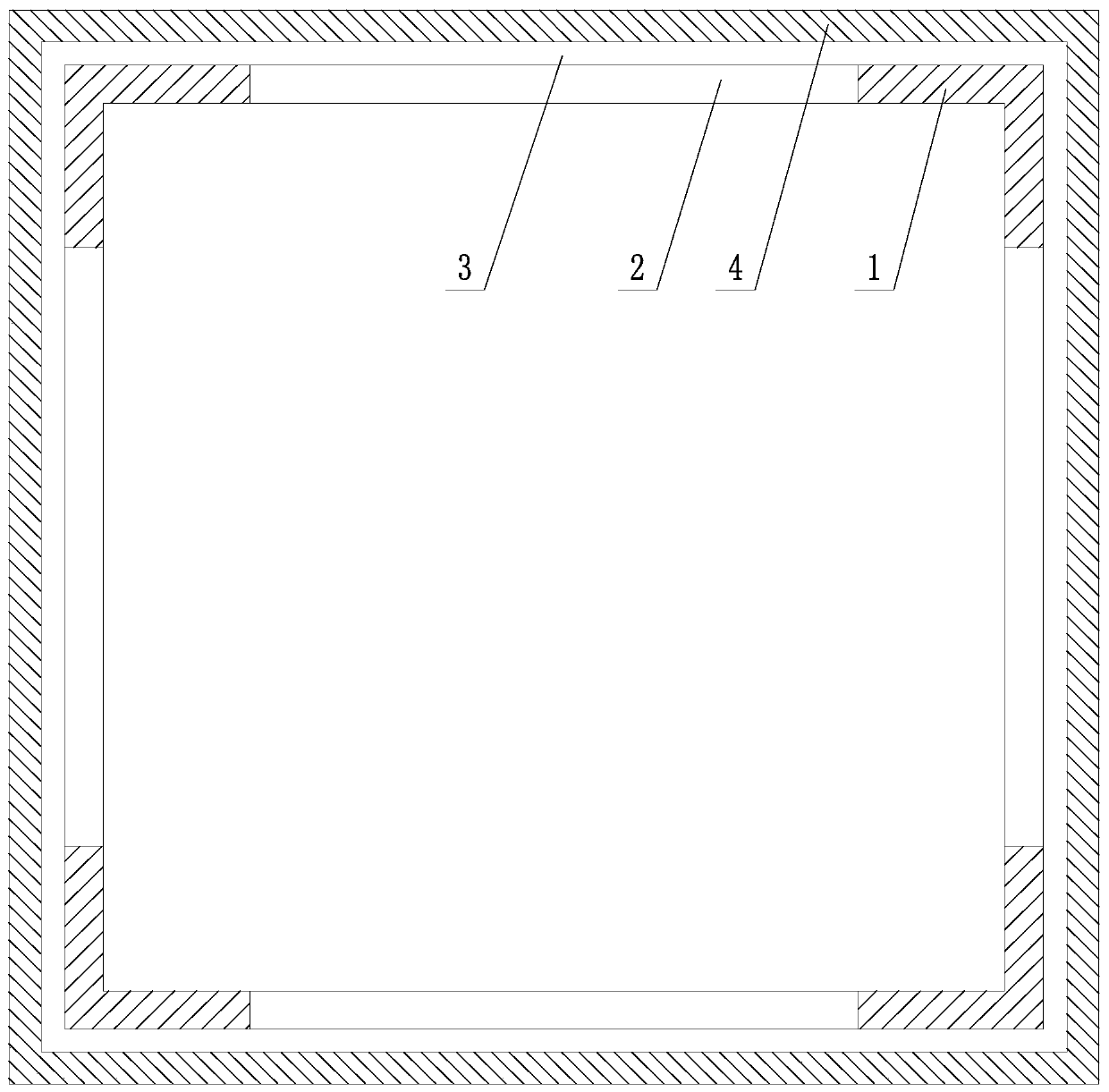

[0028] Step 2: Machining a sealing groove on the outer surface of the wall 1 of the stable section on both sides of the vent hole 2, and then embedding a sealing strip 3 in the sealing groove;

[0029] Step 3: Make a deflation volume control sleeve 4, put the deflation volume control sleeve 4 on the outer side of the stable section hole wall 1, and set several A guide rail 5, the guide rail 5 is fixedly connected with the outer surface of the wall 1 of the stable se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com